10–15

Transpector CPM Operating Manual

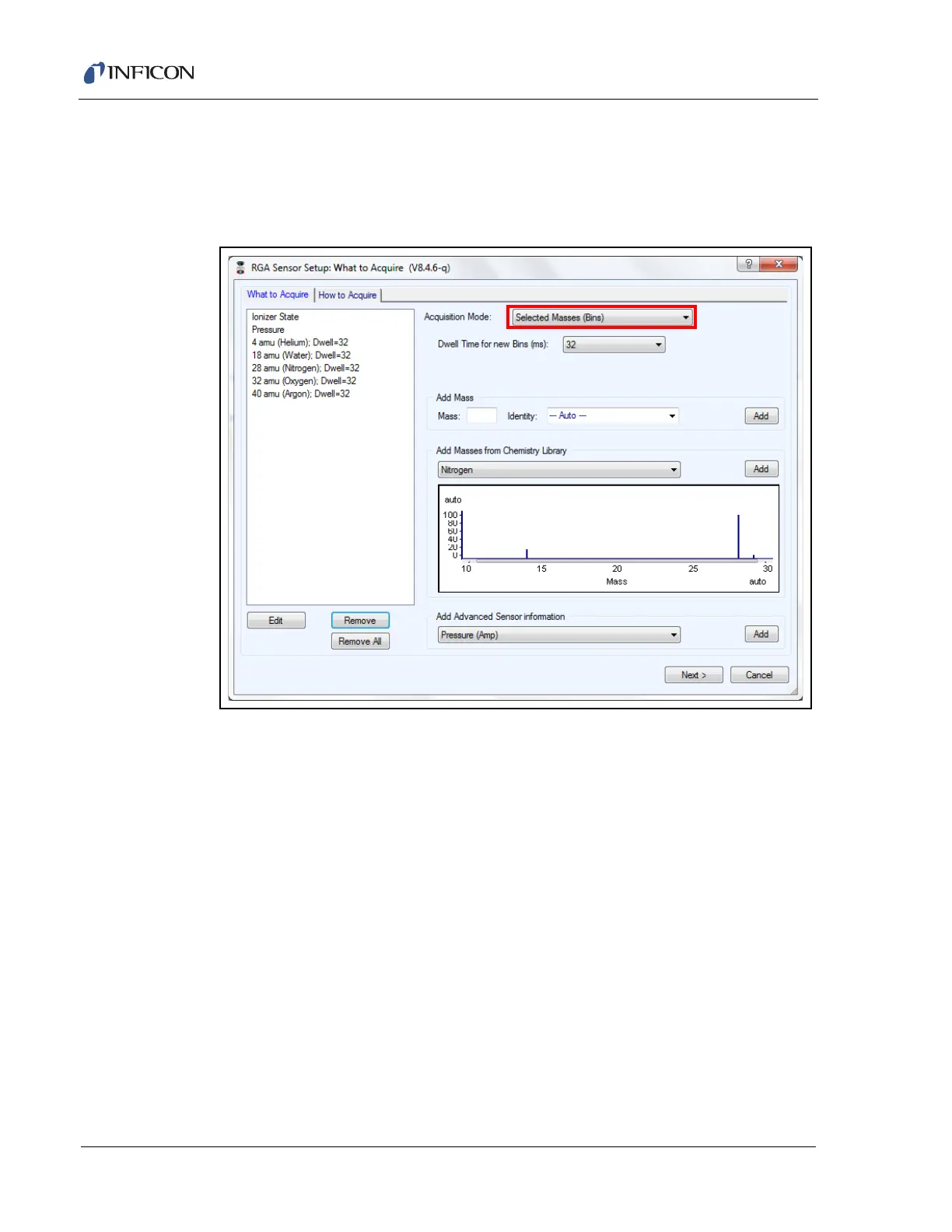

10.6.1.2 Selected Masses Mode

It is possible to define specific masses of interest in Selected Masses Mode.

Transpector CPM advanced sensor functions can be tracked as individual bins in

this data acquisition mode. (See Figure 10-23.)

Figure 10-23 Selected masses mode

Loading...

Loading...