• Capacity Up (Output 2) - This output is

energized to signal the next panel to load the

compressor.

• Capacity Down (Output 3) - This output is

energized to signal the next panel to unload

the compressor.

• Slide Valve > Minimum (Output 8) - This

output is energized to signal the previous

panel that the Slave’s slide valve reading is

above the Minimum Capacity when Running

setpoint.

Input Status (Digital Board 2):

• Start (Input 5) - This input is energized to

signal this panel to start the compressor.

This input is de-energized to signal this

panel to stop the compressor.

• Capacity Up (Input 6) - This input is

energized to signal this panel to load the

compressor.

• Capacity Down (Input 7) - This input is

energized to signal this panel to unload the

compressor.

• Slide Valve > Minimum (Input 4) - This

input is energized to signal this panel that

the Slide Valve reading of the next

compressor is above that panel’s Minimum

Capacity when Running setpoint.

The active capacity control setpoints are shown here for

referencing. The active Capacity Control setpoints are

taken from the Capacity Control settings at this panel.

Actual is the current reading of the pressure or

temperature that was chosen as the Capacity Control

setpoint. For proper control, only one panel should be

selected as the Master for compressor sequencing. The

Master compressor sequence controller attempts to

maintain the Capacity Control setpoint by loading and

unloading in response to the following capacity control

setpoints. The Slave compressor sequence controller is

signaled from a previous panel to load or unload and then

uses the following Capacity Control setpoints to determine

when to pulse the panel’s local Slide Valve load and Slide

Valve unload outputs. The signal for loading or unloading

from the previous panel overrides the Slave’s Capacity

Control settings that might be determining the opposite

local Capacity Control. For example, the Slave’s local

settings could indicate it should be loading but a signal

from a previous panel could be telling it to unload. In this

situation, the Slave will unload but it will pulse according to

its local settings. The Slave’s local settings are used to

determine pulse loading or unloading and if these settings

don’t coincide with the Master’s settings, then improper

pulsing can result. For good Capacity Control, it is

important that each panel is properly setup. The following

describes the compressor sequencing Capacity Control

setpoints:

Capacity Control - This is the reading which the

Master compressor sequence controller will attempt to

maintain. This setpoint at each panel is used to

control the loading and unloading of the compressor.

The Proportional Band setpoint determines a range of

capacity control values where pulsed output is used.

Beyond the proportional band the output is continuously

energized. The length of time the output will be pulsed on

is proportional to the distance the actual reading is from

the Capacity Control setpoint. The further the distance

from setpoint, the longer the output is pulsed on and the

shorter the output is off. The closer the distance to

setpoint, the shorter the output is pulsed on and the longer

the output is off. If the actual reading is midpoint from

setpoint, the output is on and off an equal amount of time.

Upper Proportional Band - A band, measured in the

units of the Capacity Control setpoint, above the

upper dead band, where proportional load control is

used. If the actual reading rises into this proportional

band, the load output will be pulsed as explained

above in the description about proportional band.

When in this band the Master compressor sequence

controller will begin the process of starting the

compressor.

Lower Proportional Band - A band, measured in the

units of the Capacity Control setpoint, below the lower

dead band, where proportional unload control is used.

If the actual reading falls into this proportional band,

the unload output will be pulsed as explained above in

the description about proportional band.

Upper Dead Band - A band, measured in the units of

the Capacity Control setpoint, above the setpoint at

which the compressor will neither load nor unload.

Lower Dead Band - A band, measured in the units of

the Capacity Control setpoint, below the setpoint at

which the compressor will neither load nor unload.

