2 - TECHNICAL INFORMATION SMART320

EN

2 - Pag. 3 / 20

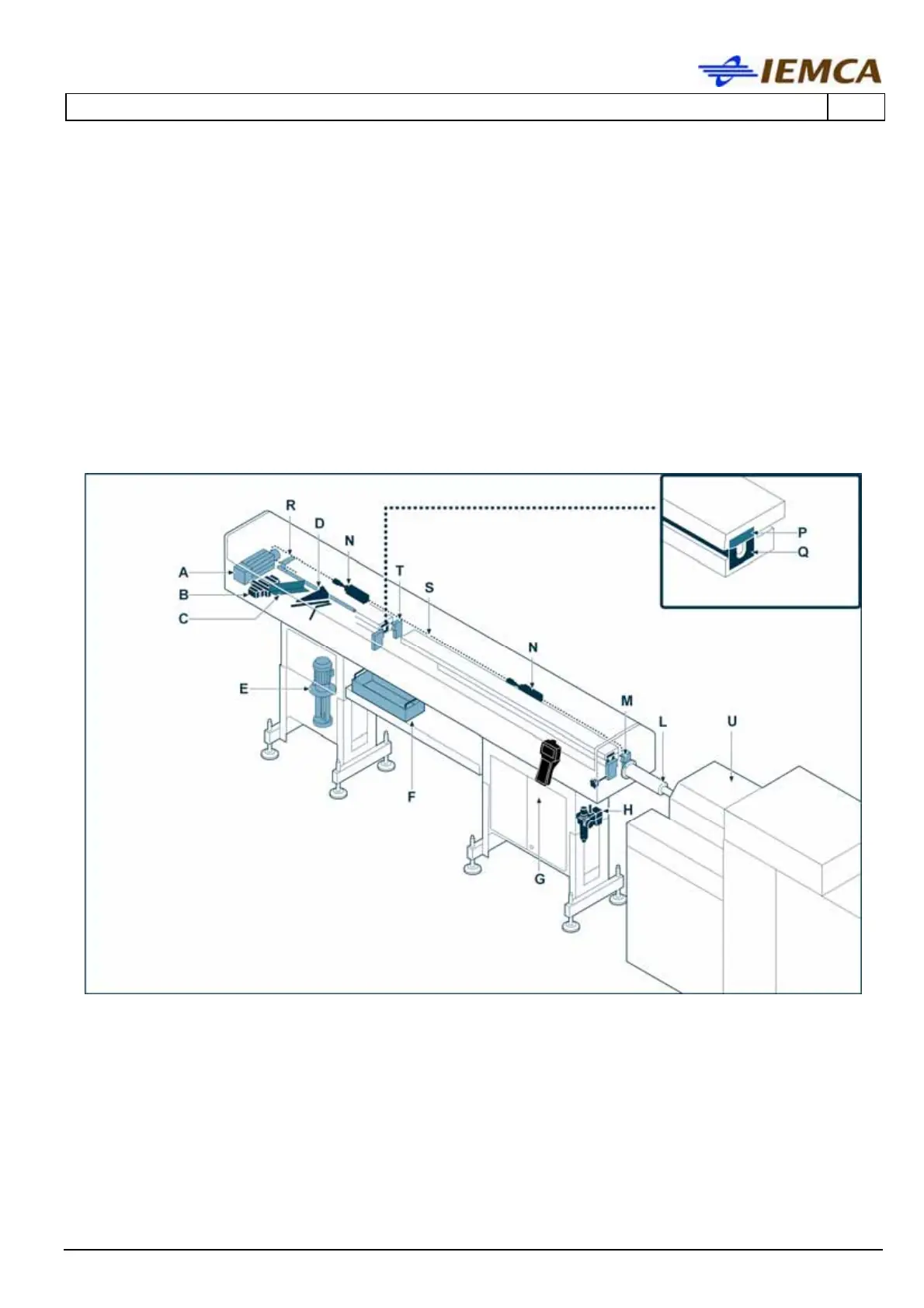

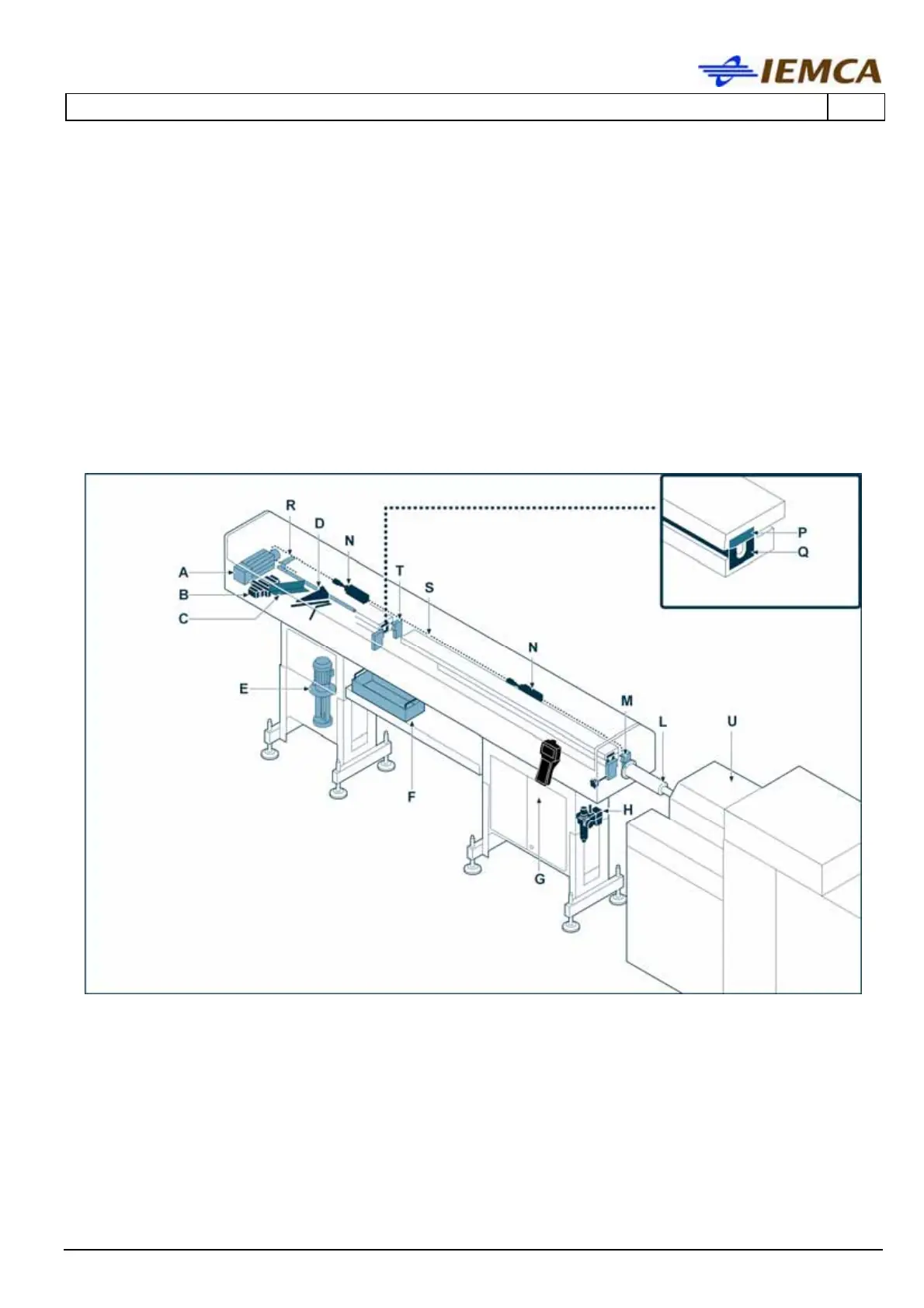

B SOLENOID VALVE UNIT; sends signals to the pneumatic components.

C BAR POSITIONING DEVICE; allows finding the bar aligning position on the magazine rack.

D MAGAZINE; stores the bars.

E LUBRICATION PUMP; delivers oil to the guide channels.

F REMNANT RECOVERY BOX; bar remnants are dropped into this box after extraction from the

bar pusher collet.

G KEYBOARD; it allows bar feeder programming and function actuation.

H PRESSURE REGULATOR; to adjust the pressure of the pneumatic devices.

L TELESCOPIC NOSE; allows bar guidance between the bar feeder and the headstock.

M HALF-BUSHING DEVICE, holds the bar centred.

N PNEUMATIC CYLINDER FOR GUIDE CHANNEL OPENING/CLOSING; provides motion to the

pneumatic devices to allow opening/closing the guide channels.

P UPPER GUIDE CHANNELS; drive the bar during the machining.

Q LOWER GUIDE CHANNELS; drive the bar during the machining.

R BAR PUSHER; pushes the bar during the machining.

S FEEDING CHAIN; transmits the motion from the motor to the bar pusher.

T CLAMPS; hold the bar during the loading and removal from the collet of the bar pusher.

U LATHE.

Loading...

Loading...