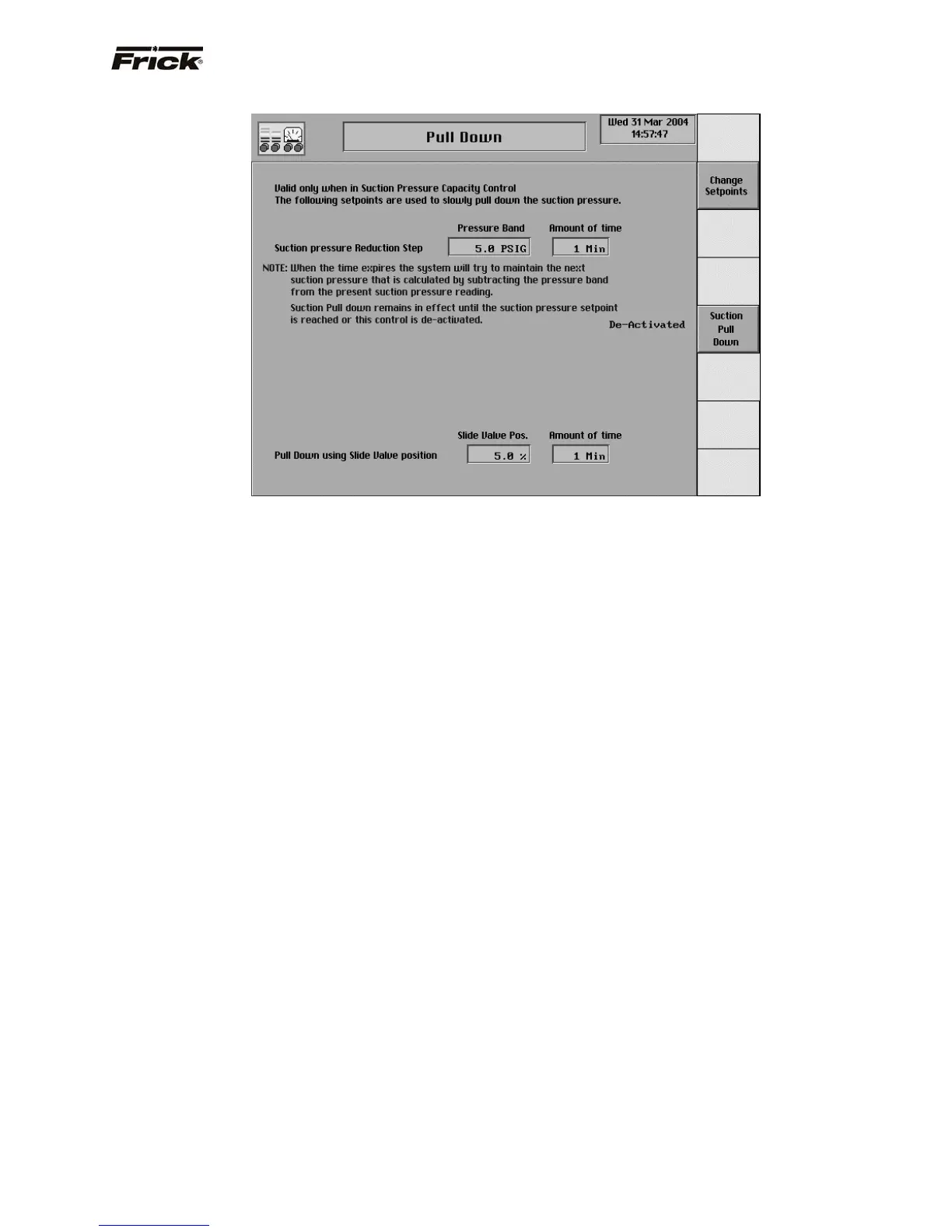

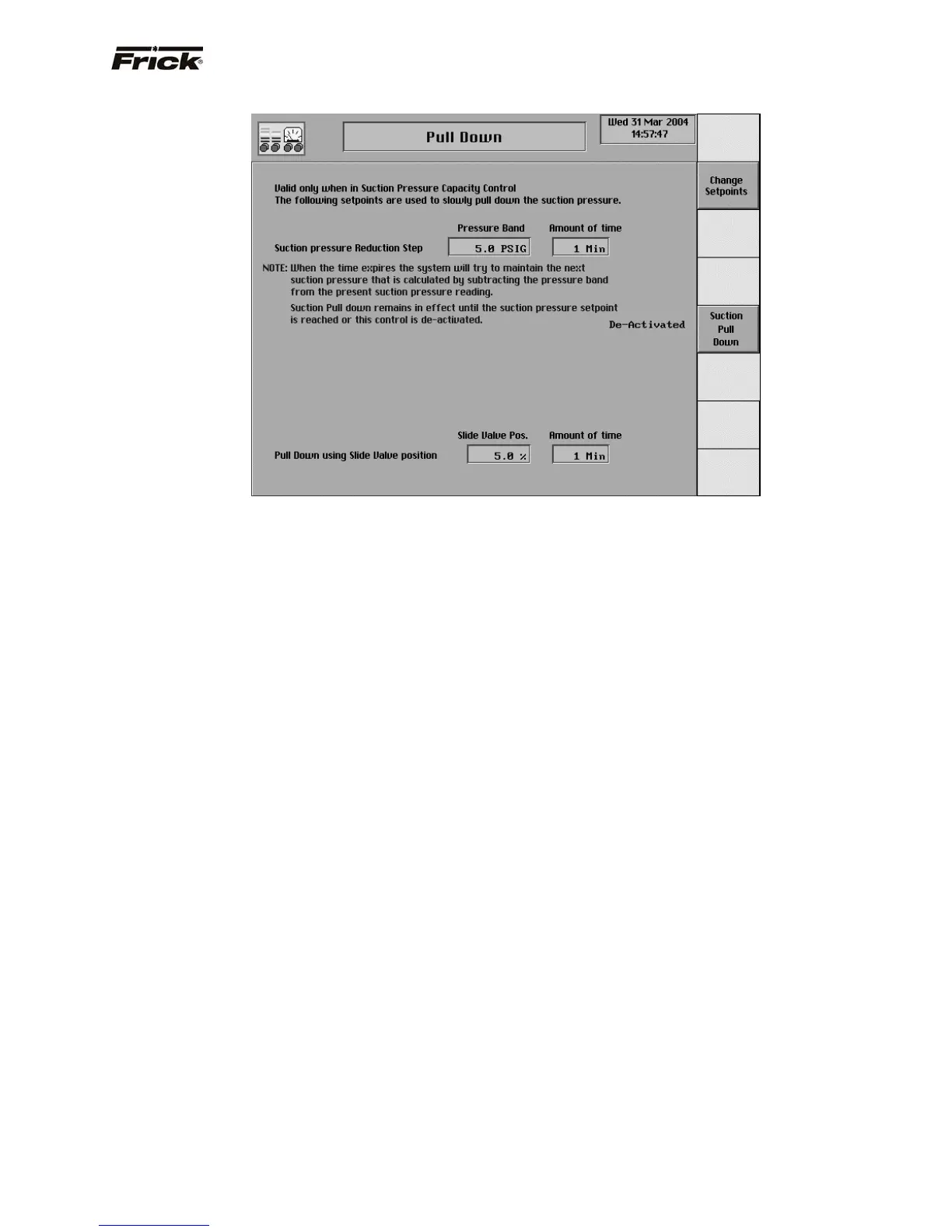

Pull Down

This screen is shown if the Pull Down option was selected

in Panel Setup. Pull Down is only valid when in Suction

Pressure Capacity Control. With this option enabled, the

Suction Pressure can be slowly lowered in steps from the

Starting Suction Pressure setpoint to the Suction Pressure

Capacity Control setpoint. Slowly walking the pressure

down prevents rapid drops in system pressure that causes

violent boiling of refrigerant in the system. When the

Suction Pull Down feature is activated and the compressor

is started, the Capacity Control setpoint is changed to the

current Suction Pressure. After the Amount of Time

setpoint has timed out the Capacity Control setpoint is

changed again. The Capacity Control setpoint is reduced

by the amount of the pressure band. The system steps

down to this setpoint and stays there until the time-out

period has again elapsed. Then the Capacity Control

setpoint is reduced again. The Capacity Control setpoint

changes regardless of whether the system is following it or

not. The Suction Pressure Pull Down feature is re-

activated every time the machine is started unless it is de-

activated.

This screen has the following setpoints:

Suction Pressure Reduction Step Pressure Band -

This is the amount of Suction Pressure that will be

used to step down the system. This value is

subtracted from the starting Suction Pressure to

provide a Capacity Control setpoint. The Capacity

