FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 25

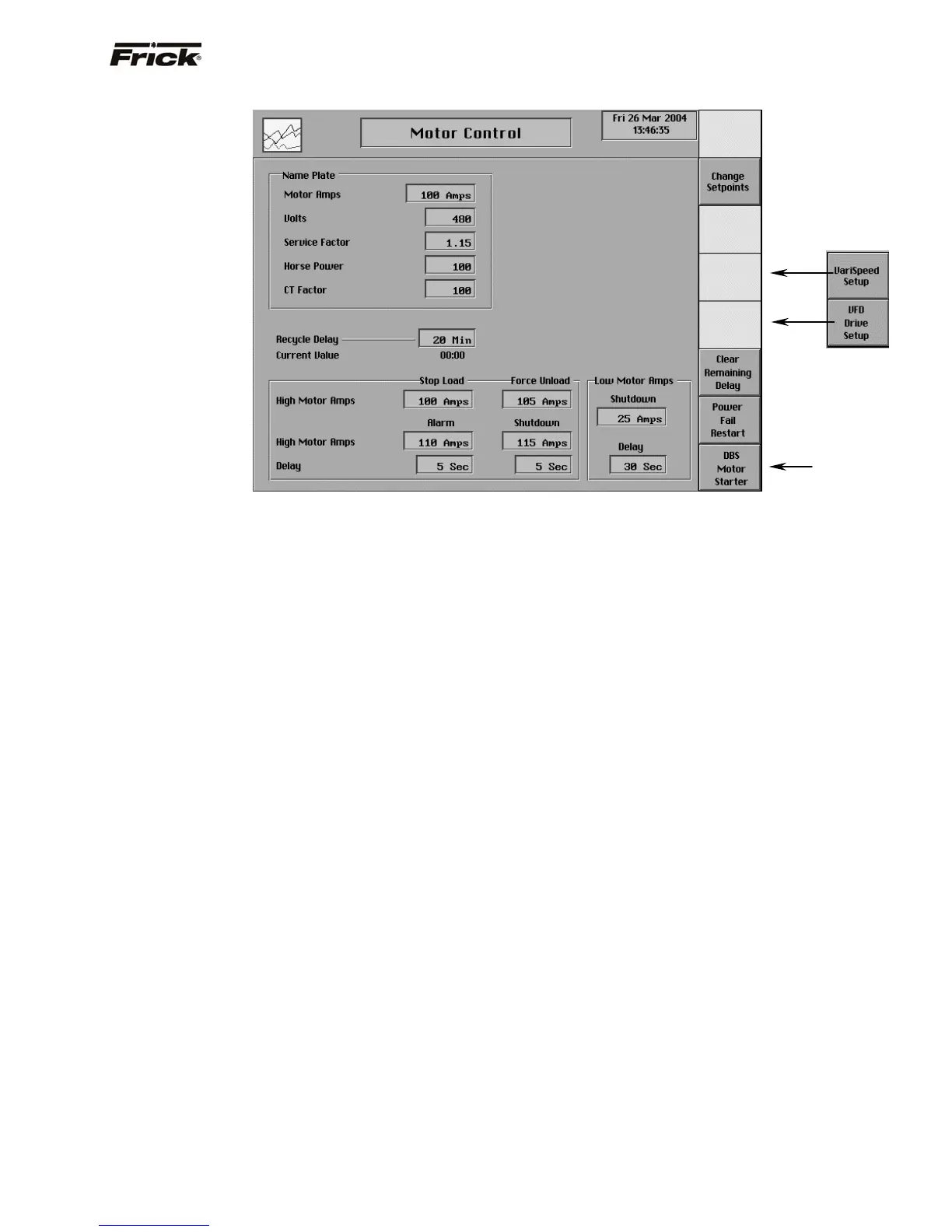

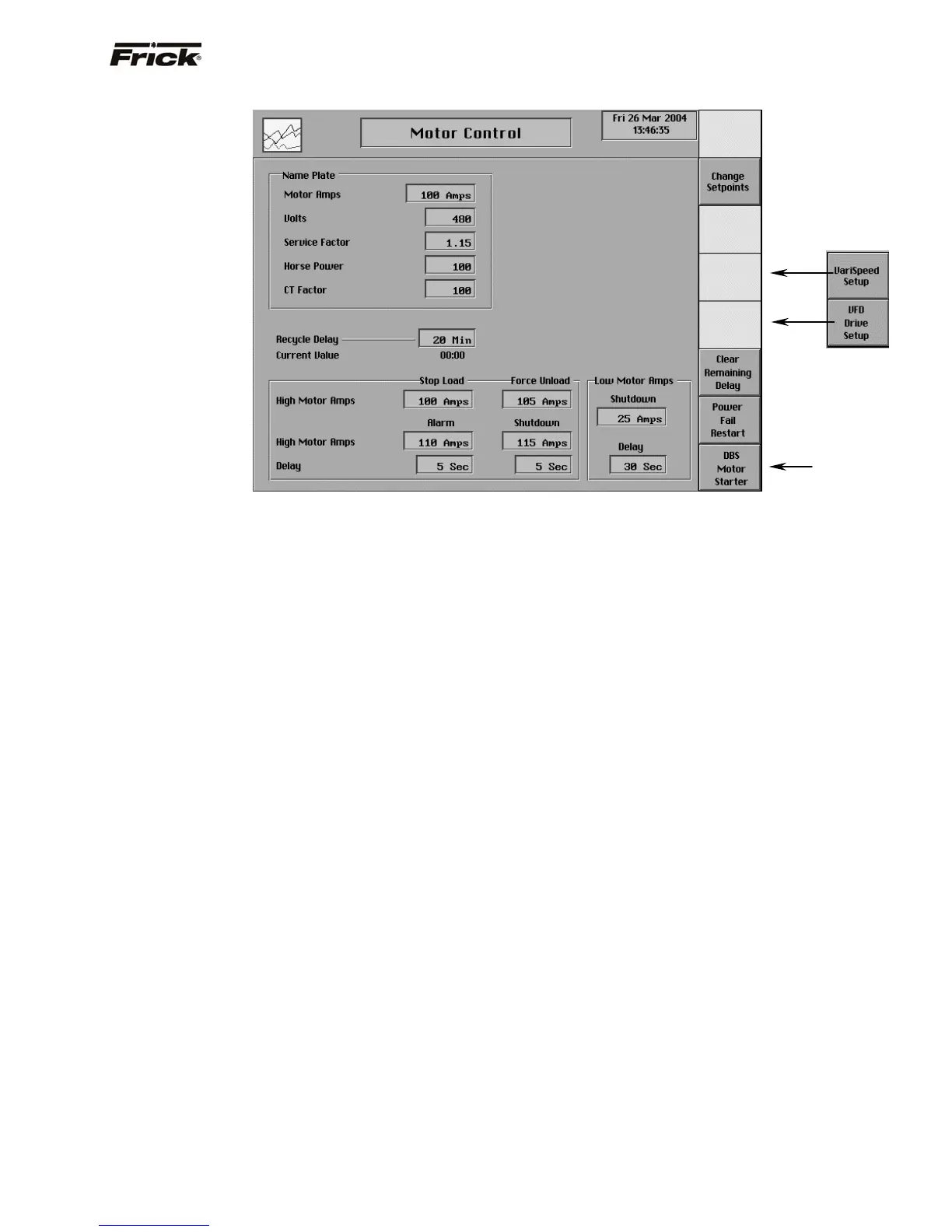

Motor Control

The following information should be recorded from the

motor nameplate:

• Motor Amps

• Volts

• Service Factor - Note: Not required if using RAM

DBS.

• Horse Power

• CT Factor - The Current Transformer Factor is

printed on the current transformer in the

compressor motor starter. Note: Not required if

using RAM DBS.

To verify that the CT has been sized properly,

use the following equation:

CTF = FLA (Full Load Amps) x Service Factor x

1.1 = Recommended CT (Round up to next

highest 100 Amps)

EXAMPLE: FLA = 182 Amps

SF = 1.0

CTF = (182 x 1.0 x 1.1) = 200.2 >

Round up to 300 [use 300:5 CT]

The following setpoint is required for safe motor operation:

Recycle delay - Each time the compressor is started,

this value will be loaded into the Recycle Delay timer.

This time must elapse prior to allowing the

compressor to restart. The timer will time out while the

compressor is running or stopped since the Recycle

Delay is a start-to-start protection. The Recycle Delay

time is intended to prevent damage to the motor from

successive restarts.

NOTE: Consult Motor Manufacturer for the

recommended duration of the Recycle Delay.

The following setpoints are required for Motor Amps load

control:

High Motor Amps Stop Load - The compressor slide

