–

176

–

1) Adjusting the engraved marker dot

Loosen knife drive arm clamp screw

4

, turn

knife drive arm

5

so that engraved marker dot

1

aligns with V groove

2

, and tighten the clamp

screw.

When V groove

2

in terms of engraved

marker dot

1

slips in the right-hand

direction, the blade section of moving

knife does not completely pass the blade

section of counter knife. As a result,

handling failure or thread trimming

failure will be caused.

When pulley cover engraved marker

dot

2

aligns with engraved marker dot

(colorless)

1

on the handwheel, the

timing is normal.

■

When the aforementioned normal timing is

improper, adjust it with the procedure below.

1) Remove the bottom cover and loosen thread

trimmer cam setscrews

7

.

2) Adjust engraved marker dot (colorless

1

) on

the handwheel to engraved marker dot

2

on the

pulley cover.

3) Pressing drive block

3

to the right-hand,

engage cam

4

with roller

5

.

4) Turn cam

4

only in the reverse direction of

the rotating direction of the hook driving shaft

without turning hook driving shaft

6

.

5) Press cam

4

to roller

5

at the position where

cam

4

does not turn and tighten cam setscrews

7

.

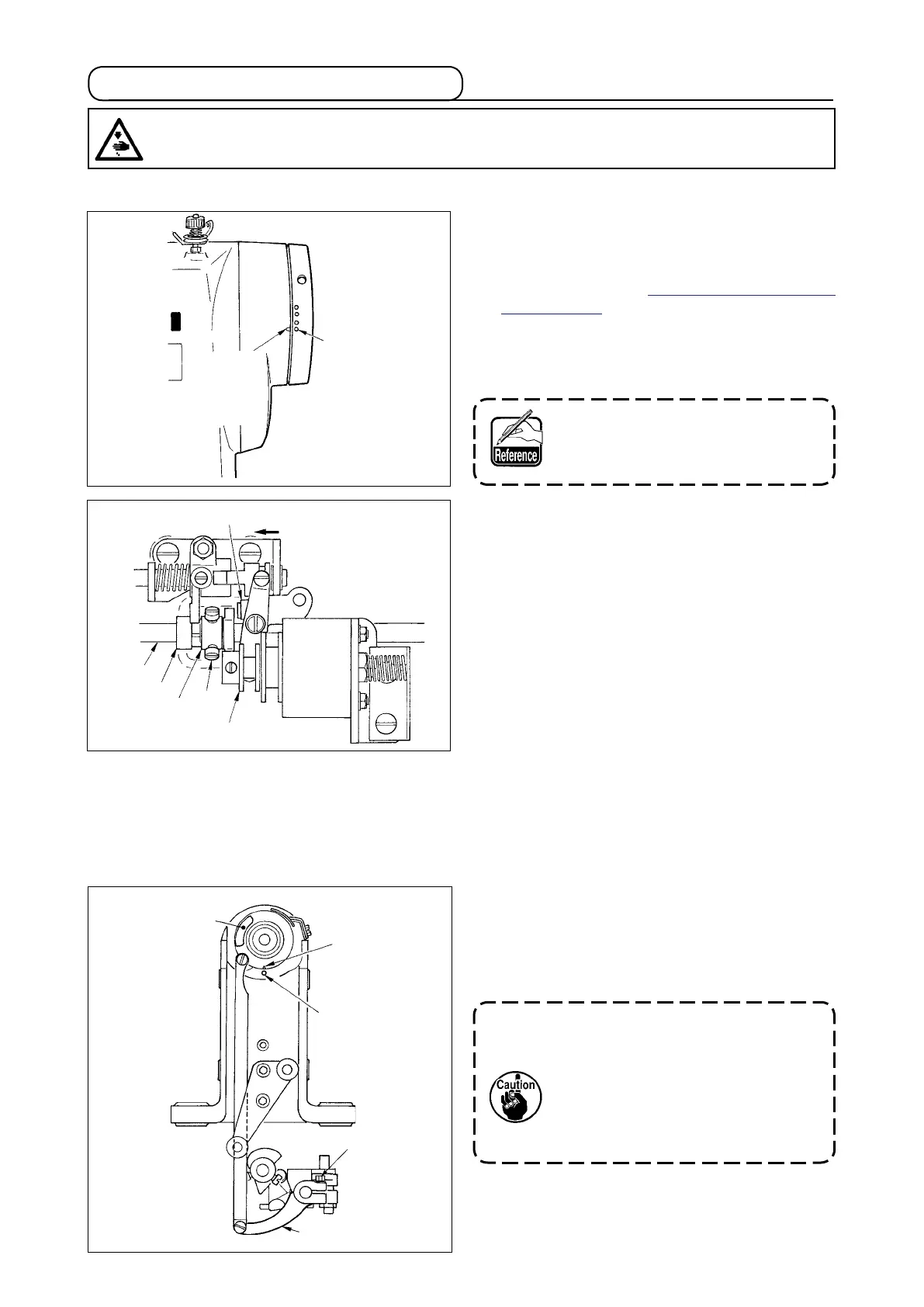

(1) Adjusting the thread trimmer cam timing

1) Turn the handwheel to the position where the thread

take-up lever comes a little before its upper dead point.

