–

170

–

Feed pitch error will be caused unless the

tension is proper.

(1) Replacing the top feed belt

24-1 Replacing procedure of feed belt

Caution : The standard of the time of replacement is one year although it depends on the frequency of use.Replace the

belt with a new one when it is observed that feed force is excessively deteriorated or the like.

Caution : Perform periodical cleaning approximately once a week since dust is collected inside the top feed cover and

the belt rolls the dust resulting in feed trouble or short life of the belt.

■

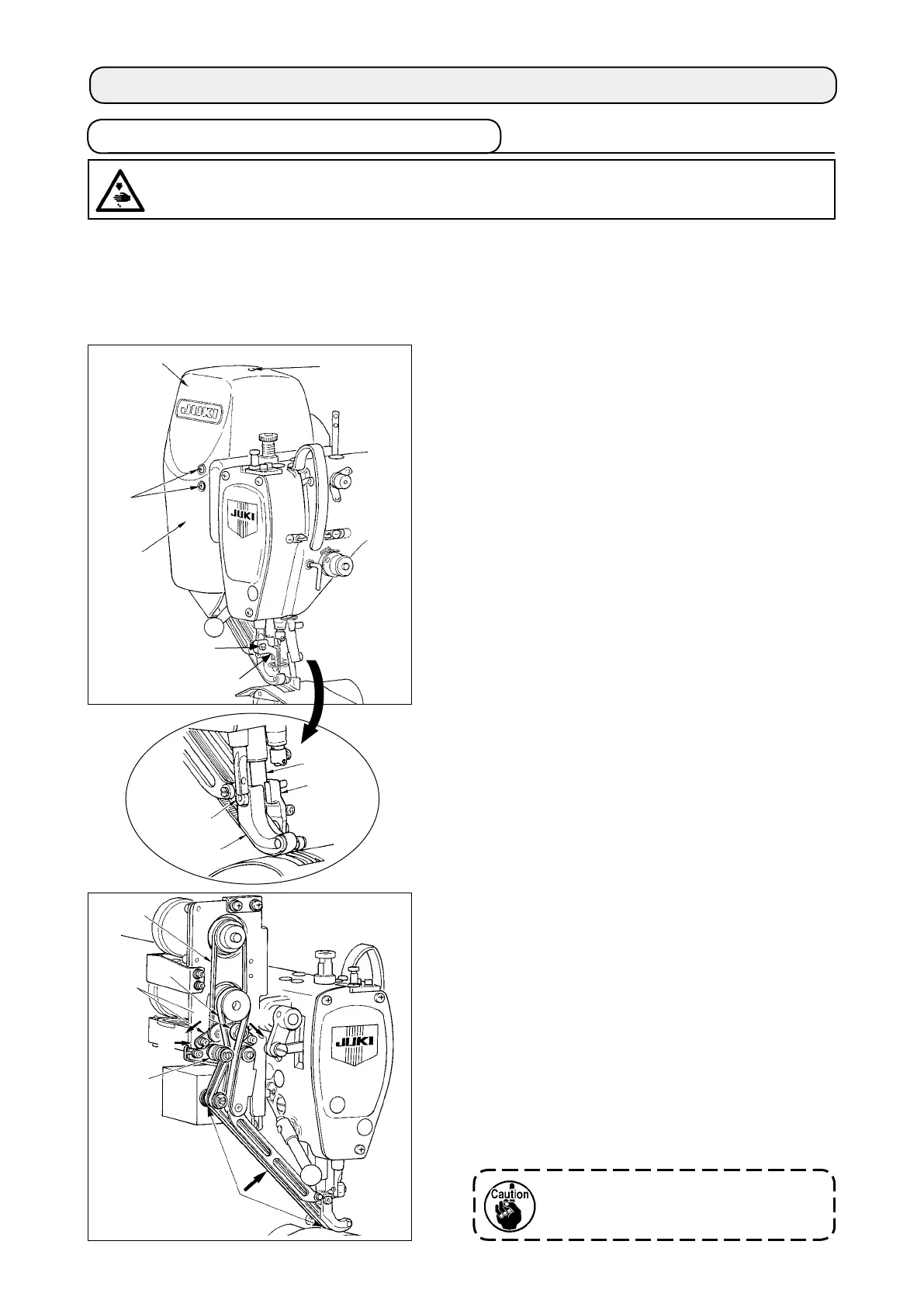

Belt tension adjusting procedure

(1) Main feed belt :

Move tension adjustment plate L

!2

to the left or

right to adjust the belt.

• The tension is increased in the right-hand

direction (direction A) and decreased in the left

direction.

(2) Auxiliary feed belt :

Move tension adjustment plate S

!3

to the left or

right to adjust the belt.

• When it is opened on both sides (direction B),

the tension is increased, and when it is closed,

the tension is decreased.

