FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 89

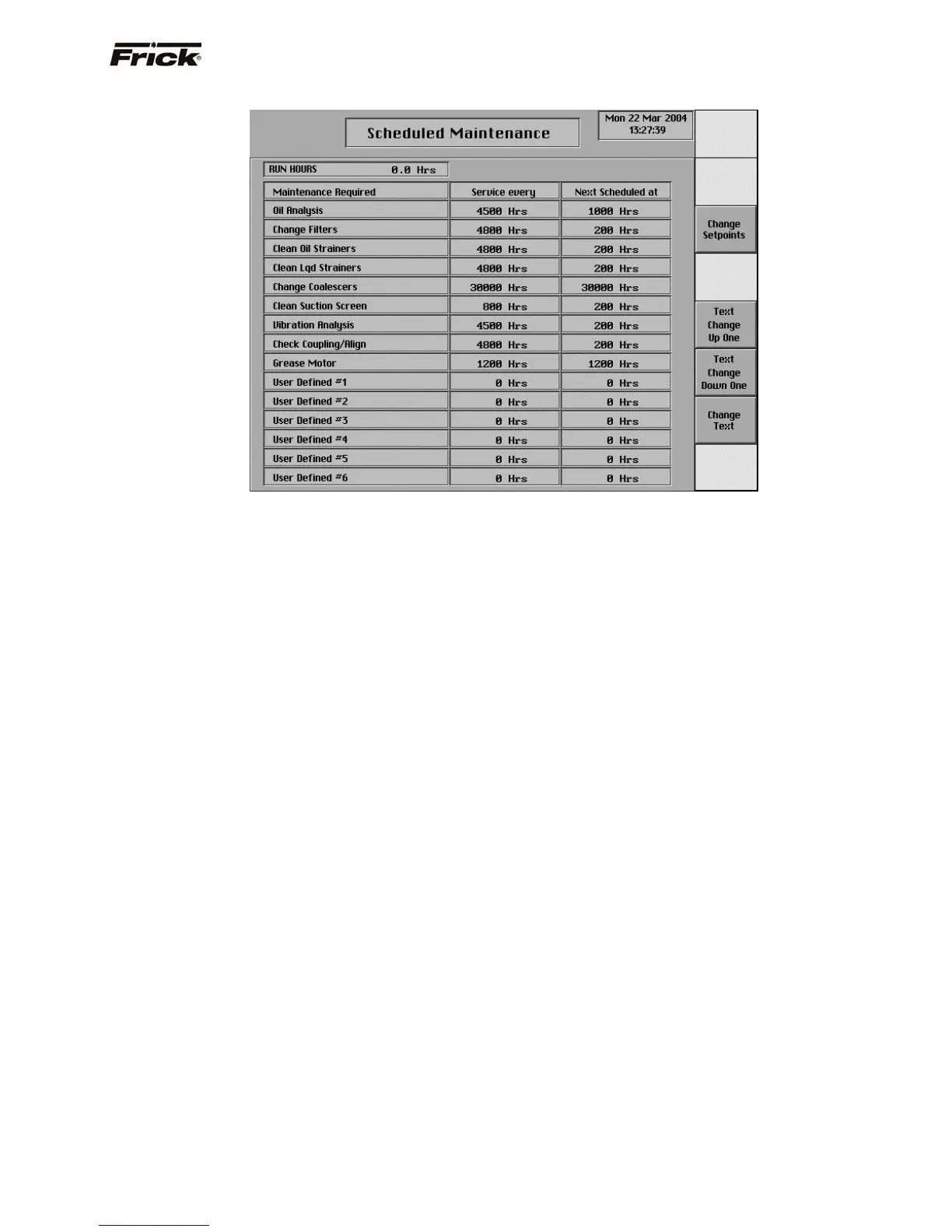

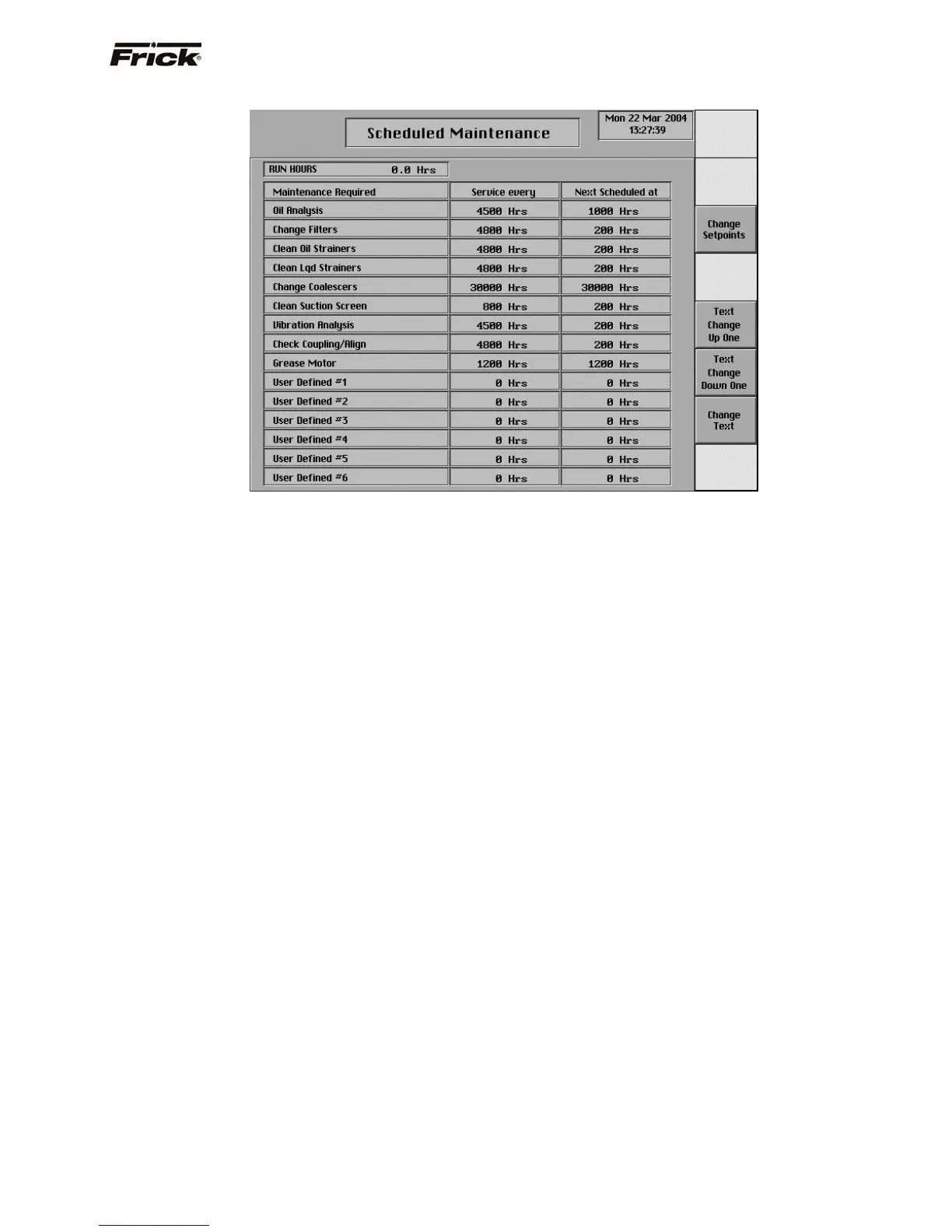

Scheduled Maintenance

This screen has been provided to help the service

technician and can be accessed from the service screen.

From here, the technician can view up to six (6) user

definable maintenance schedules (fifteen if Other

compressor type). Each of the schedules may be custom

named. This screen is based upon the Maintenance

Schedule that is provided in the IOM manual for the

specific compressor package.

The usage of this screen is that the user can define up to

fifteen different areas of compressor operation that they

would like to schedule routine maintenance for. As an

example, the above screen shows a row labeled as Oil

Analysis. The next column (Service Every) on the same

row has a value of 10000 Hrs. The last column (Next

Scheduled At) of this row has a value of 1000 Hrs. When

the compressor is running, this time value is being

clocked. After 1000 hours of compressor run time, an

alarm will be generated alerting the user with an alarm

message which will read Maintenance -- Oil Analysis. This

is to notify the operator that it is time to have the Oil

checked. At this point, the operator should notify the

proper maintenance personnel that the appropriate

maintenance be performed.

Once the alarm has occurred, the values for the row that

the alarm occurred in will be automatically updated, with

new values as predetermined by an internal programmed

maintenance schedule, based upon the type of