valve will be prevented from loading until the Motor

Amps is less than this setpoint.

TYPICAL SETTING: Motor Amps Stop Load = FLA x

100%

High Motor Amps Force Unload - When the Motor

Amps is greater than or equal to this setpoint, the

compressor Slide Valve will be forced to unload until

the Motor Amps has dropped by greater than 1% of

this setpoint. For example, if this setpoint were 115

amps, then Force Unload = 115 x .01 = 1.15 amps.

This means that the Slide Valve will be forced to

unload until the Motors Amps has dropped by 1.15

amps.

TYPICAL SETTING: Motor Amps Force UnLoad =

FLA x 105%

High Motor Amps Alarm - If the Motor Amps is

greater than or equal to this setpoint, for the alarm

time delay, an alarm occurs.

High Motor Amps Shutdown - If the Motor Amps is

greater than or equal to this setpoint, for the shutdown

time delay, the compressor will shut down.

High Motor Amps Alarm Delay - The minimum time

in seconds that the Motor Amps is greater than or

equal to the High Motor Amps Alarm setpoint before

notification of the alarm.

High Motor Amps Shutdown Delay - The minimum

time in seconds that the Motor Amps is greater than

or equal to the High Motor Amps Shutdown setpoint

before the compressor will shut down.

Low Motor Amps Shutdown – This setpoint is used

to determine if the coupling has broken. If the Motor

Optional

Setup Keys

Optional

Setup Key

Loading...

Loading...