High RPM Alarm - If the RPM is greater than or

equal to this setpoint, for the alarm time delay, an

alarm occurs.

High RPM Shutdown - If the RPM is greater than or

equal to this setpoint, for the shutdown time delay, the

compressor will shut down.

High RPM Alarm Delay - The minimum time in

seconds that the RPM is greater than or equal to the

High RPM alarm setpoint before notification of the

alarm.

High RPM Shutdown Delay - The minimum time in

seconds that the RPM is greater than or equal to the

High RPM shutdown setpoint before the compressor

will shut down.

Low RPM Stop Load - If the RPM is less than or

equal to this setpoint, the compressor will be

prevented from further loading until the RPM is

greater than this setpoint. This setpoint helps avoid

forced unloading.

Low RPM Force Unload - If the RPM is less than or

equal to this setpoint, the compressor will be forced to

unload until the RPM is greater than this setpoint.

This setpoint helps avoid a low RPM alarm or

shutdown.

Low RPM Alarm - If the RPM is less than or equal to

this setpoint, for the alarm time delay, an alarm

occurs.

Low RPM Shutdown - If the RPM is less than or

equal to this setpoint, for the shutdown time delay, the

compressor will shut down.

Low RPM Alarm Delay - The minimum time in

seconds that the RPM is less than or equal to the Low

RPM alarm setpoint before notification of the alarm.

Low RPM Shutdown Delay - The minimum time in

seconds that the RPM is less than or equal to the Low

RPM shutdown setpoint before the compressor will

shut down.

Confirmed Running (RPM) - The value that the RPM

is greater than or equal to consider the compressor

running.

Starting Maximum Delay - The time delay required

for the Slide Valve to unload below the Highest Slide

Valve position to allow starting the compressor

setpoint and the engine RPM’s to reach the confirmed

running RPM’s setpoint.

NOTE: See Electric, VFD, Engine, Turbine flowchart

for further information.

