Chapter 4 Installation and Wiring

PAGE 4-2

Review Chapters 1 and 2 prior to designing a System. If the requirements and specifications in these two

(2) Chapters are not addressed, there is a chance of degraded System performance.

WARNING: Follow Lockout/Tagout and other safety precautions when connecting and/or

disconnecting cabling, wiring, and equipment.

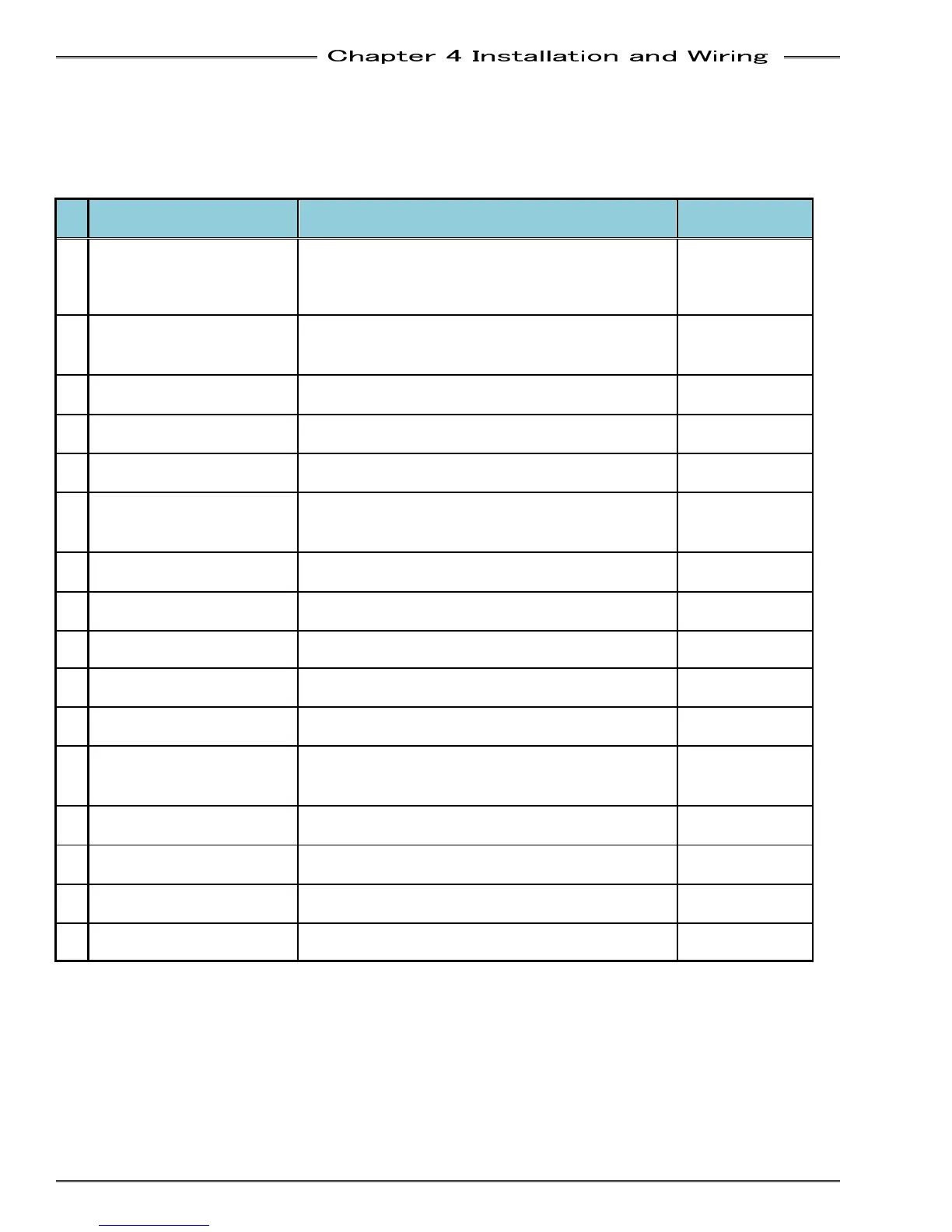

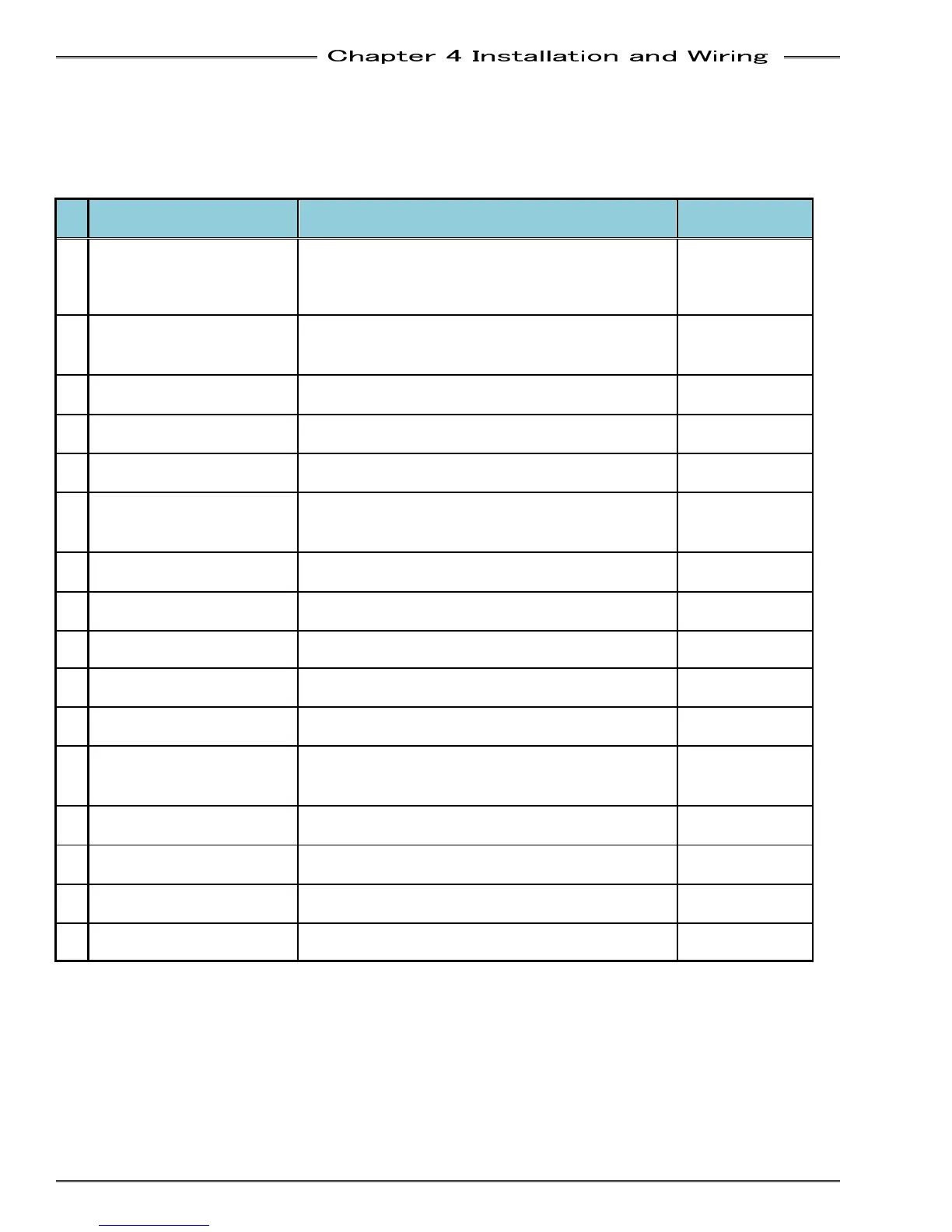

№

Item Contents Reference Page

1

Select correct tool size

Keep torque range between 50% and 75 % of

tool capability for best performance.

Ensure fastening bolt pattern and tool mounting

patterns are compatible.

PAGE 4-9

2

Design tool mounting plate,

pow

assemblies.

Design of mounting plate / powerhead requires

adherence to several specifications.

PAGE 4-16

3

Select correct controller

the tool selected.

Different tool motors require different Servo

Amplifiers. Ensure the correct one is selected.

PAGE 4-9~12

4

protectors.

Circuit protection for controller

separate from other units.

PAGE 4-20

5

Select an air handling unit

(as required).

Select an air handling unit applicable to the

