4 - HANDLING AND INSTALLATION SMART320

EN

4 - Pag. 15 / 26

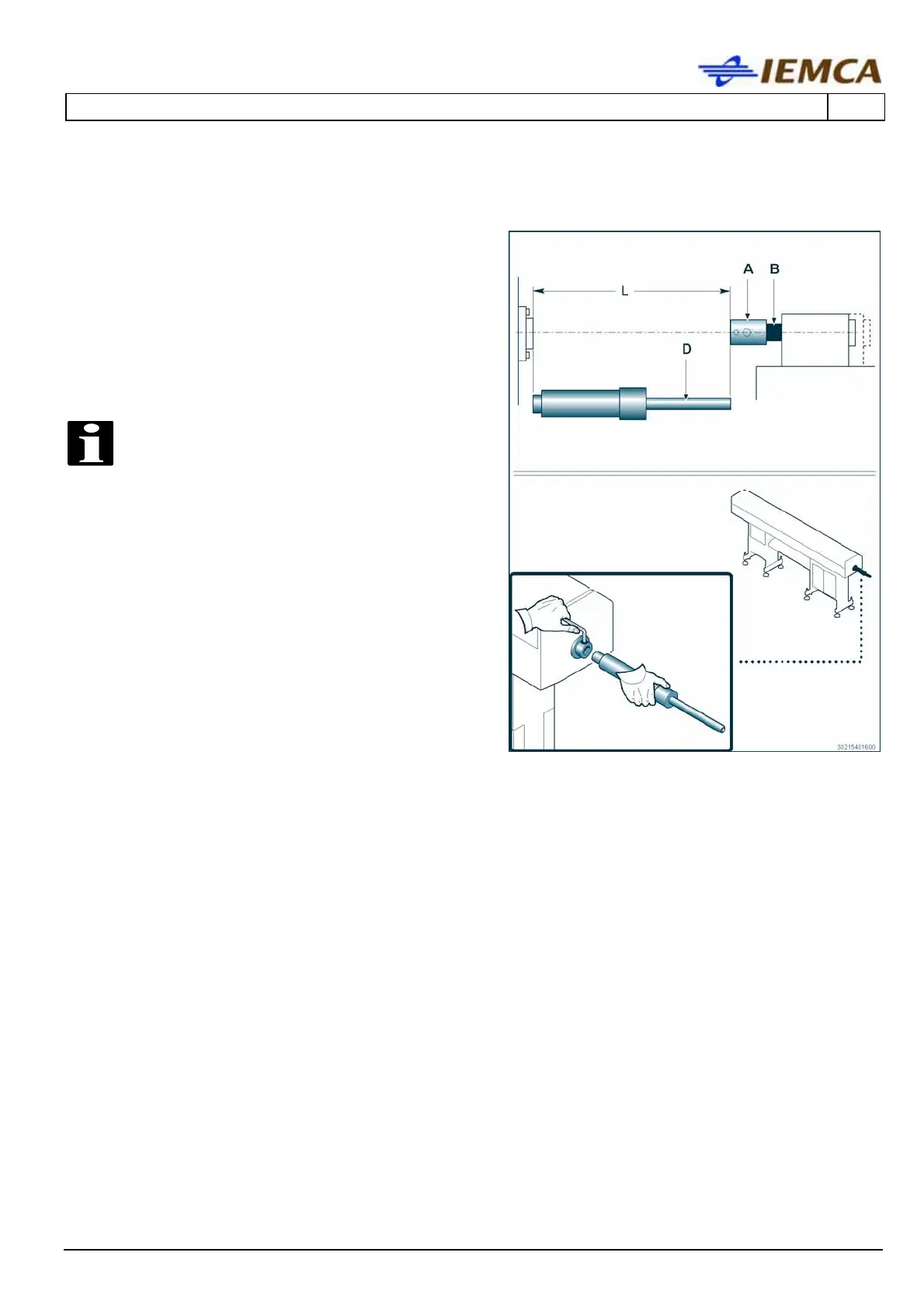

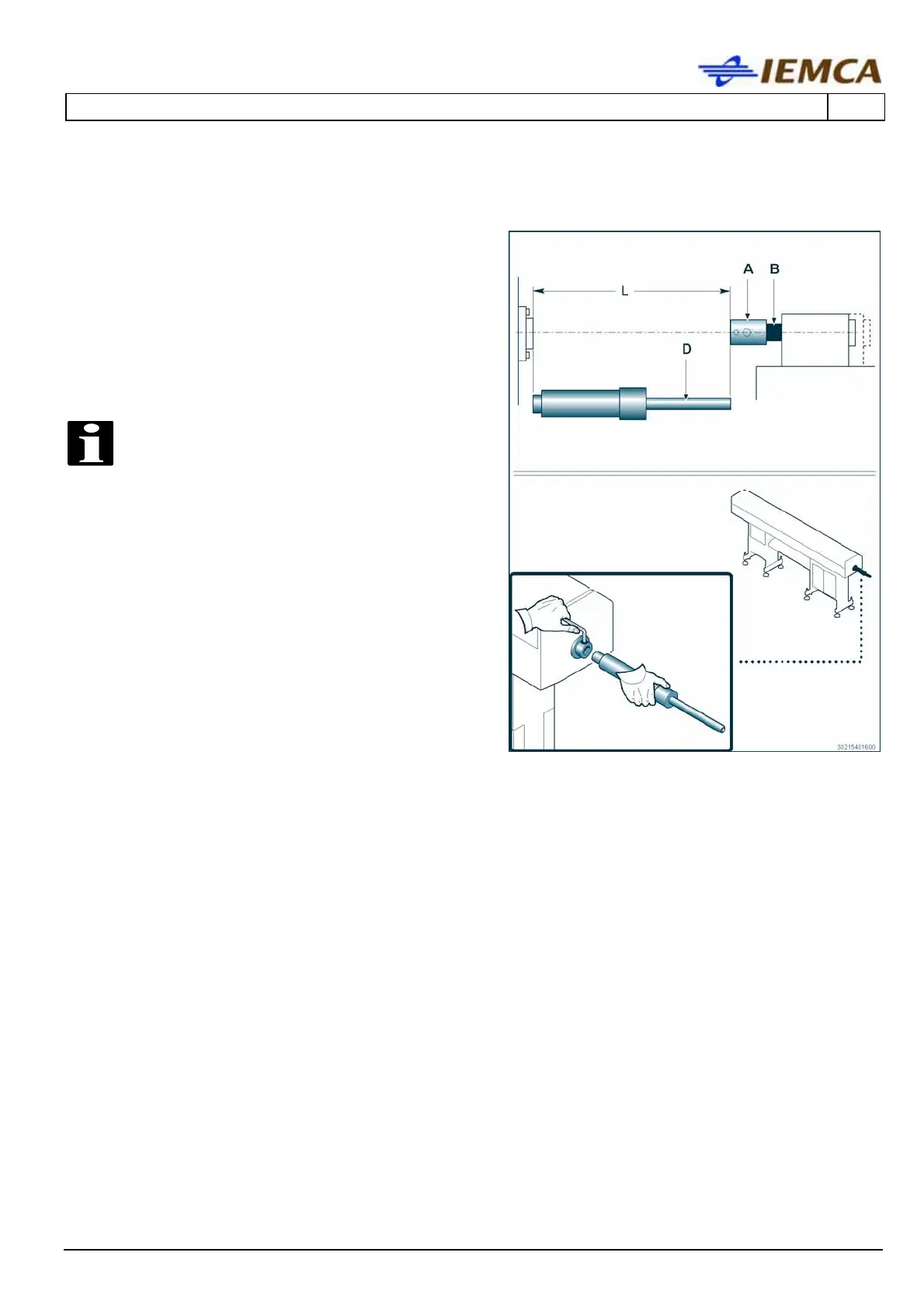

4.5.2 Telescopic nose - Installation

If the feeder is equipped with a telescopic nose,

proceed as described below.

• Remove the fixed sleeve that had been installed

to obtain alignment between the feeder and the

lathe.

• Fix the flange (A) (a general example is shown

in the figure).

INFORMATION:

the lathe spindle nose (B) should not

turn. If it does, a bearing or another

similar device should be mounted to

prevent telescopic nose turning after it

has been installed.

• Move the headstock to its "all the way back"

position and measure the dimension (L). Push

the telescopic nose to the end of travel (less 5

mm) and cut tube (D) to the value measured.

• Move the headstock to its "all the way

forwards" position. Install the sleeve on the

plate (F).

• Check smooth sliding of the telescopic nose by

moving the headstock forwards and backwards.

Loading...

Loading...