Gas Connect Consoles

80 809970 Field Service Bulletin XPR300

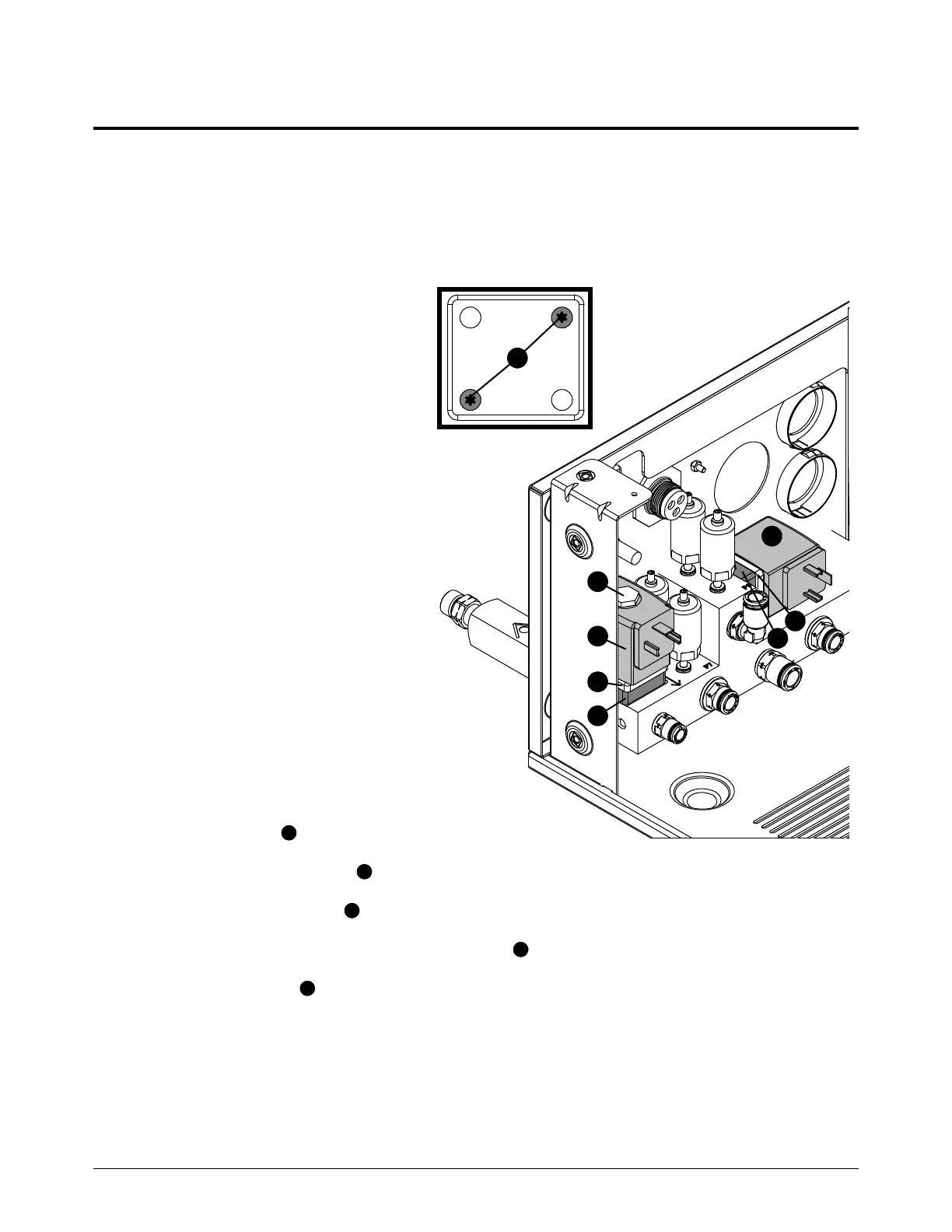

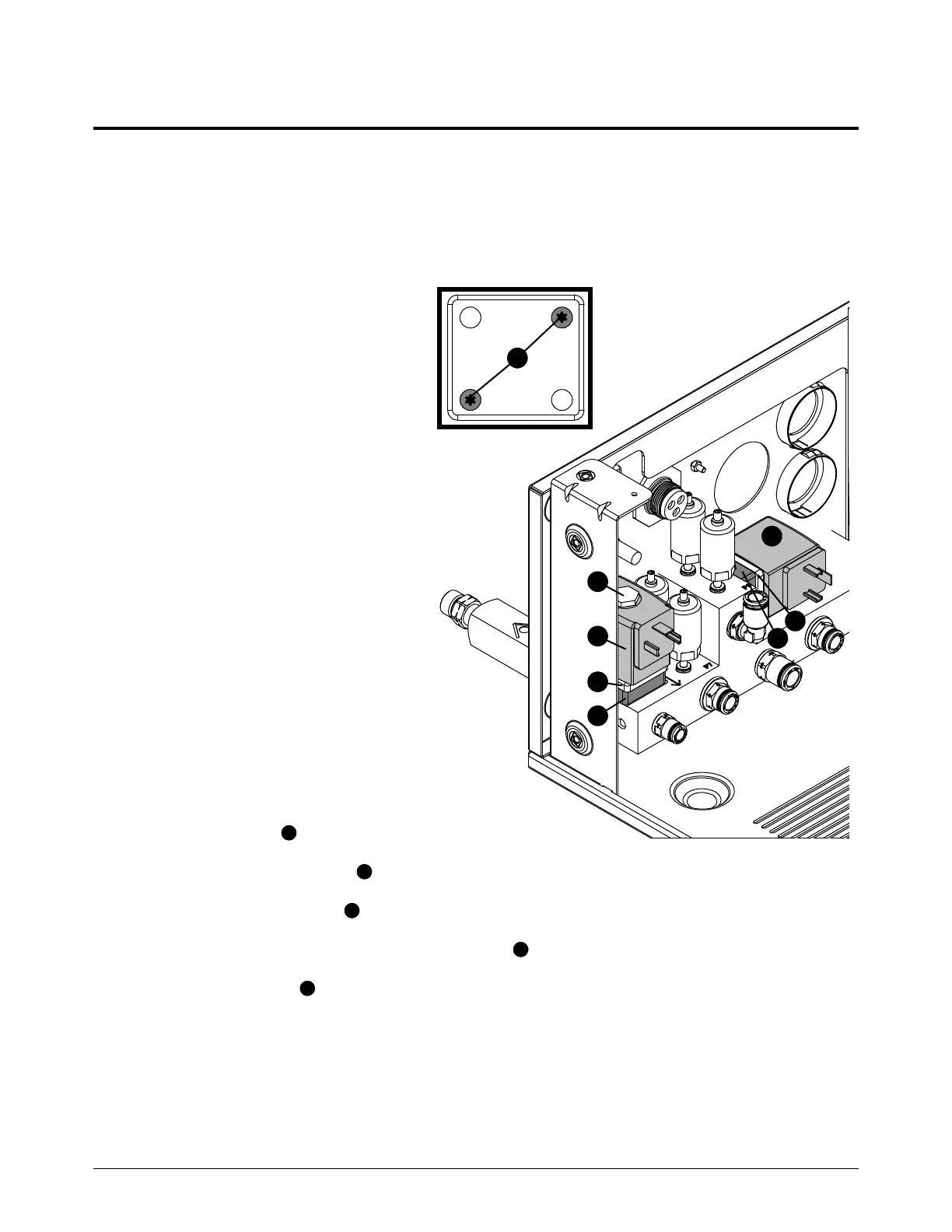

Replace a proportional valve

See VWI and OptiMix gas connect console mixer, transducers, and

valves on page 138 for location and part number.

Remove a proportional valve

1. Complete the following

procedures:

a. Remove the power from the

cutting system.

b. Remove the gas and fluid

pressure from the cutting

system.

c. Remove the top panel.

d. Remove the manifold-side

panel.

See Gas connect

console panels on

page 87.

Keep all nuts and screws

that you remove.

2. Remove the screw from

connector (not shown).

3. Remove the connector (not

shown).

4. Use a 14 mm socket wrench to

remove the nut .

5. Remove the coil/solenoid .

6. Remove the base cover .

7. Use a T20 screwdriver to remove the 2 screws .

8. Remove the base .

Loading...

Loading...