5 - ADJUSTMENT AND SETUP SMART320

EN

5 - Pag. 5 / 20

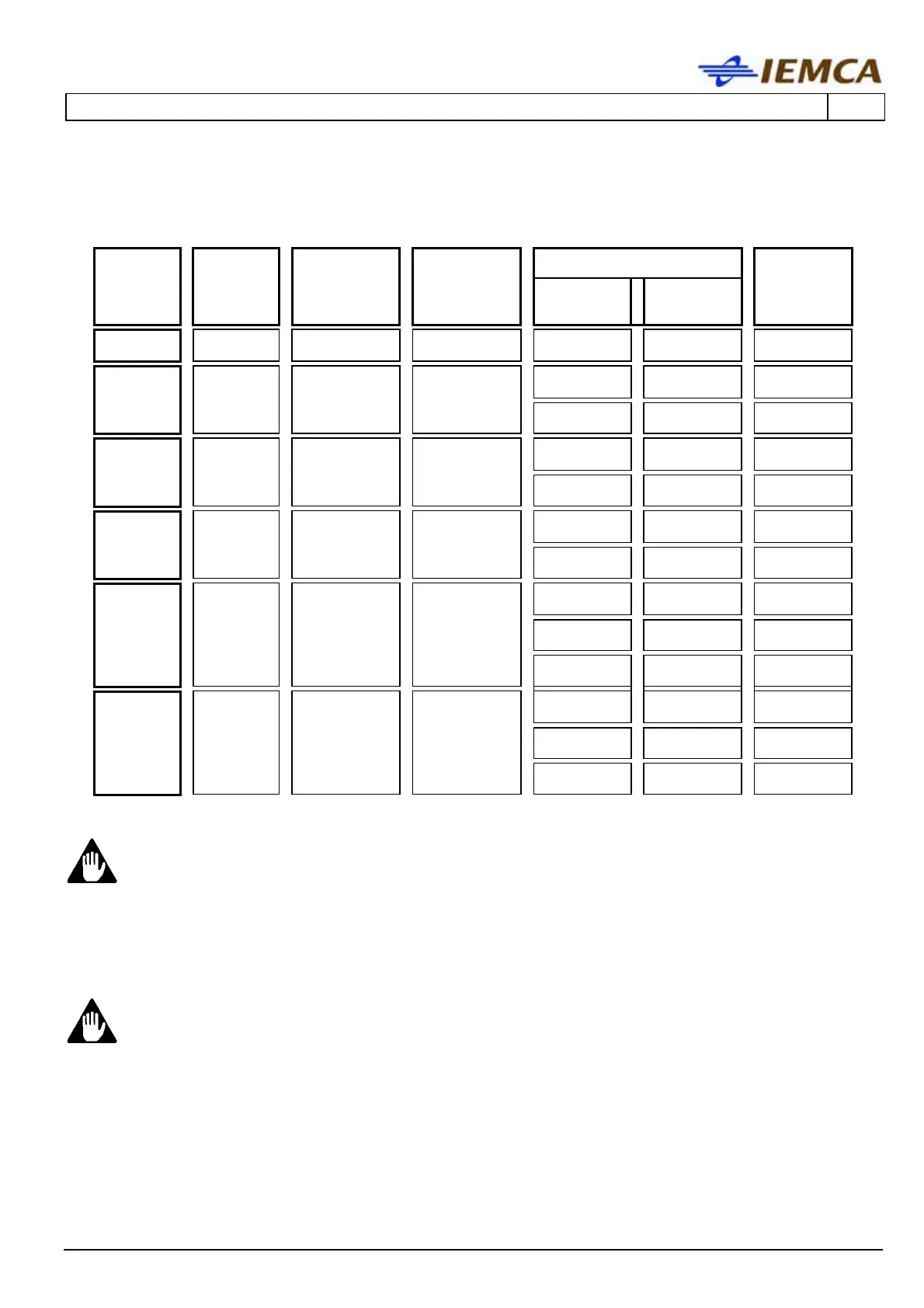

Guide channel, bar pusher, bar and pipe diameters SMART 320.

Bar diameter (mm)

Bar lathe

passage

(mm)

Guide

channels

diameter

(mm)

Bar pusher

diameter

(mm)

Revolving

tip diameter

(mm)

MIN MAX

Pipe max

diameter

(mm) (*)

8

8

7 7,5 3 (1/8”)

5,5

(7/32”)

7 (9/32”)

9

10/7 8,5 4 (11/64”)

6,5

(17/64”)

8 (5/16”)

11

11

10 10,5 4 (11/64”) 8 (5/16”)

10

(13/32”)

11

12/10 10,5 4 (11/64”) 8 (5/16”)

10

(13/32”)

13

13

12 12,5 4 (11/64”)

10

(13/32”)

12

(15/32”)

16

16/15 15,5 5 (13/64”)

13

(33/64”)

15

(19/32”)

17

17

16 16,5 5 (13/64”) 14 (9/16”)

16

(41/64”)

19

18,5 6 (1/4”)

16

(41/64”)

18

(23/32”)

20

20/18

19,5 6 (1/4”)

17

(43/64”)

19 (3/4”)

21

21

20 20,5 6 (1/4”)

18

(23/32”)

19 (3/4”)

22

21,5 8 (5/16”)

18

(23/32”)

20

(51/64”)

23

23/20

22,5 8 (5/16”)

20

(51/64”)

20

(51/64”)

24

24

23 23,5 8 (5/16”)

20

(51/64”)

20

(51/64”)

(*) Valid also for prepared bars or normal bars machined with front remnant ejection.

WARNING – CAUTION:

barstock diameters for any guide channel are only given as an example. If the

diameter is approximately 8 mm smaller than the guide channel diameter this

may cause the bar feeder vibration and failure. Therefore, it may be necessary

to slow down the bar rotation speed or to change the guide channel diameter in

order to obtain the best performance for a specific application.

WARNING – CAUTION:

the collet external diameter should be at least 0.5 mm smaller than the bar

pusher external diameter.

Loading...

Loading...