–

175

–

(2) Adjusting the hook

1) Loosen three setscrews in the hook, turn

the handwheel, and adjust needle bar

engraved marker line

B

to bottom end

6

of needle bar bushing.

2) Adjust blade point

7

of hook to the

center of needle

8

so that the clearance

between the blade point and the needle

is 0.04 to 0.1mm (standard).Then tighten

the setscrews in the hook.

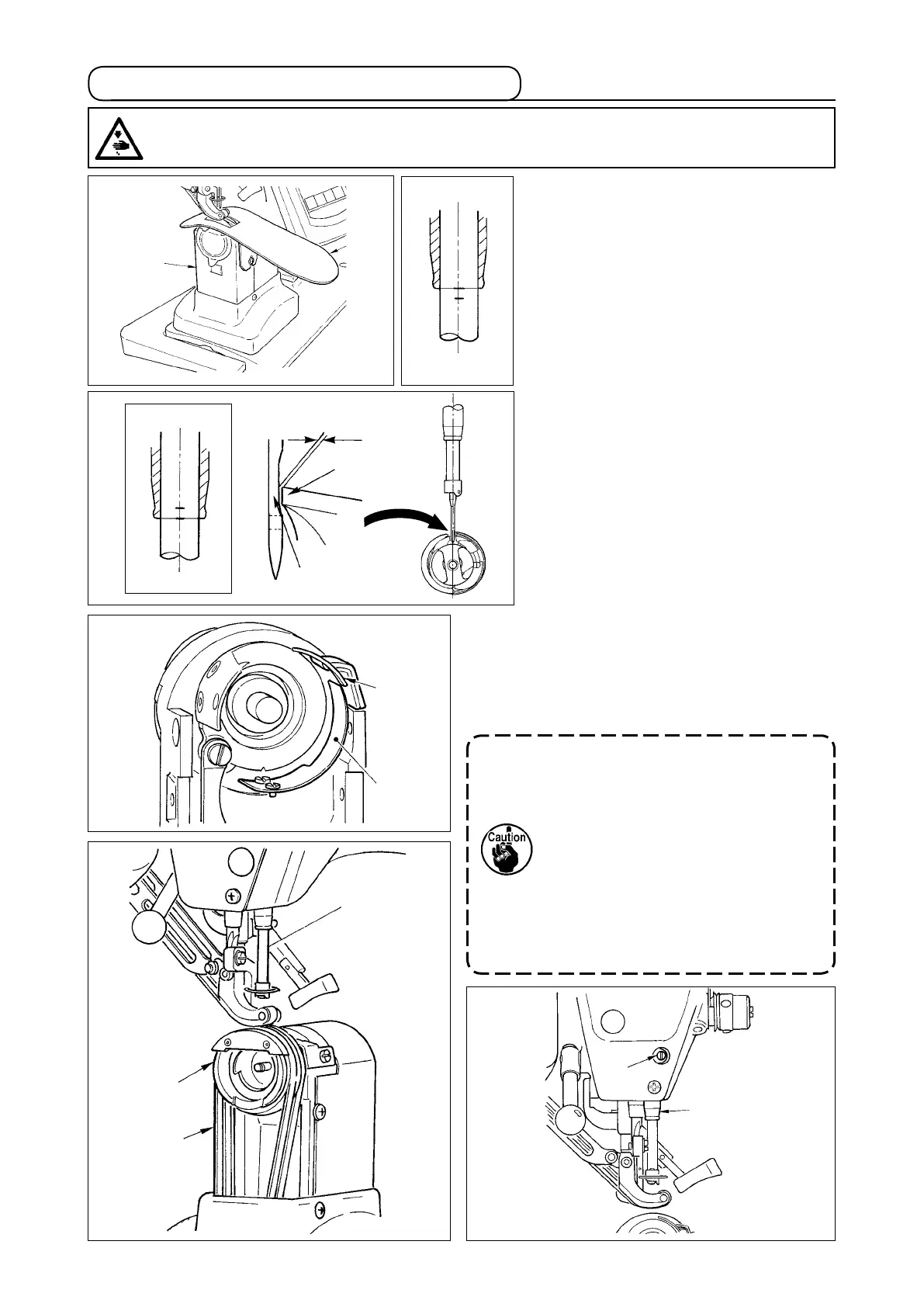

3) Put bottom feed belt

9

to hook base

3

, and

assemble it to the hook shaft base.At this time,

adjust the clearance between the bottom surface

of the feed foot (bottom surface of top feed belt)

and the top surface of the bottom feed belt to 0.1

mm at the upper dead point of the needle bar.

1. When the clearance is excessively smaller than

the specified value, the blade point of hook

is damaged, and the clearance is excessively

larger, stitch skipping will be caused.

2. Fit counter knife guard

!0

located inside the

hook base to the inside of counter knife

!1

since lift trouble will be caused.

3. RP hook (dry hook) rolls thread waste or cloth

dust, and there is a possibility of breakdown or

sewing trouble. Periodically perform cleaning

of the hook.

24-4 Adjusting the needle and the hook

1

2

!0

!1

0.04 to 0.1 mm

B

7

8

4

3

9

6

5

(1)

Adjusting the height of needle bar

1) Remove throat plate auxiliary plate

1

and

hook cover asm.

2

.

2) Remove hook base

3

.

3) Bring needle bar

4

to its lower dead point,

and loosen needle bar bracket clamp

screw

5

.

4) Adjust needle bar engraved marker line

A

to bottom end

6

of needle bar lower

bushing, and tighten clamp screw

5

.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

A

Loading...

Loading...