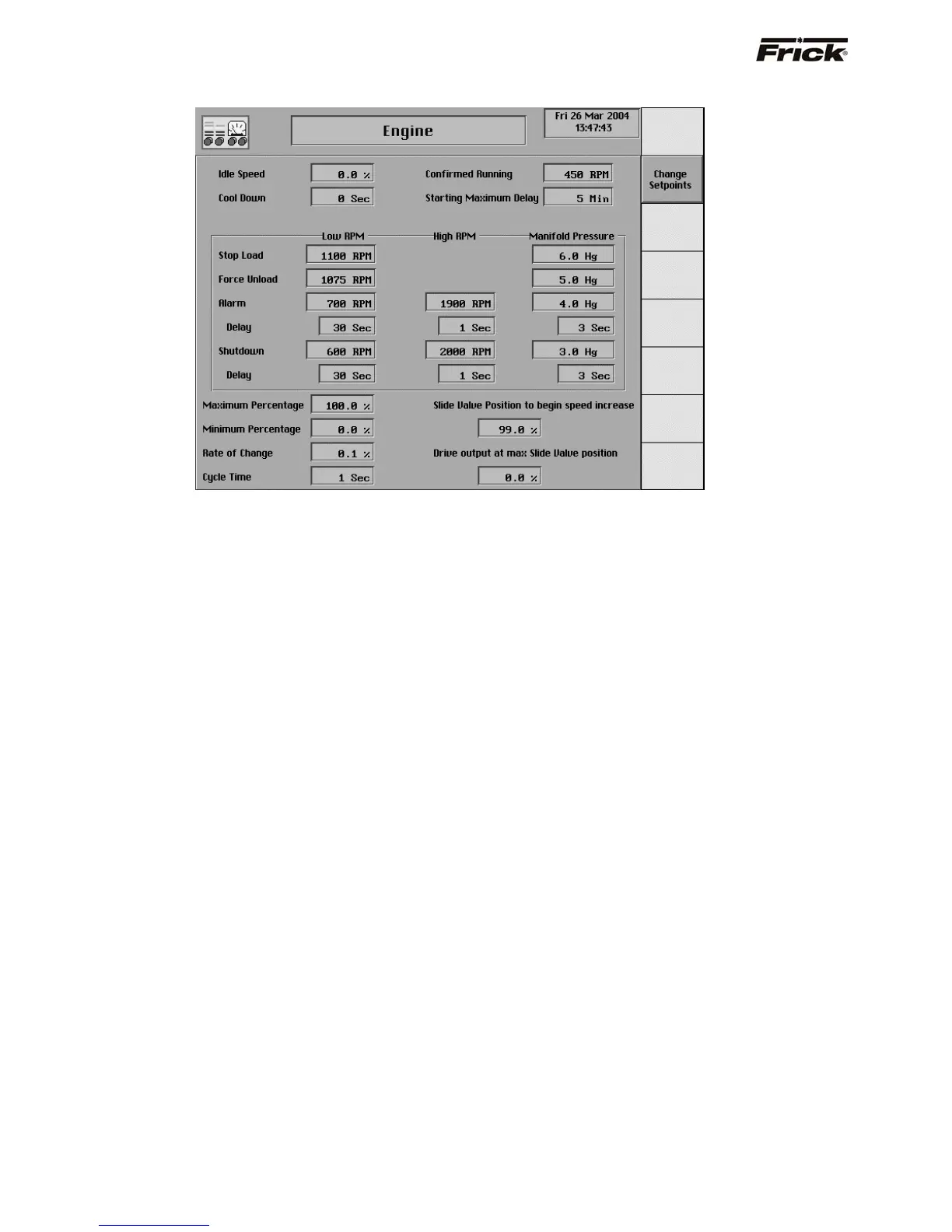

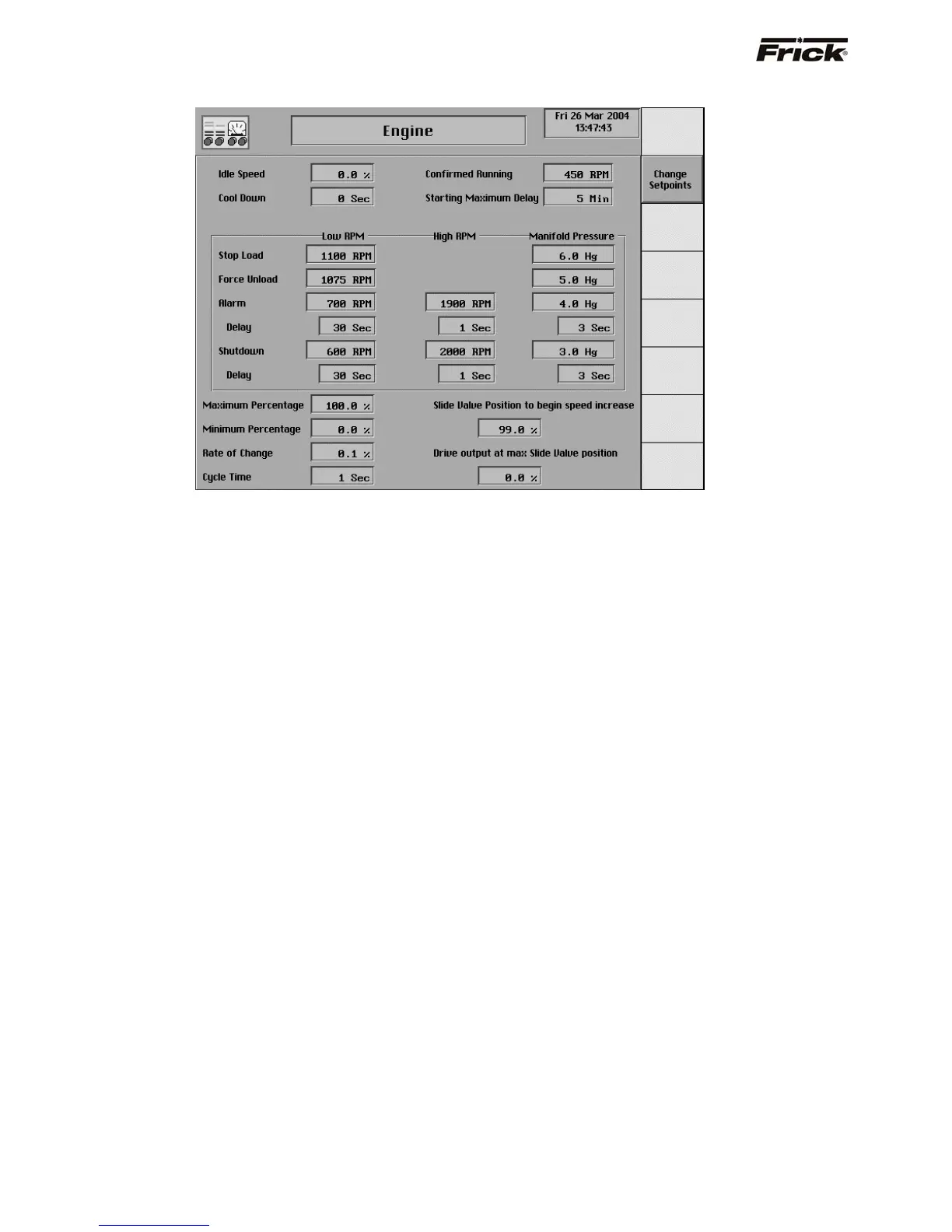

Engine

Hardware Signals

4 – 20 mA analog output – Signal from the

Quantum™ to provide the speed setpoint to the

speed governing device. The speed governing

device’s controller (i.e. Electronic Governor) and

hardware will need to be configured to the minimum

and maximum desired speed. The minimum speed

will vary depending on compressor type, consult the

factory application assistance.

4 – 20 mA analog input – Analog input channel on

the Quantum™ to monitor the actual RPM’s of the

drive. This signal can be sent to the Quantum™ from

the speed-governing device if available or generated

from a magnetic pickup located on the flywheel teeth

wired to a frequency to 4-20 mA converter.

Manifold Pressure (Engine only) – Pressure signal

required from the engine to detect and respond to

overload conditions.

Setpoints related to the Engine speed control output:

Idle Speed - If the Slide Valve is less than the

Highest Slide Valve Position to allow starting the

compressor setpoint, the Engine will be at idle.

Maximum output – Setpoint used to select the

maximum operating speed. Selectable from 1-100%

of the Quantum™’s 4-20 mA signal.

Minimum output – Setpoint used to select the

minimum operating speed. Selectable from 1-100% of

the Quantum™’s 4-20 mA signal.

Rate of change - Setpoint used to adjust the speed

changes sent to the VFD based on the capacity

control requirements. Selectable from .1-25% of the

4-20 mA signal.

Cycle Time – Setpoint used in conjunction with the

Rate of change setpoint to adjust the time between

speed changes sent to the VFD. Selectable from 1-30

