–

173

–

3

6

4

9

8

!0

!2

!1

7

1

2

5

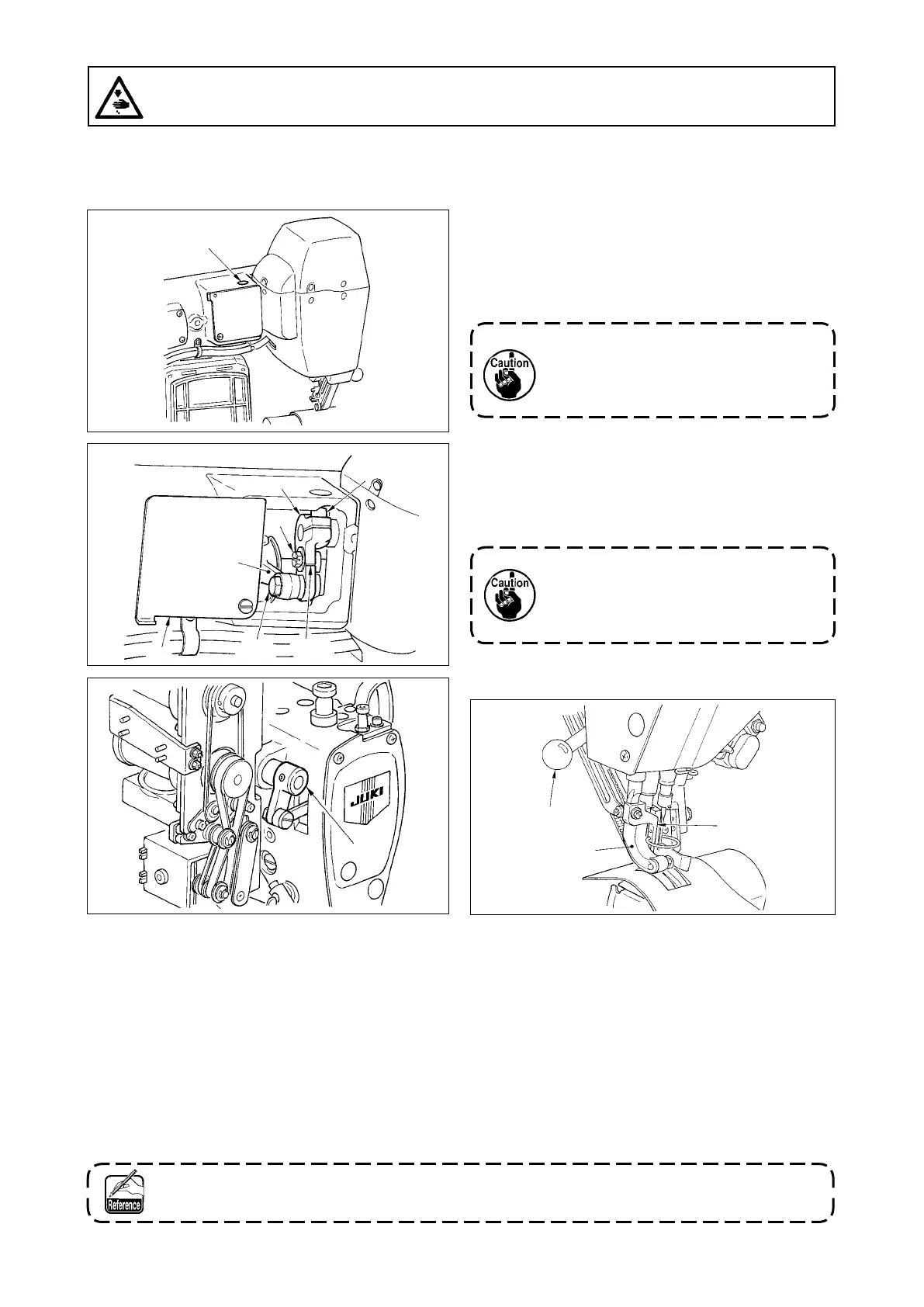

(1) When making equal the amount of alternate vertical movement of walking foot

and presser foot (When making the amount equal to 1.5 mm)

1) Bring the needle bar to its lower dead point.

2) Turn presser lever

1

, raise walking foot

2

, and

insert "thickness gauge" of 1.6 to 1.7 mm or the

like between the top feed belt and the bottom

feed belt.

6) Turn presser lever

1

and remove the thickness

gauge which has been inserted in step 2).

In case of 1.5 mm, thickness of 1.6 to

1.7 mm is settled since the compressed

amount of belt slightly varies due to the

presser pressure.

3) Remove stopper plug

3

.

4) Insert a hexagonal wrench key from hole A, and

loosen top feed arm clamp screw

4

.

5) Tighten clamp screw

4

after checking that

presser foot

5

has come down.