2) Turn ON the thread trimmer solenoid and slide the

roller to the thread trimmer cam to engage them with

each other referring to

"21-7 Performing the output

signal check"

, and slide the roller to the thread

trimmer cam to engage with each other.

3) In the state as it is, turn the handwheel in the normal

operating direction and in the reverse direction. Then

turn the handwheel until the handwheel stops.

24-5 Adjusting the thread trimmer

5

6

8

4

7

3

Slide

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Engraved marker

dot (colorless)

1

Engraved

marker

dot

2

3

2

1

4

5

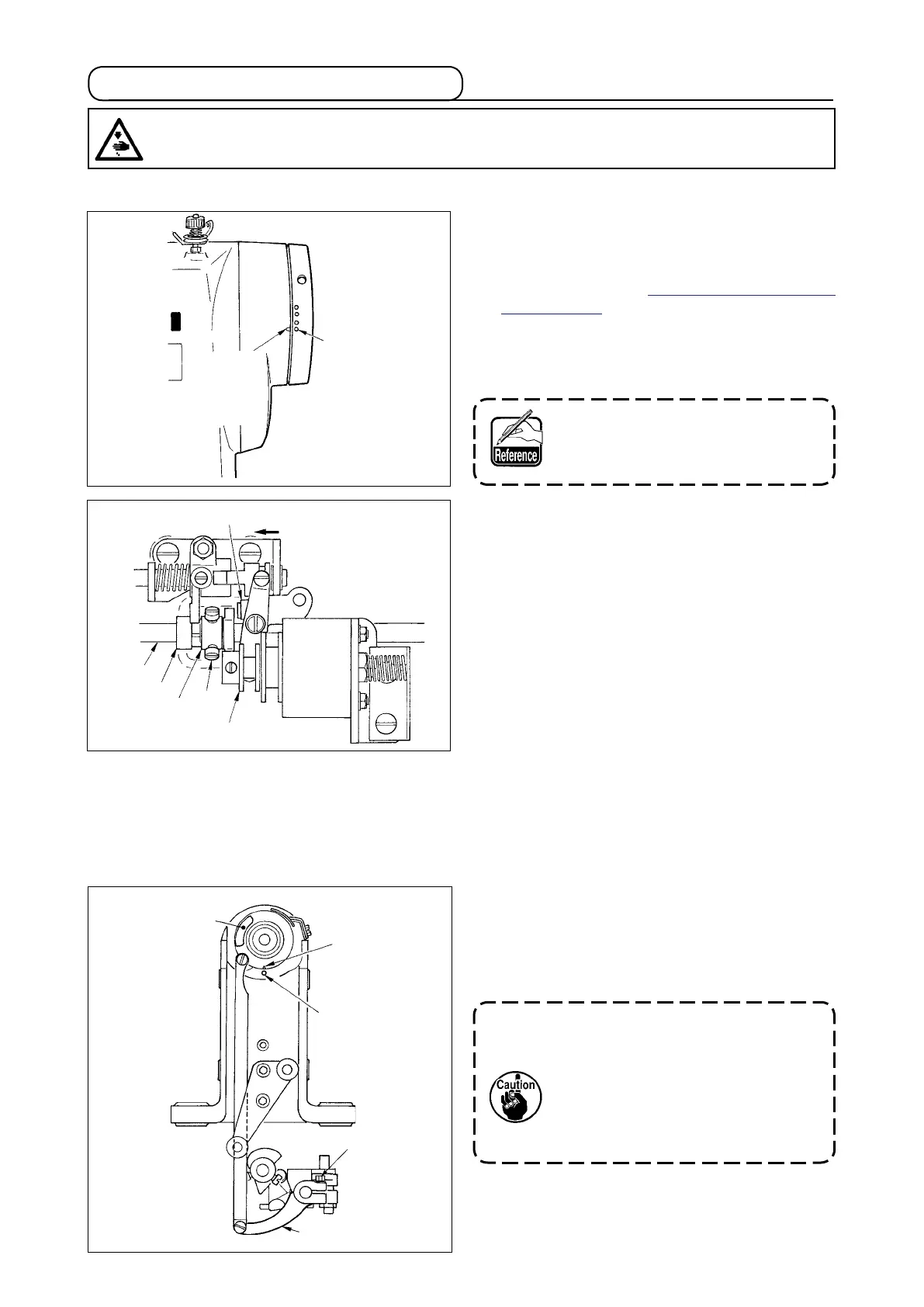

(2) Adjusting the initial position of the moving knife

The initial position of the moving knife is the position where engraved marker dot

1

on the hook shaft

base aligns with V groove

2

on the moving knife base.

At this time, end

6

of the cam roller is higher by 1.7 mm than hook driving shaft center

7

.

Loading...

Loading...