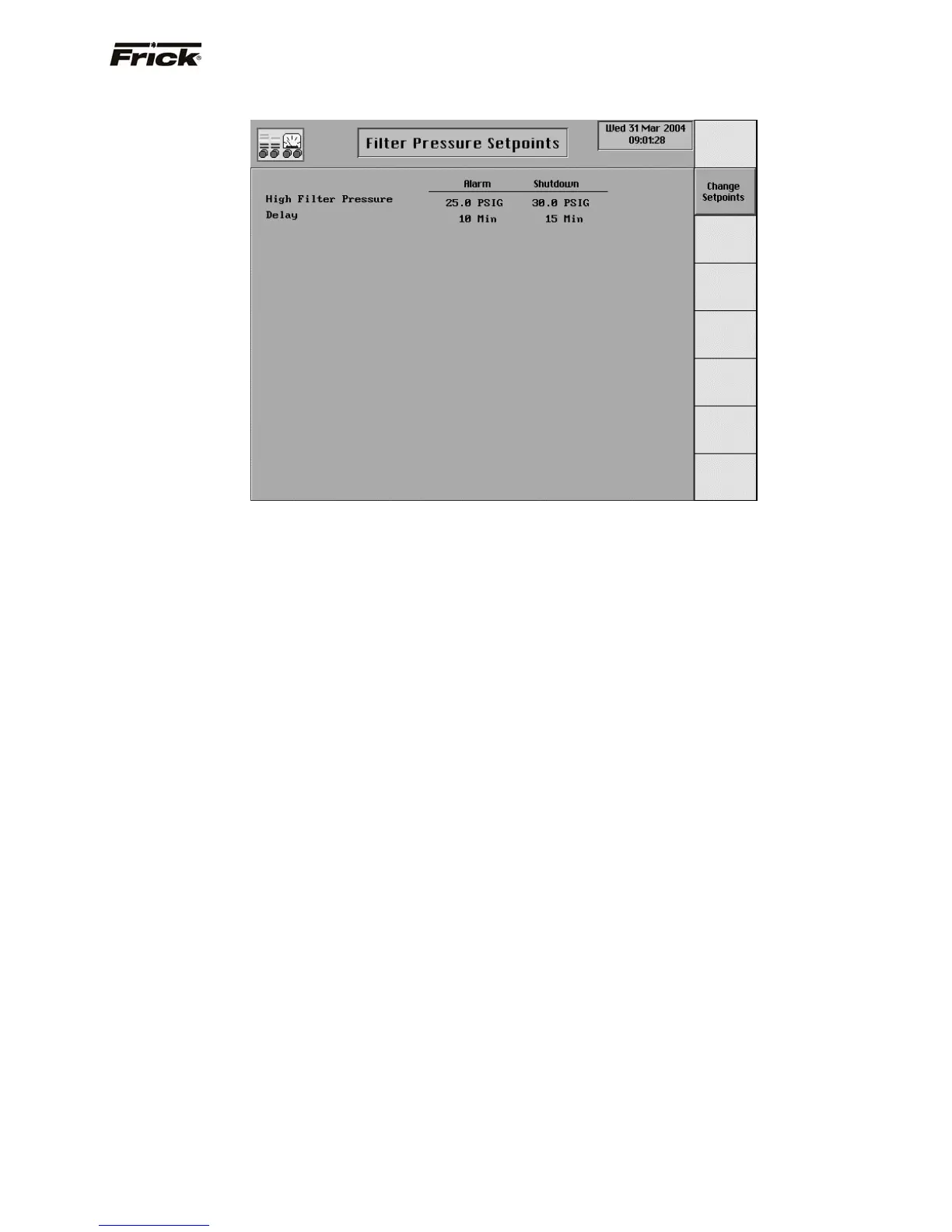

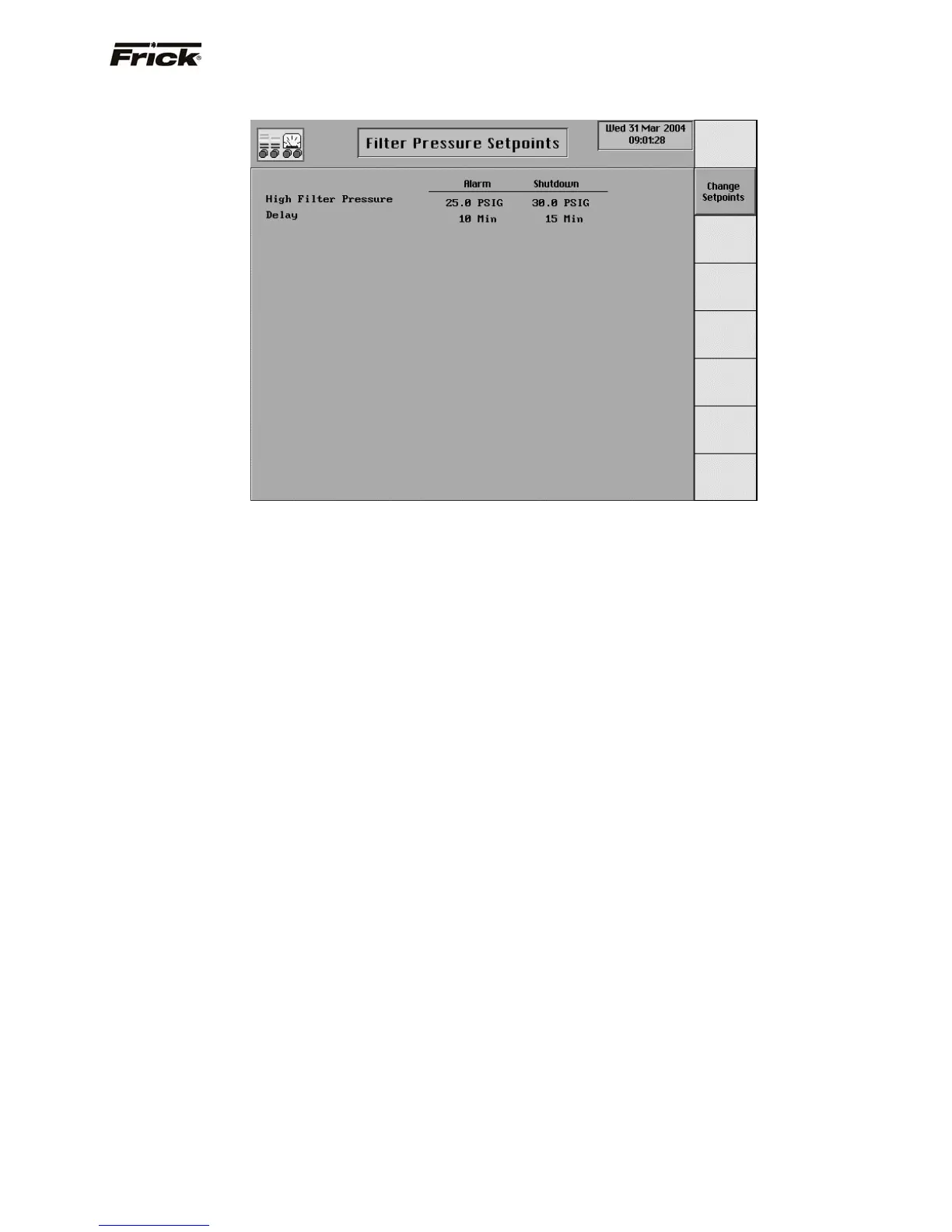

Filter Pressure Setpoints

This screen has the following setpoints:

High Filter Pressure Alarm - If the Filter Pressure is

greater than or equal to this setpoint, for the alarm time

delay, an alarm occurs.

High Filter Pressure Shutdown - If the Filter

Pressure is greater than or equal to this setpoint, for

the shutdown time delay, the compressor will shut

down.

High Filter Pressure Alarm Delay - The minimum

time in seconds that the Filter Pressure is greater than

or equal to the High Filter Pressure Alarm setpoint

before notification of the alarm.

High Filter Pressure Shutdown Delay - The

minimum time in seconds that the filter pressure is

greater than or equal to the High Filter Pressure

Shutdown setpoint before the compressor will shut

down.

Overview of the Oil Pump Operation

A Prelube Pump is turned on if the Slide Valve is too high.

While the compressor is running the Prelube Pump is

turned off. A Full Time Pump is always turned on while the

compressor is starting and running. The Cycling Pump is

cycled on and off while the compressor is running in

response to the pressure differential calculation. The

differential equals the Discharge Pressure reading minus

the Suction Pressure reading. The pump is turned on if

[Discharge – (1.4

k

* Suction)] < 35. The pump is turned off

if [Discharge – (1.4

k

* Suction)] > 45.

During the compressor stop cycle, the Oil Pump is used

for a postlube operation that is performed to help unload

the Slide Valve. During the postlube, the Oil Pump will be

turned on for five (5) minutes or until the Slide Valve is

unloaded to or below the Highest Slide Valve position to

allow starting the compressor setpoint. The compressor

can not be restarted unless the Slide Valve is less than the

Highest Slide Valve position to allow starting the

compressor setpoint. If the Slide Valve does not unload

below this setpoint within 5 minutes, the alarm message

Compressor Unload Failure - Alarm is issued.

Dual Pumps are enabled in Factory Setup. The lead pump

is the pump selected to be the first pump to run. If the lead

pump has a pump auxiliary failure, an alarm message is

issued and the other pump will be turned on. If the

compressor has a Low Oil Pressure Alarm failure, the

second pump will be turned on; then after a 30 seconds

delay, the lead pump will be turned off. If while the

compressor is running the second pump has an auxiliary

failure or low Oil Pressure is encountered, a shutdown

message and action is issued.

FRICK QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 35

Loading...

Loading...