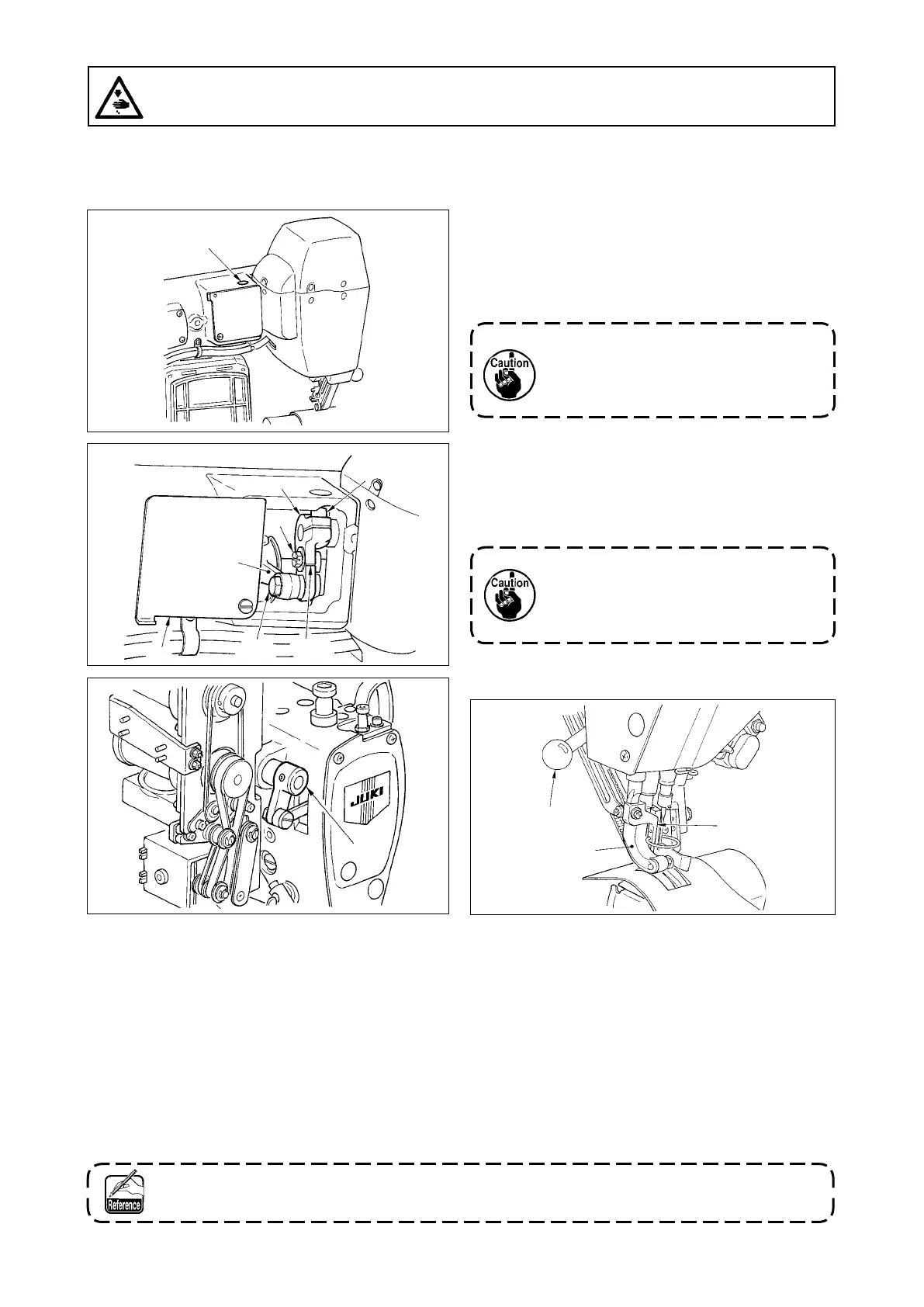

(2) When making 2.5 mm the amount of alternate vertical movement

(When the amount is already made equal to 1.5 mm, perform from item 1) below. When the amount

is not made equal to 1.5 mm, Perform rst "(1) When making equal the amount of alternate vertical

movement" of the aforementioned item.

1) Turn top feed arm cover

8

.

2) Loosen stopper screw

9

and remove the stopper.

3) Loosen top feed hinge screw

!0

.

4) Turn cam rod

!1

, adjust the position to the engraved marker line on top feed arm

!2

, and tighten hinge

screw

!0

.

1. Remove the thrust of top feed arm

6

and drive shaft arm

7

.

2. Set the tightening torque to 5.8N•m

(60Kgf • cm).

When turning the cam rod and bringing the top feed arm to its top end, the amount of

alternate vertical movement becomes 3.5 mm.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

A

Loading...

Loading...