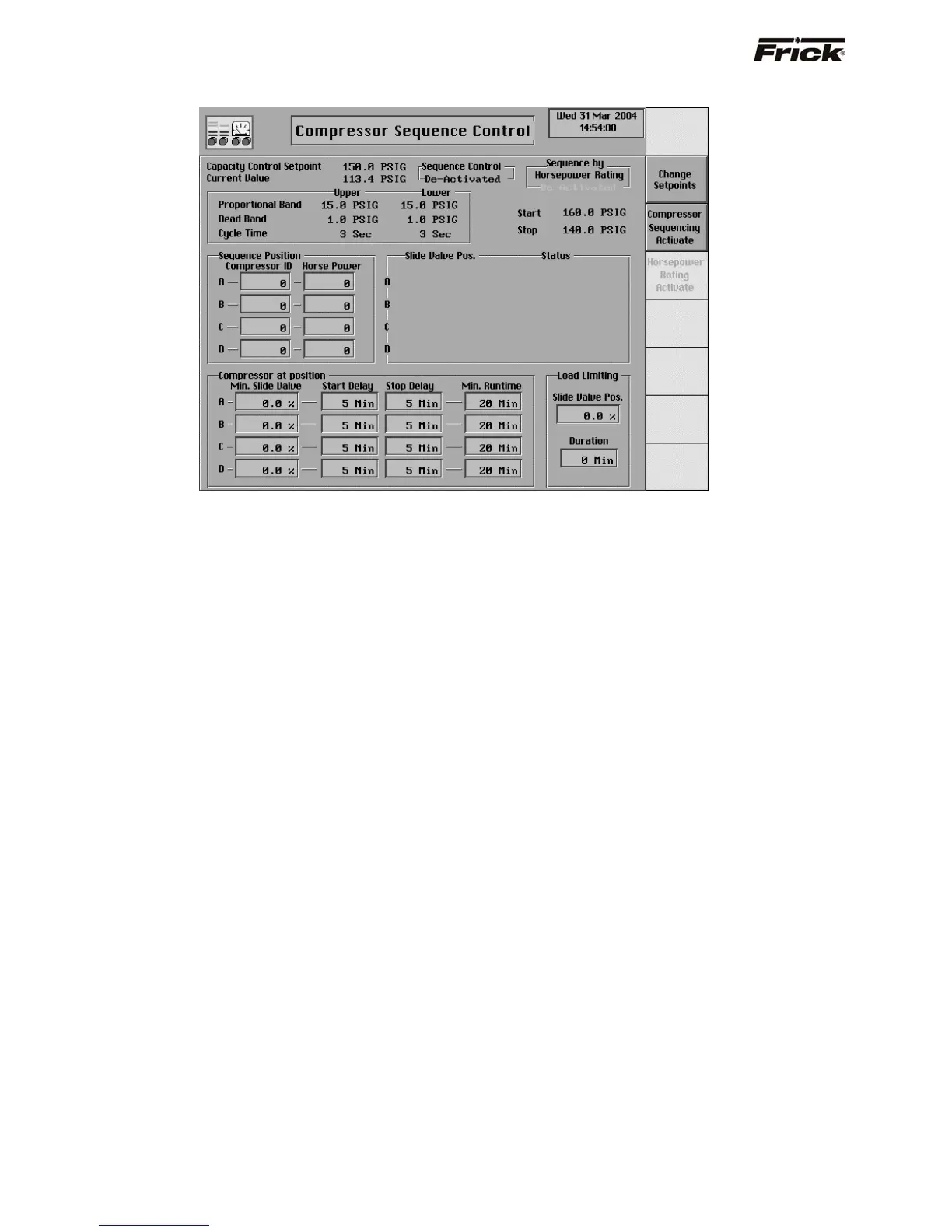

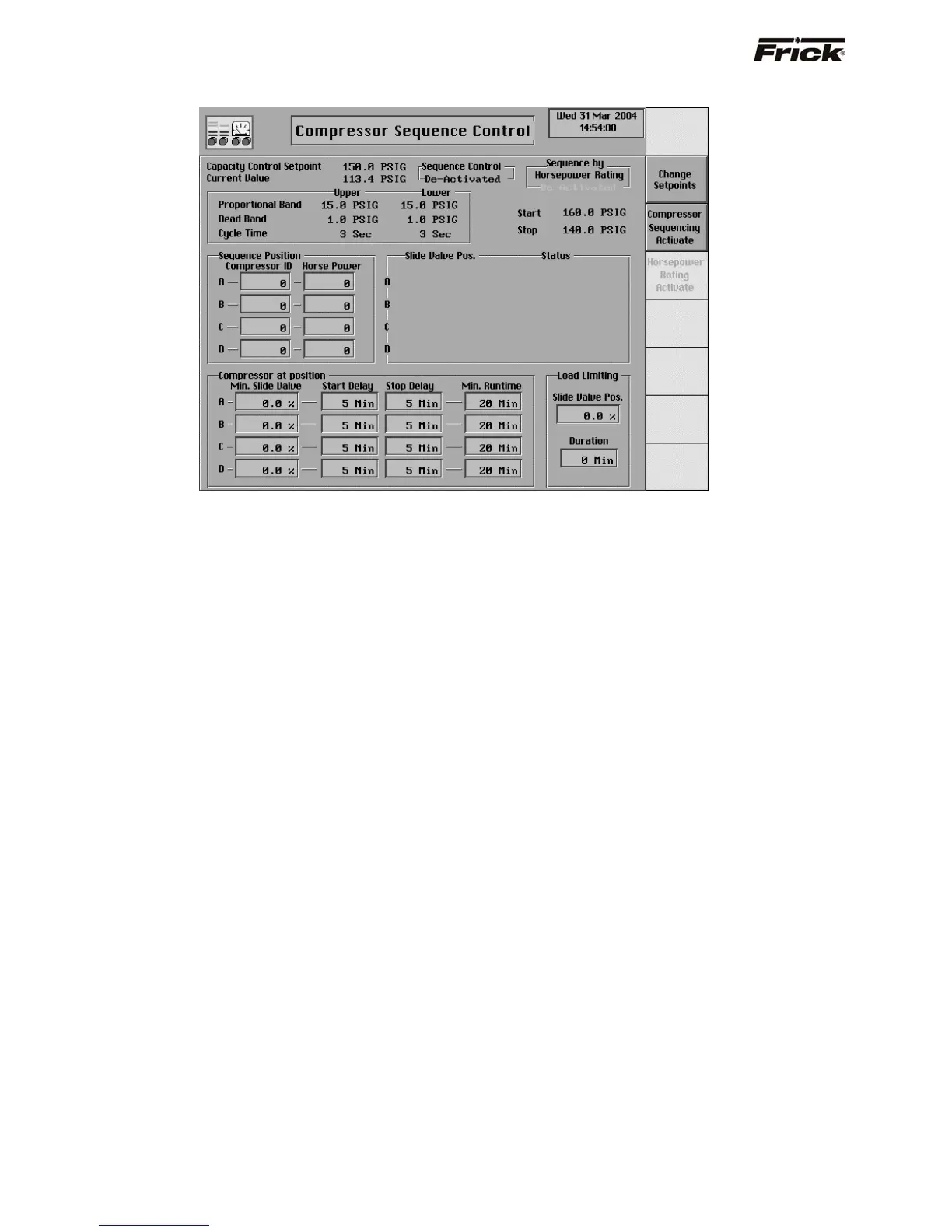

Compressor Sequence Control (MODE 1)

This screen is shown if the Sequence Mode 1

Compressor Sequencing option was selected in Panel

Setup. For quick access to this screen there is a

[Compressor Sequence Setpoints] screen key on the

Operating Status -2 screen. This sequencing is intended

for compressors that are operating to maintain the same

Capacity Control setpoint. The settings on this screen are

used to sequence the compressors when a compressor is

in the remote start mode of operation and in remote Slide

Valve mode and available to run i.e. not in shutdown

(cutout) or Recycle Delay. This sequence control is only

used for compressors with a variable Slide Valve and will

work with existing Frick RWB, RXB, and RXF panels.

Serial communication using the Com-1 port is used for this

sequencing (drawing nos. 640A0042 and 640A0050.

The setpoints that are currently being used for Capacity

Control are only shown here for referencing. These

setpoints are taken from the active Capacity Control

settings at the panel where Compressor Sequencing is

activated. Current Value is the current reading or actual

reading of the pressure or temperature process variable

that was chosen as the Capacity Control method.

Compressor Sequencing can be enabled from panel setup

and entered on more than one panel. However; for proper

control, only the Compressor Sequencing settings at one

panel should be made active. The following describes how

Compressor Sequencing uses the Capacity Control

setpoints:

Capacity Control - This is the reading that the control

sequence will attempt to maintain for the indicated

process. This setpoint is used to control the loading

