ArcGlide THC Instruction Manual 4-7

MAINTENANCE

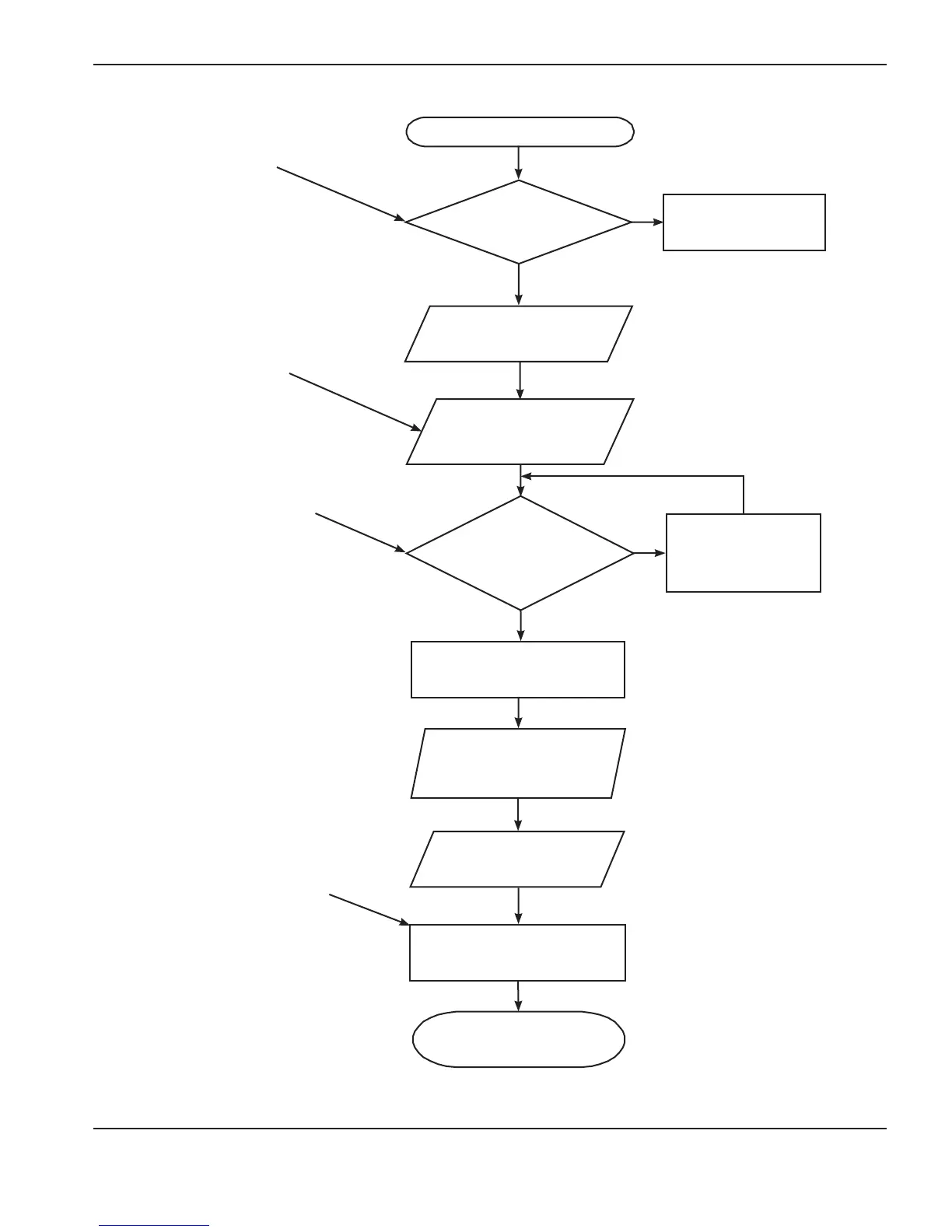

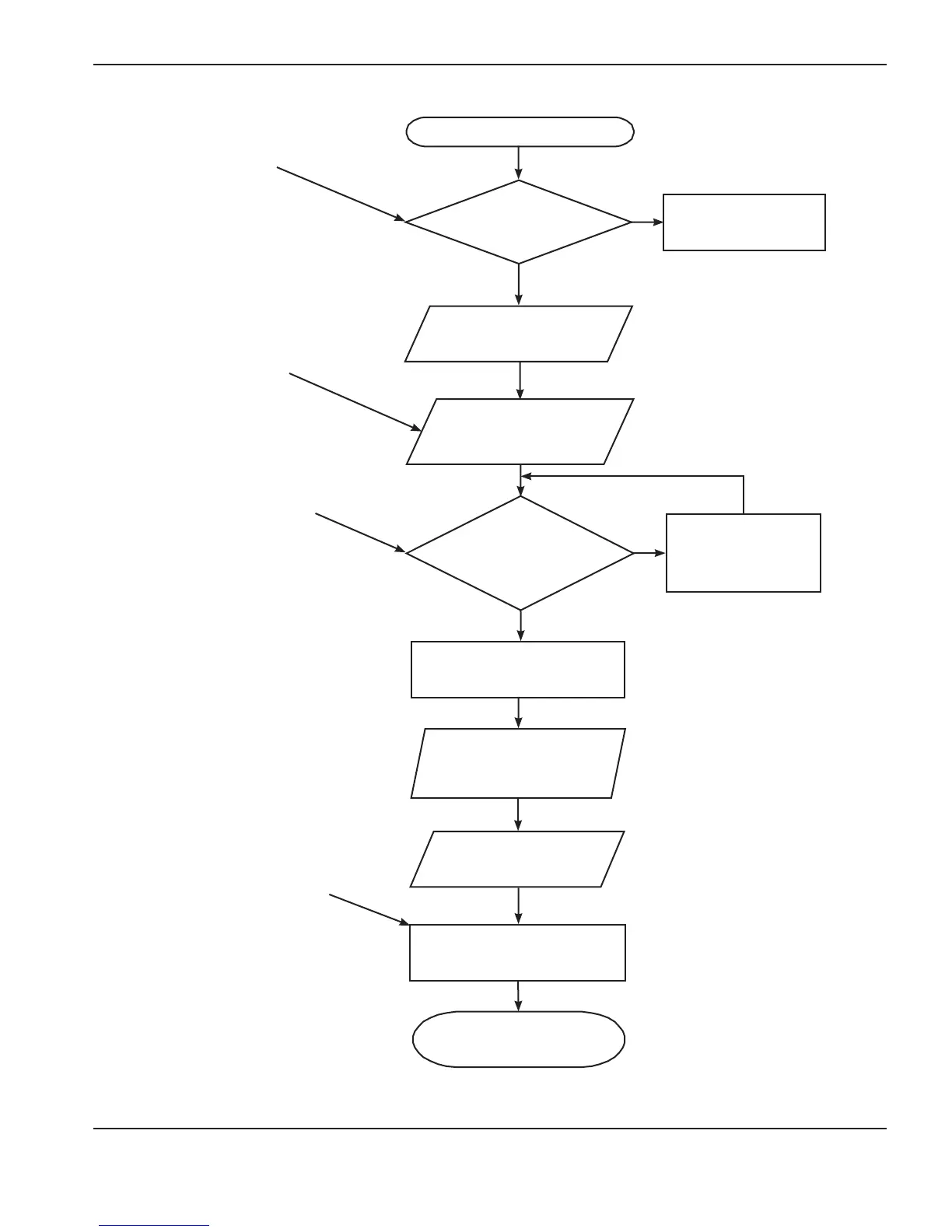

Flow of ArcGlide operations (continued)

The Spare input activates

when the test fixture cables

are connected.

Data is automatically copied

into the operating parameters

and the status is automatically

transmitted.

I/O is updated and control loops

execute at 10 mSec intervals.

Excess time in this loop is spent

servicing the RS422 connection.

Critical errors must be corrected before

power is turned on again.

• Encoder overow or underow

• Field supply failure

• Interlock activated

• Lifter breakaway activated

• AC voltage low or high

• Max processor temperature

• Motor drive fail

• No Hypernet link

• Lost previously linked HMI or CNC

Main loop

Write expansion

outputs.

Service active Hypernet links.

Service watchdog timer.

Service analog I/O.

Read arc voltage.

Write motor current.

Read expansion inputs.

Check for critical errors.

Operating states

CNC

Spare2_in?

Self-diagnostics

10 mSec interval?

Service RS-422 and check

tip-touch.

no

yes

yes

no

Loading...

Loading...