8–2

Transpector CPM Operating Manual

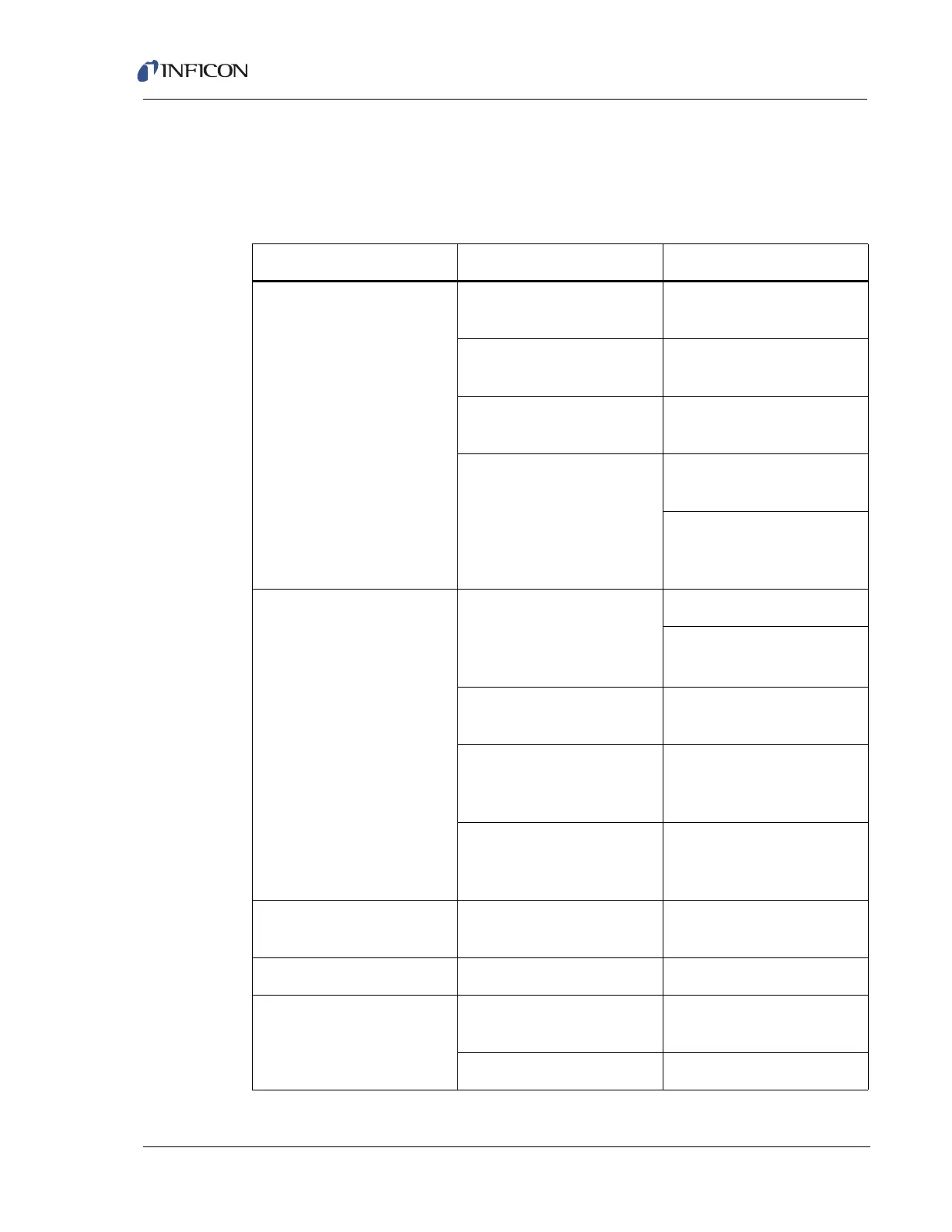

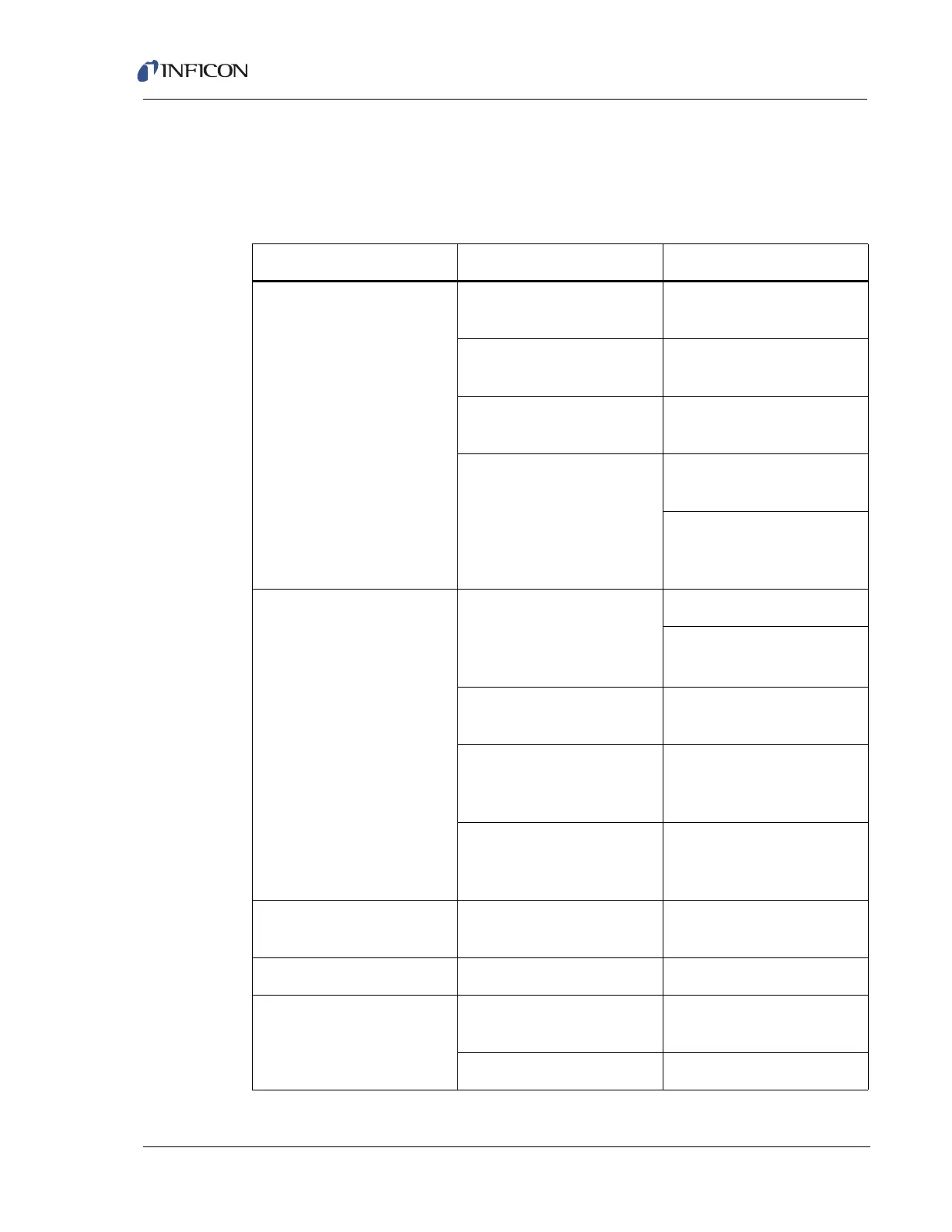

8.3 CPM Symptom—Cause—Remedy Chart

Before proceeding, make sure that the insulation on all cables is intact. There must

be no damage to the insulating material. If there is, replace the cable

.

Table 8-1 Symptom—Cause—Remedy Chart

SYMPTOM CAUSE REMEDY

CPM will not pump down Forepump not

plugged in

Connect cable to controller

Control cable missing or

bad connection

Check control cable

Foreline isolation valve not

opening

Check valve actuation

Digital Pressure Switch

defective or not within

required pressure range

Replace the Digital

Pressure Switch

Verify incoming pneumatic

pressure is between 58 and

100 psi

Turbo Molecular Pump

does not reach operating

speed

Foreline pressure too high

due to gas leak or

forepump diaphragm

failure

Find Leak(s).

Replace diaphragm. (refer

to section 7.6 on page 7-6)

Turbo Molecular Pump

bearing drag excessive

Replace pump

Foreline pressure too high

due to water vapor in

foreline hose

Run pumpdown and purge

with dry gas

No pneumatic pressure

applied to the foreline valve

Check supply and

connections to the foreline

block valves

Turbo Molecular Pump is

noisy

Bearing failure Replace pump

Diaphragm Pump is noisy Loose Diaphragm Tighten Diaphragm

Analyzer pressure high

with sampling valves

closed

Leaks in manifold or

orifices

Tighten or replace gaskets

Seat leaks to process gas Replace seat or valve

Loading...

Loading...