S90-010 O FRICK

QUANTUM™ COMPRESSOR CONTROL PANEL

Page 92 OPERATION

• (Module 6) - Remote Unload or Remote C.C

step 2 for step units

• Remote Unload - If the Slide Valve is in

remote and this input is energized, the Slide

Valve unload solenoid will be energized.

• Remote C.C step 2 for step units - If the

Capacity Mode is in Remote this input is

used to step on and off capacity according to

the Remote Capacity Control chart.

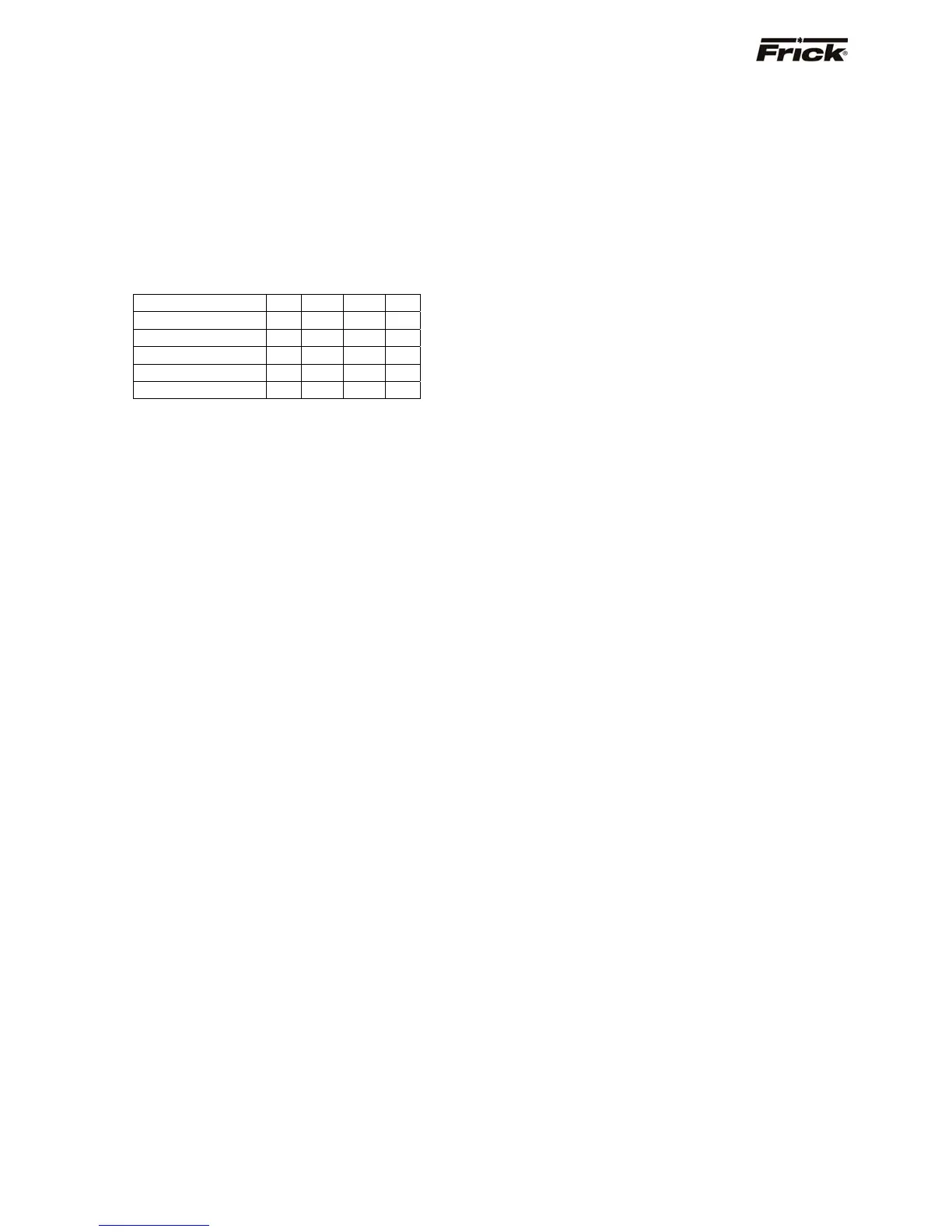

Remote Capacity Control Chart

Input \ %Capacity 25 50 75 100

3-Step Input 4

OFF OFF ON

3-Step Input 5

OFF ON ON

4-Step Input 4

OFF ON OFF ON

4-Step Input 5

OFF OFF ON ON

• Recycle Delay (If compressor is off) - This

output is energized while the remaining time

in minutes for Recycle Delay is greater than

zero (0). Recycle delay time is the time that

must elapse prior to allowing the compressor

to restart. This timer times out while the

compressor is running or stopped since the

Recycle Delay is a start-to-start protection.

The Recycle Delay time is intended to

prevent damage to the motor from

successive restarts. For further setup see

the Motor Control Setpoints screen

• Sequence Input (If compressor is on) –

Reports the status of Stop Load or Force

Unload (See Slide Valve and Slide Stop

Status box for further details).

The Hot Gas Bypass/SV Setpoint option can be used.

This option, which is enabled in Panel Setup, is not

available for all compressor models (Reference

Compressor Model Differences). Three digital outputs are

provided that signal when the Slide Valve has reached

preset positions. For further setup, see the Slide Valve

Setpoints screen.

The Remote Control Setpoint option can be used. This

option, which is enabled in Panel Setup, is not available

for all compressor models (Reference Compressor Model

Differences). This uses the Remote Control Setpoint

analog input and the Remote Control Setpoint analog

output for Capacity Control of compressors. For further

setup see the Calibrate Remote Control Setpoint screen

and the [Remote Setpoint] command key from the Slide

Valve Mode screen command keys on the Operating

Status screen.

The Remote Slide Valve Position option can be used. This

option which is enabled in Panel Setup is not available for

all compressor models (Reference Compressor Model

Differences). This uses a (4-20 ma) input signal to the

Remote Slide Valve Position analog input (Channel #13

on Analog Board #1) to control the Slide Valve. For further

setup see the Calibrate Slide Valve Position screen and

the [Remote Slide Valve] command key from the Slide

Valve Mode screen command keys on the Operating

Status screen.

The Slide Valve Position \ Capacity analog output can be

used to determine the present Slide Valve position % or

Capacity % dependent on the compressor model

(Reference Compressor Model Differences). A (4-20 ma)

output signal to the Slide Valve Position \ Capacity analog

output (Channel #3 on Analog Board #1) corresponds to

the present (%) value displayed on the Operating Status

screen.

ASCII communication to the Com-2 port can be used

(reference S90-010 CS Communications Setup manual).

A compressor should be in both Remote Compressor

Mode and Remote Slide Valve or Capacity Mode for

Remote Control.

Note 1: If the compressor is in Remote mode and

communication through the communication port has

not occurred for 5 minutes, then the compressor is

placed into Automatic mode and the Slide Valve is

placed into Auto mode.

Note 2: If there is a shutdown in response to a safety

setting, a compressor in Remote mode is placed into

Manual mode requiring operator intervention.

Loading...

Loading...