environmental conditions (A/C, Heat Exch., etc.)

PAGE 4-3~6

6

Select an adequate PLC.

Select a PLC which will facilitate direct

connection to the AFC3000 System I/O (24 VDC).

PAGE 4-29

7

logic.

A PLC logic program can be written using signal

descriptions and timing charts provided.

PAGE 4-30~37

8

Select NEMA 12 enclosure.

Keep clearances among units according to the

recommended installation layout.

PAGE 4-7,8

9

Set MFC Unit dip switches.

Check the setting before connecting the Unit PAGE 48~50

10

Mount the controller

enclosure.

Refer to recommended installation layout. PAGE 4-8

11

Wire power connections.

Connect the power cables.

AND POLARITY PRIOR TO APPLYING POWER

PAGE 4-18,19

12

Wire I/O connections.

Connect all I/O wiring. VE

SOURCE AND POLARITY PRIOR TO

CONNECTION.

PAGE 4-25~28

13

Connect homerun cables.

, then connect cables for

every motor/resolver and preamplifier.

PAGE 4-22

14

Turn on the equipment.

VERIFY WIRING AND THE VOLTAGE OF ALL

POWER SUPPLIES PRIOR TO POWERING UP.

15

Input preset data.

Set the preset data for torque, angle, speed, time,

etc.

16

Verify normal function. Confirm normal operation.

Loading...

Loading...