Plasma Power Supply

44 809970 Field Service Bulletin XPR300

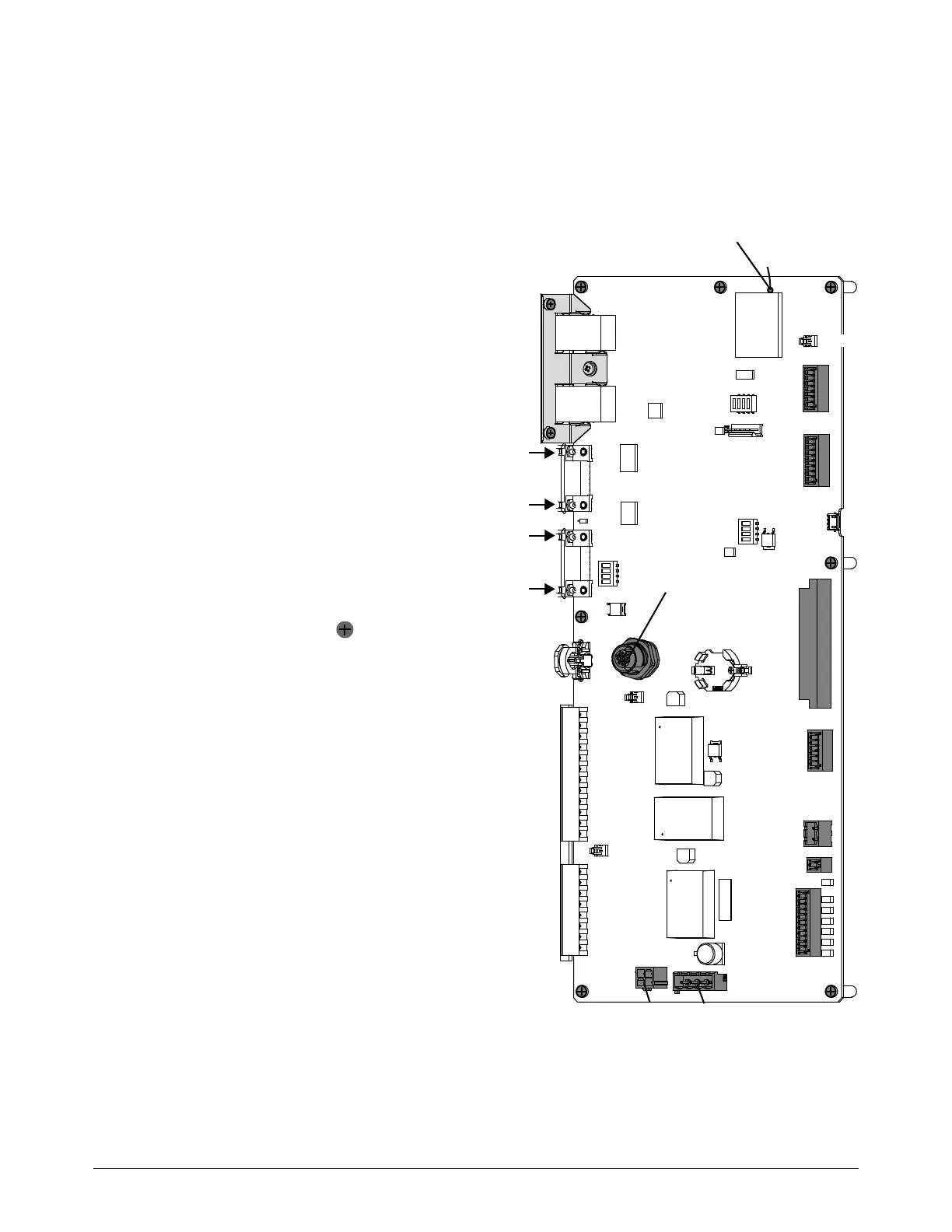

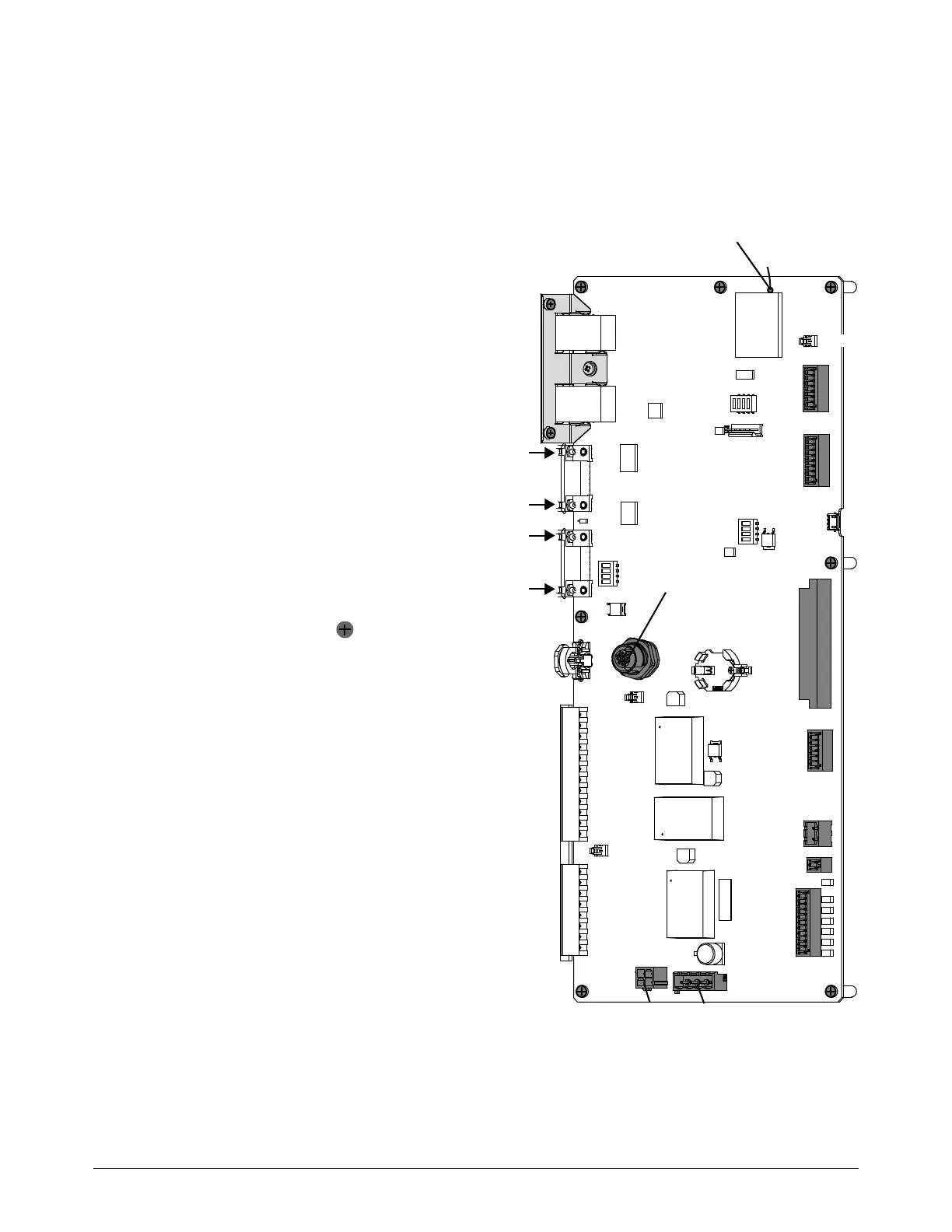

Replace the control PCB

See Control side – view 2 on page 127 for location and part number.

1. Complete the following procedures:

a. Remove the power from the cutting

system.

b. See Remove the left-side

(control-side) panel on page 61.

c. See Remove the rear panel on

page 62.

Keep all nuts and screws that

you remove.

2. Disconnect the communication interface

cables. (discrete, serial, or EtherCAT)

3. Disconnect all of the wire connectors.

4. Use a 3/16 inch, hexagonal-socket

wrench to remove the 4 nuts from the

serial RS-422 connectors.

5. Remove the 9 screws.

6. Move the PCB to the right to release the

PCB from the external CAN connector.

7. Use the screws to install the new PCB.

8. Use a 3/16 inch, hexagonal-socket

wrench to install nuts on the serial

RS-422 connectors on the rear panel

side.

9. Make sure that J21 is in the OFF

position.

10. Connect all of the wire connectors.

11 . Connect the communication interface

cables.

Make sure that you connect the

in and out cables to the correct

locations.

J4

Out

J7

J8

J23

J16

J6

J1J5

Wireless antenna

CAN

In

J2

J21

Loading...

Loading...