and unloading of the compressors.

The Proportional Band setpoint determines a range of

Capacity Control values where proportionally timed

pulsed output is used. Beyond the proportional band

the output is continuously energized. The length of

time the output will be pulsed on is proportional to the

distance the current reading of the process variable is

from the Capacity Control setpoint. The further the

distance from setpoint, the longer the output is pulsed

on and the shorter the output is off. The closer the

distance to setpoint, the shorter the output is pulsed

on and the longer the output is off. If the actual

reading is midway from setpoint, the output is on and

off an equal amount of time. (See Cycle Time).

Upper Proportional Band - A band, measured

in the units of the Capacity Control setpoint,

above the upper dead band, where proportional

load control is used. If the actual reading rises

into this proportional band, the load output will be

pulsed as explained above in the description

about proportional band.

Lower Proportional - A band, measured in the

units of the Capacity Control setpoint, below the

lower dead band, where proportional unload

control is used. If the actual reading falls into this

proportional band, the unload output will be

pulsed as explained above in the description

about proportional band.

Upper Dead Band - A band, measured in the

units of the Capacity Control setpoint, above the

setpoint at which the compressor will neither load

nor unload.

Lower Dead Band - A band, measured in the

units of the Capacity Control setpoint, below the

setpoint at which the compressor will neither load

nor unload.

S90-010 O FRICK QUANTUM™ COMPRESSOR CONTROL PANEL

Page 50 OPERATION

Loading...

Loading...