6–3

Transpector CPM Operating Manual

6.1.1.1 Hex Block Process Connections

6.1.2 Calibration Option

A single source of gas mixture will accomplish two calibration functions:

Mass scale calibration

Partial pressure reference levels

NOTE: Selection of the appropriate gas mixture components is dictated by the

mass range desired.

Test Mix 1 composition is listed in Table 6-2. The method of delivery is a flow

reference with a remote on/off valve (V5). The gas flow rate is calibrated at the

factory and is kept small (typically 1x10

-4

Torr-L/s) by a sintered leak. Flow through

the leak element is viscous, therefore the gas composition in the reservoir is not

altered by sampling. The pumping system does not allow other valves to be opened

with the calibration reference to ensure that no calibration mix enters the tool.

NOTE: Refer to the software operating manual for more information regarding

Mass Tuning. Results using FabGuard Explorer or FabGuard with this

calibration mixture may be different than shown above due to the

programming of the ionization probability and material factors.

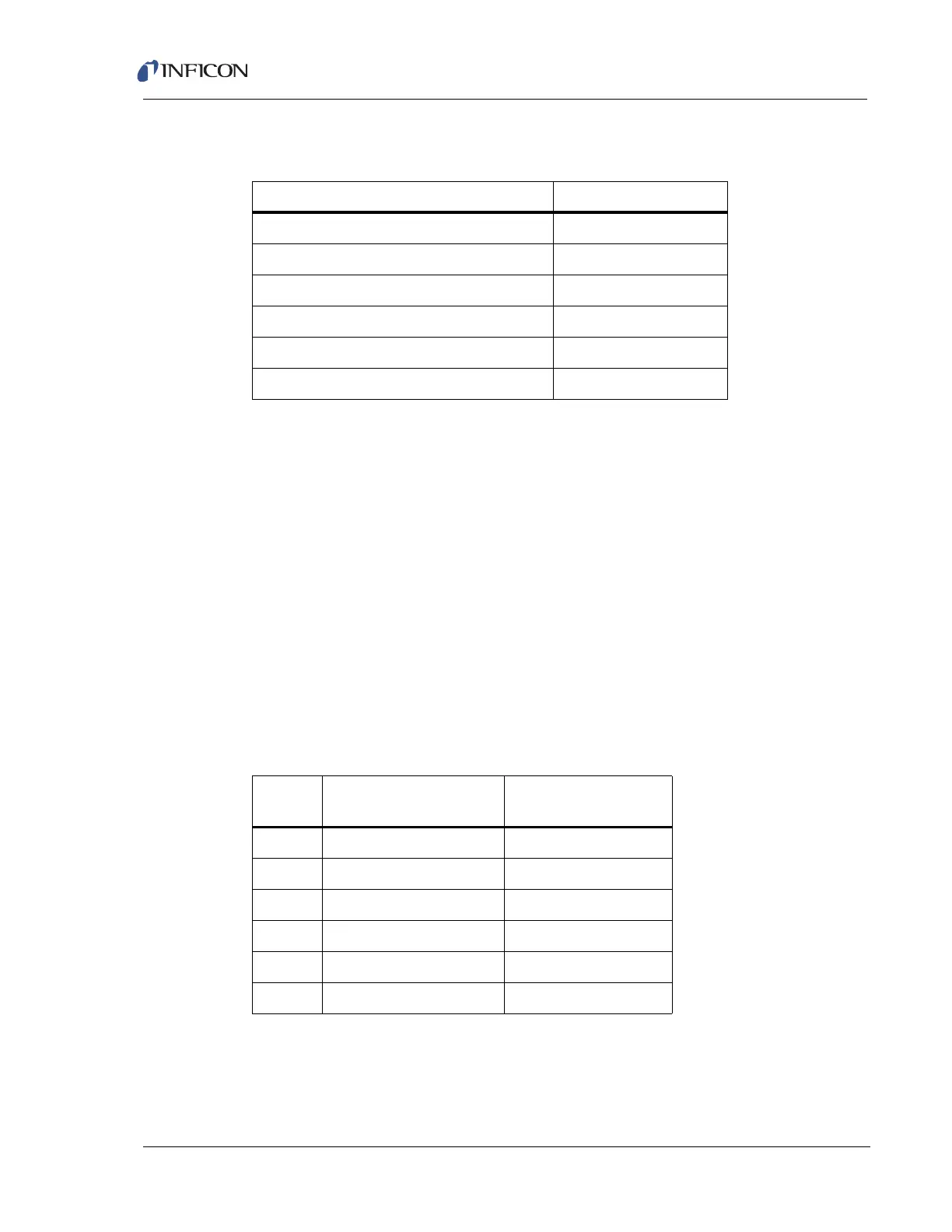

Table 6-1 Hex block process connections

Types of connections Part Number

KF25 In-line connection 923-700-G1

KF40 In-line connection 923-701-G1

CF40 In-line connection 923-702-G1

KF25 90 degree elbow connection 923-703-G1

KF40 90 degree elbow connection 923-704-G1

CF40 90 degree elbow connection 923-705-G1

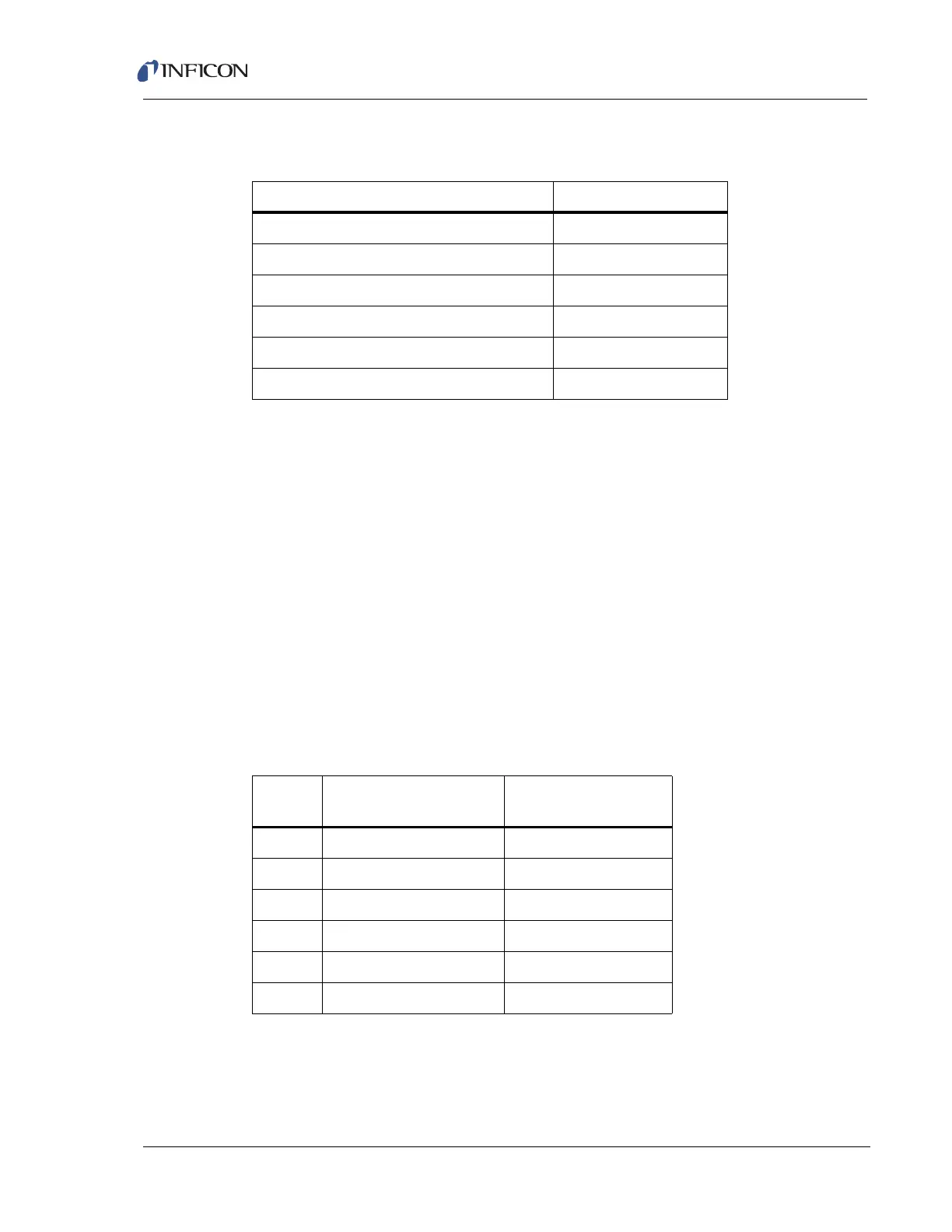

Table 6-2 Mix 1: Calibration mixture of selected impurities in argon

Component

(Composition)

Calibration Masses

Mix 1 H

2

(1%) 2

He (1%) 4

N

2

(1%) 28

Ar (Balance) 36, 38, 40

Kr (1%) 84

Xe (1%) 134, 136

Loading...

Loading...