(3) Adjusting the belt tension value :

1) Main feed belt :

The belt has to be bent by 3 mm when it is

pressed with a load of 1.3N (130gf).

2) Auxiliary feed belt :

The belt has to be bent by 3 mm when it is

pressed with a load of 0.4N (40gf).

24. MAINTENANCE

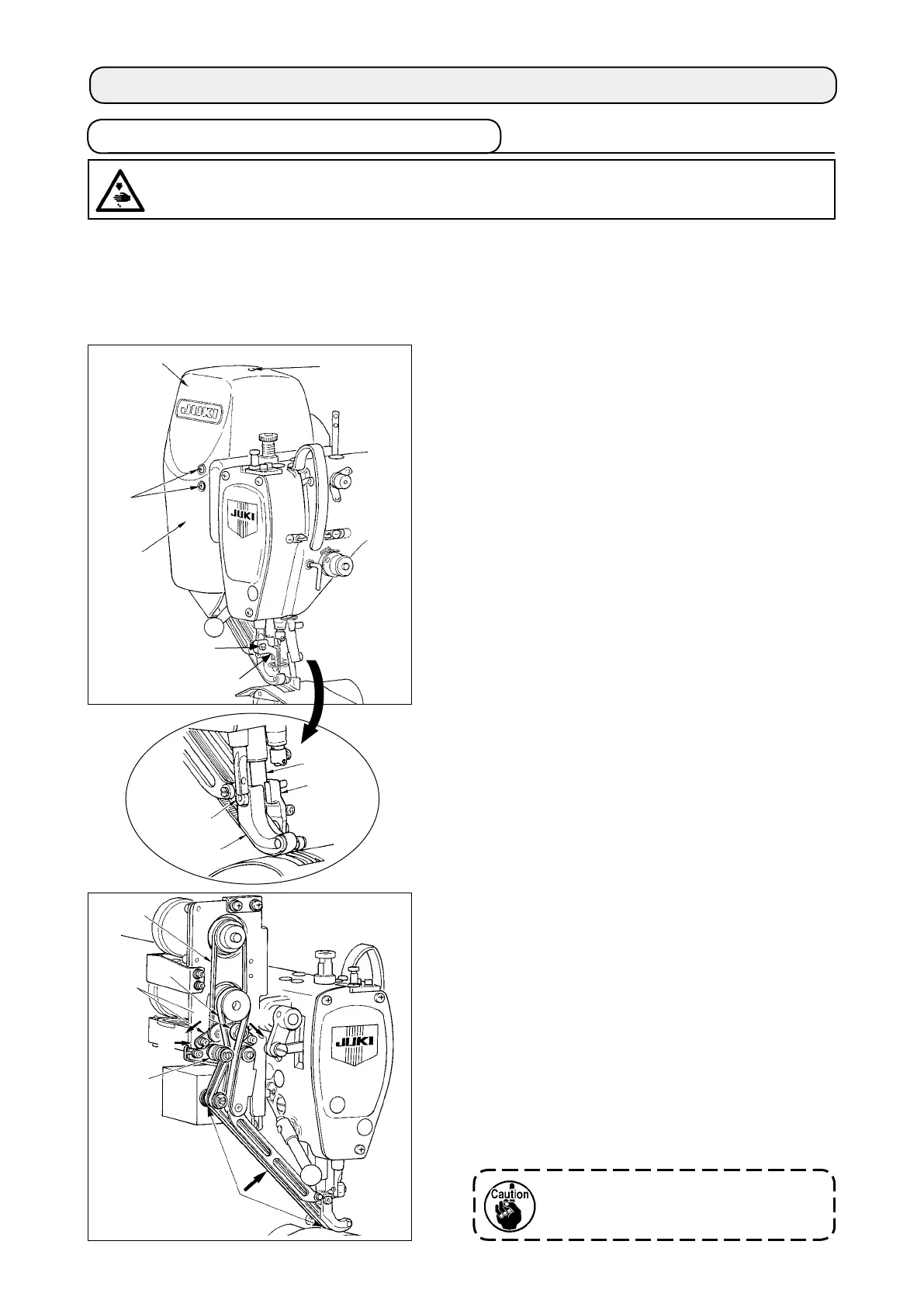

1) Remove ten cover setscrews

1

and remove

coverR

2

and cover F

3

.

2) Loosen intermediate presser foot screw

!0

and

remove intermediate presser foot

!1

.

3) Loosen walking foot setscrew

4

and remove

walking foot

5

and auxiliary walking foot

6

.

4) Remove main feed belt

7

and auxiliary feed belt

8

, and replace them with new ones.

5) Put walking foot rod

9

between

5

and

6

, and

x with screw

4

.

6) After adjusting the belt tension, attach cover R

2

and cover F

3

.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

4

5

9

6

1

1

2

Press the center.

8

7

!2

!3

3

A

B

B

!0

!1

Loading...

Loading...