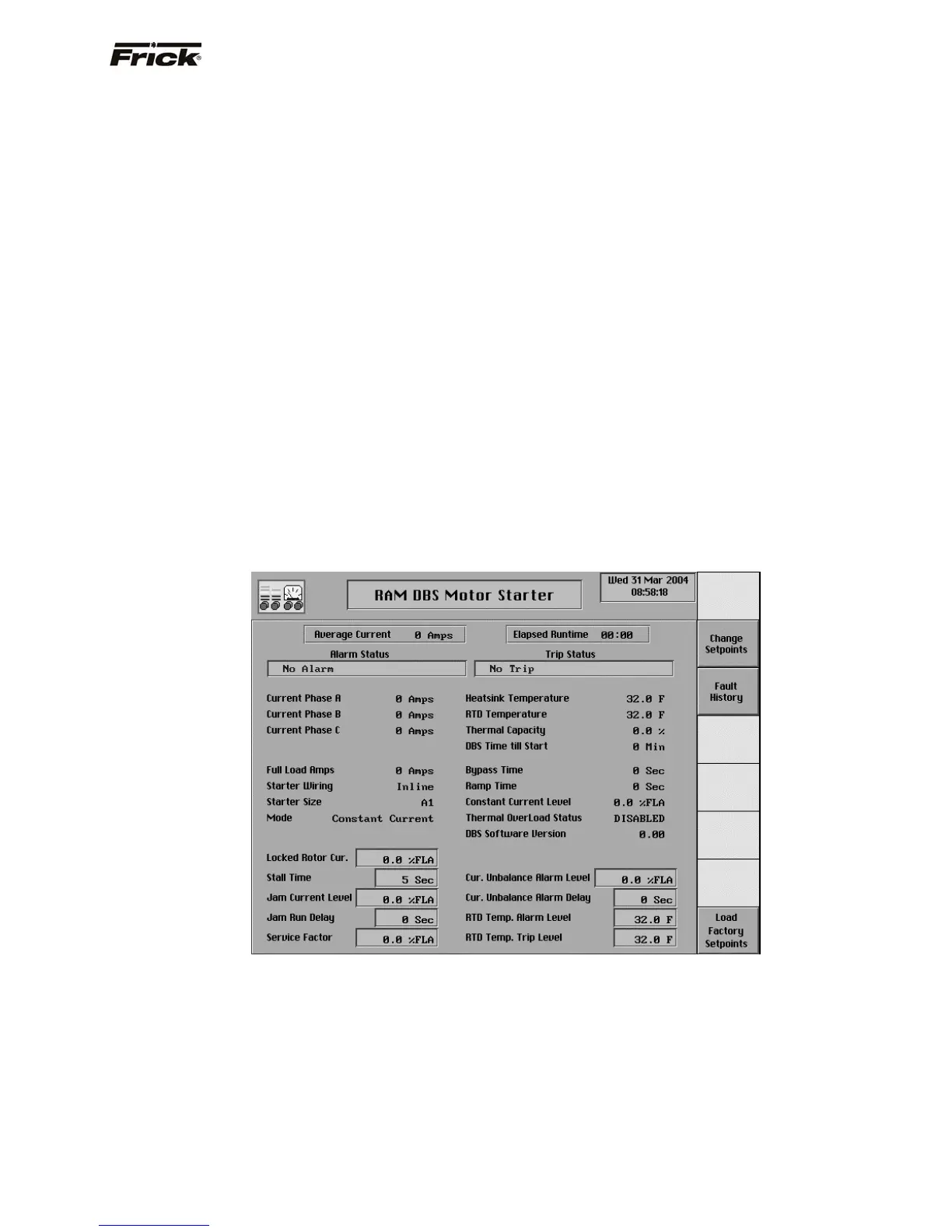

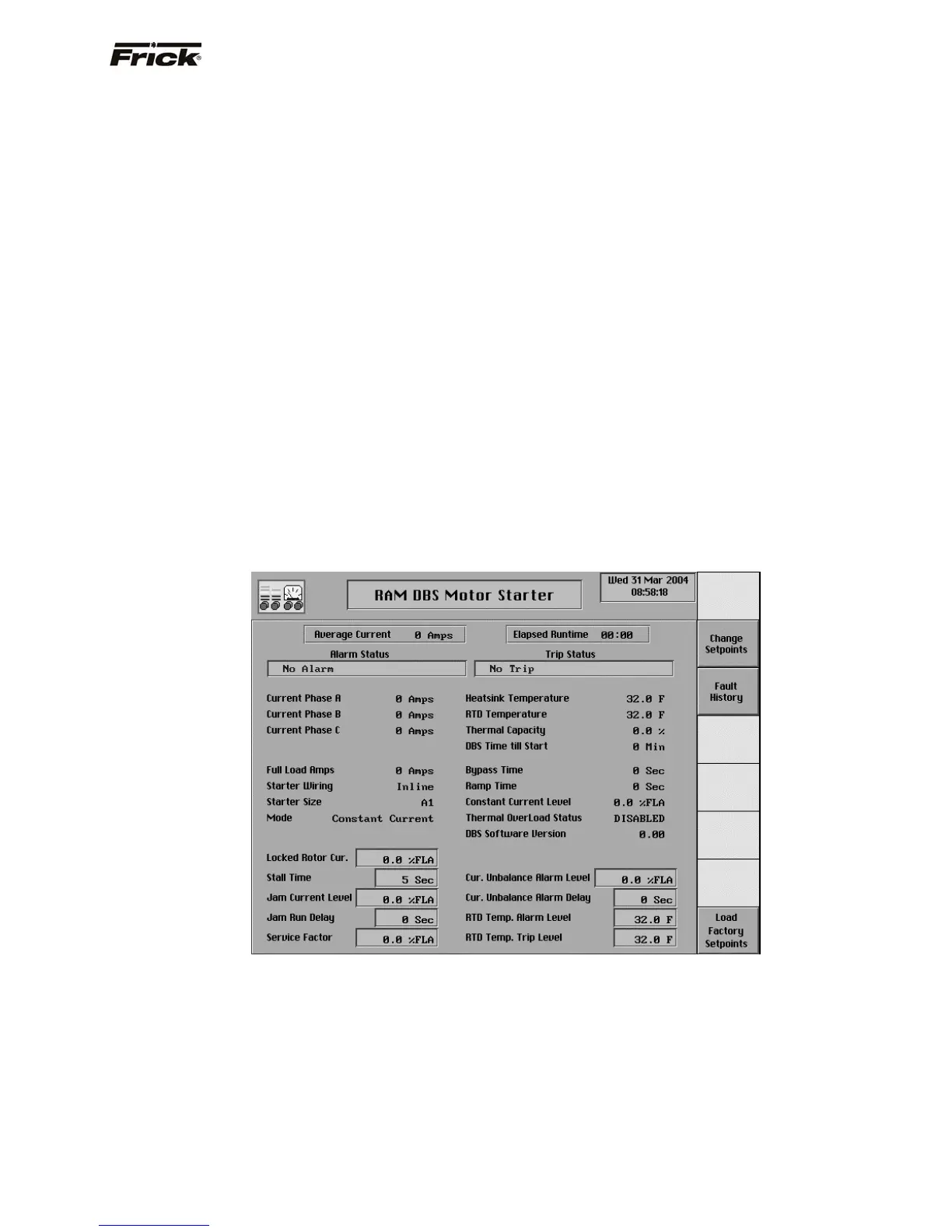

RAM DBS Motor Starter

This screen is available if a RAM DBS motor starter has

been set up for use with the Quantum™. The DBS

accelerates the motor in a smooth, stepless motion,

therefore it reduces supply voltage dip during motor start,

and mechanical shock on the compressor. Reference the

DBS Operator’s Guide and Instruction Manual or contact

RAM Industries Inc., in Leesport, Pennsylvania at 800-

220-8697 with any further questions concerning the setup

and operation of the RAM DBS.

The current system conditions of the RAM DBS are

displayed for monitoring. The Time Till Start value will also

be displayed on both the Motor Control screen and this

screen. This value and the current Recycle Delay timer

must be zero prior to allowing the compressor to restart.

These timers are intended to prevent damage to the motor

from successive restarts. Both timers can be cleared by

pressing the [Clear Remaining Delay] key on the Motor

Control screen. The Time Till Start is read from the RAM

DBS.

The following RAM DBS setpoints are modifiable from this

screen:

• Locked Rotor Current

• Stall Time

• Jam Current Level

FRICK QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 29

Loading...

Loading...