compressor. The values for the Next Scheduled at column

are based upon the Compressor Run Time hours.

The left most column is the user defined Maintenance

Required column. This is where custom names may be

entered for the various items that the user would like to

track.

A toggle key is provided for each of the data selections:

[Change Setpoints] - Pressing this key will highlight

the top box of the center column. Values in the range

of 0 - 11000 (hours) may be entered in the Service

every column (values of 10% of the IOM values 0-

999999, if other compressor type). Use the arrow

keys on the keypad to maneuver to the remaining

selectable boxes. Values in the Next Scheduled at

column are in the range of 0 - 999999 (hours).

[Text Change Up One] – Pressing this key causes

the box above the highlighted one in the Maintenance

Required column to become highlighted. Pressing this

key when the top box is already selected has no

affect.

[Text Change Down One] – Pressing this key causes

the box below the highlighted one in the Maintenance

Required column to become highlighted. Pressing this

key when the bottom box is already selected has no

affect.

[Change Text] – Upon using the [Text Change Up

One] or [Text Change Down One] keys to highlight a

box in the Required Maintenance column, pressing

this key allows the operator to change the name of

text within the box. An alphanumeric keypad screen

(see Alpha Select screen on the next page) will

replace the current screen. The user may type in a

custom name up to 20 characters long.

Loading...

Loading...