4–6

Transpector CPM Operating Manual

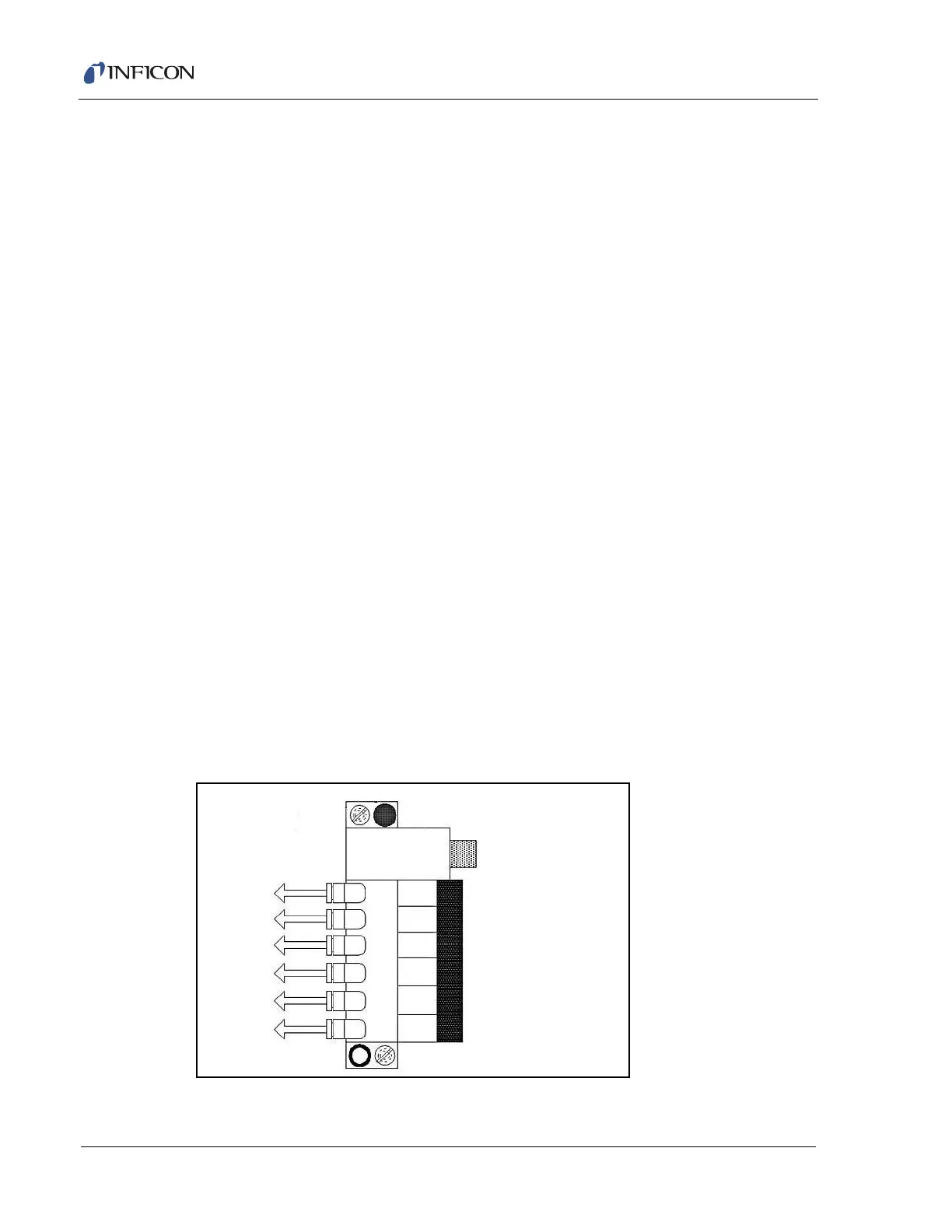

4.3.5 Solenoid Valves

The solenoid-controlled valves are a group of valves joined together as one

manifold assembly which is mounted to a bracket on the Turbo Molecular Pump

foreline block. The valves are controlled either by the CPM controller rocker

switches or the Valves Aux I/O connector.

When solenoid valves are activated, compressed air from the input air supply

(ranging 58–100 psi (gauge) (4–6.9 bar) [400–690 kPa]) will open the appropriate

valve. The recommended setting is 75-80 psi (gauge) (5.17 to 5.52 bar) [517 kPa

to 552 kPa]. All valves are electropneumatically operated. There are six solenoid

valves: (See Figure 4-3.)

V0—Foreline isolation valve and nitrogen purge valve on corrosive systems.

Automatically opened and closed by the start/stop of the pumping system.

V1—Low pressure orifice valve for the HexBlock or the capillary sampling option.

Configured depending on the application. Typically used for background

monitoring.

V2—High pressure orifice valve for the HexBlock or the capillary sampling option.

Typically used for process pressure sampling. User configured depending on the

application.

V3—High conductance valve (1 mT maximum nominal pressure)

V4—Bypass valve used in conjunction with the high pressure bypass option or the

capillary sampling option

V5—Calibration reference

For more details about the function of each valve, see section 6.1.1 on page 6-2.

NOTE: Each solenoid has a red indicator that illuminates when the solenoid is

activated.

Figure 4-3 Solenoid valve block

Exhaust Muffler

Air Supply

Line Connection

9-Pin D Connector

Air

Lines

To

Valves

V3

V1

V0

V2

V5

V4

Loading...

Loading...