seconds.

Slide Valve Position to begin Speed Increase –

The Slide Valve position which must be obtained

before the speed will begin to increase. Selectable

from 0-100% of the compressors Slide Valve position.

This setpoint is used in conjunction with the Drive

Output at Max SV position.

Drive Output at Max SV position – The desired

speed of the engine/turbine when the Slide Valve

position reaches 100%. This setpoint is selectable

from 1-100% of the Quantum™’s 4-20 mA signal and

is used in conjunction with the Slide Valve Position to

begin Speed Increase.

High RPM Alarm - If the RPM is greater than or

equal to this setpoint, for the alarm time delay, an

alarm occurs.

High RPM Shutdown - If the RPM is greater than or

equal to this setpoint, for the shutdown time delay, the

compressor will shut down.

High RPM Alarm Delay - The minimum time in

seconds that the RPM is greater than or equal to the

High RPM alarm setpoint before notification of the

alarm.

High RPM Shutdown Delay - The minimum time in

seconds that the RPM is greater than or equal to the

High RPM shutdown setpoint before the compressor

will shut down.

Low RPM Stop Load - If the RPM is less than or

equal to this setpoint, the compressor will be

prevented from further loading until the RPM is

greater than this setpoint. This setpoint helps avoid

forced unloading.

Low RPM Force Unload - If the RPM is less than or

equal to this setpoint, the compressor will be forced to

unload until the RPM is greater than this setpoint.

This setpoint helps avoid a low RPM alarm or

shutdown.

S90-010 O FRICK QUANTUM™ COMPRESSOR CONTROL PANEL

Page 28 OPERATION

Loading...

Loading...