Control setpoint continues to be calculated by

subtracting the pressure band from the previously

calculated Capacity Control setpoint until the Suction

Pressure reading reaches the operator entered

Capacity Control setpoint.

Suction pressure Reduction Step Amount of Time

– This is the time in minutes the Suction Pressure is

maintained at each step during Suction Pressure pull

down.

Pull Down using Slide Valve Position

• Slide Valve Position - The percentage of

travel that the Slide Valve is permitted to

load upon Compressor starting, and

thereafter determined by the Amount of Time

setpoint. For example, if this setpoint is 5%,

and the Amount of Time setpoint is 1 Minute,

then the Slide Valve will be permitted to load

5% of its stroke every minute, until such time

as the compressor has reached capacity. It

would take 20 minutes for the Slide Valve to

fully load to 100% at this rate. When the

Slide Valve is not moving, the following

message will be displayed on the Operating

Status screen Stop Load - Slide Valve

Pulldown: xx% where xx is the Slide Valve

Position percentage. Once capacity has

been achieved, this function is ignored, until

such time as the compressor is restarted.

• Amount of Time - The amount of time

between when the Slide Valve is permitted to

move. See Slide Valve Position description.

Note: It is recommended to use Suction Pull Down when

using Suction Pressure Mode 1 or 2, for best results, use

Slide Valve Pull Down.

FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 61

Loading...

Loading...