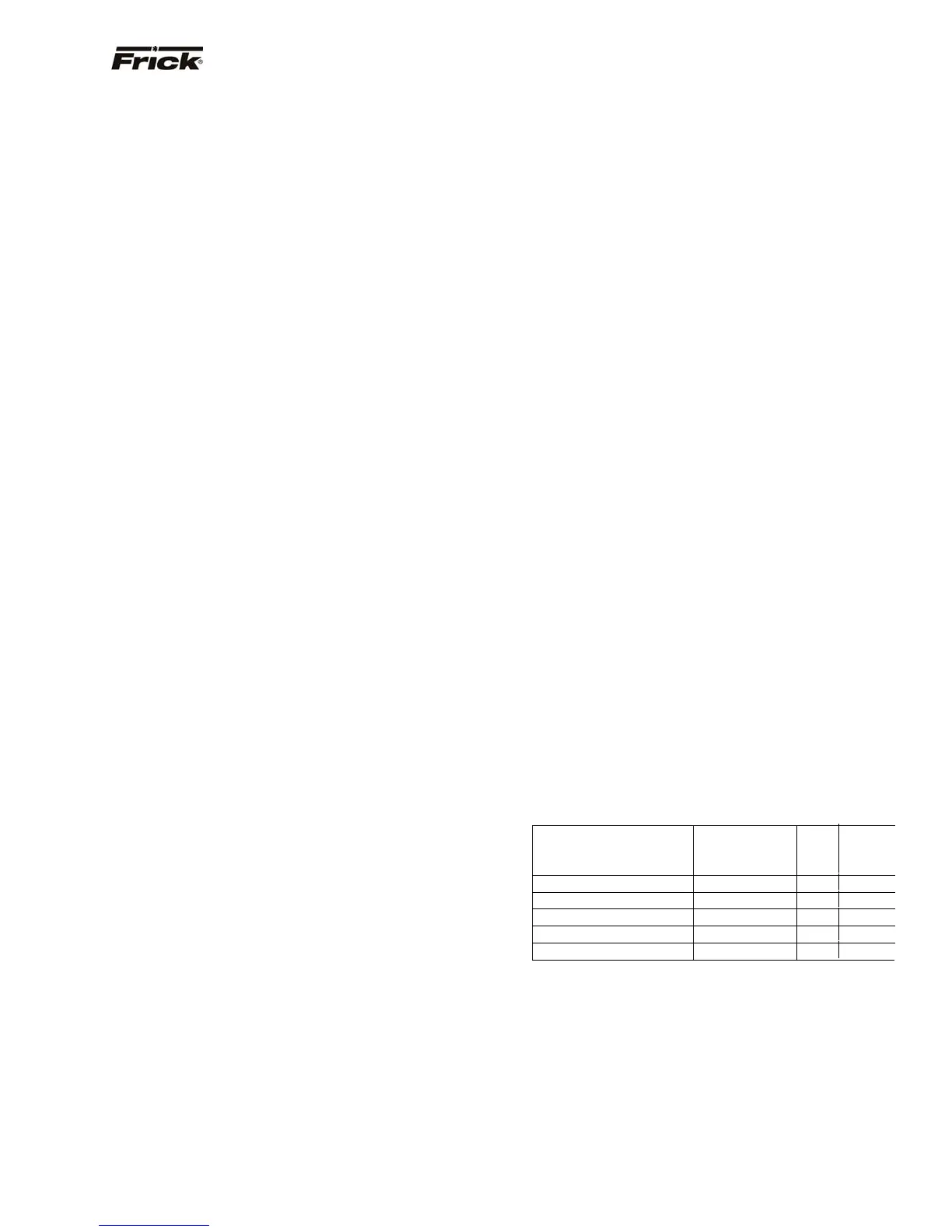

The Cycle Time setpoint determines the amount of time

the output is on and off, when in the proportional band. At

the completion of the cycle time the actual reading and

necessary response is re-evaluated. If a 4 second period

is selected, then the following will result:

Proportional Distance

Actual Reading is

From Setpoint

Output

Pulsed On

(seconds)

Output Off

(seconds)

0 0 4

1/4 1 3

1/2 2 2

3/4 3 1

1 4 0

Upper Cycle Time - This setpoint determines the

amount of time in seconds that the load output is on

and off, when in the upper proportional band. Refer to

the above description about cycle time.

Lower Cycle Time - This setpoint determines the

amount of time in seconds that the unload output is

on and off, when in the lower proportional band. Refer

to the above description about cycle time.

FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL S90-010 O

OPERATION Page 55

Loading...

Loading...