–

177

–

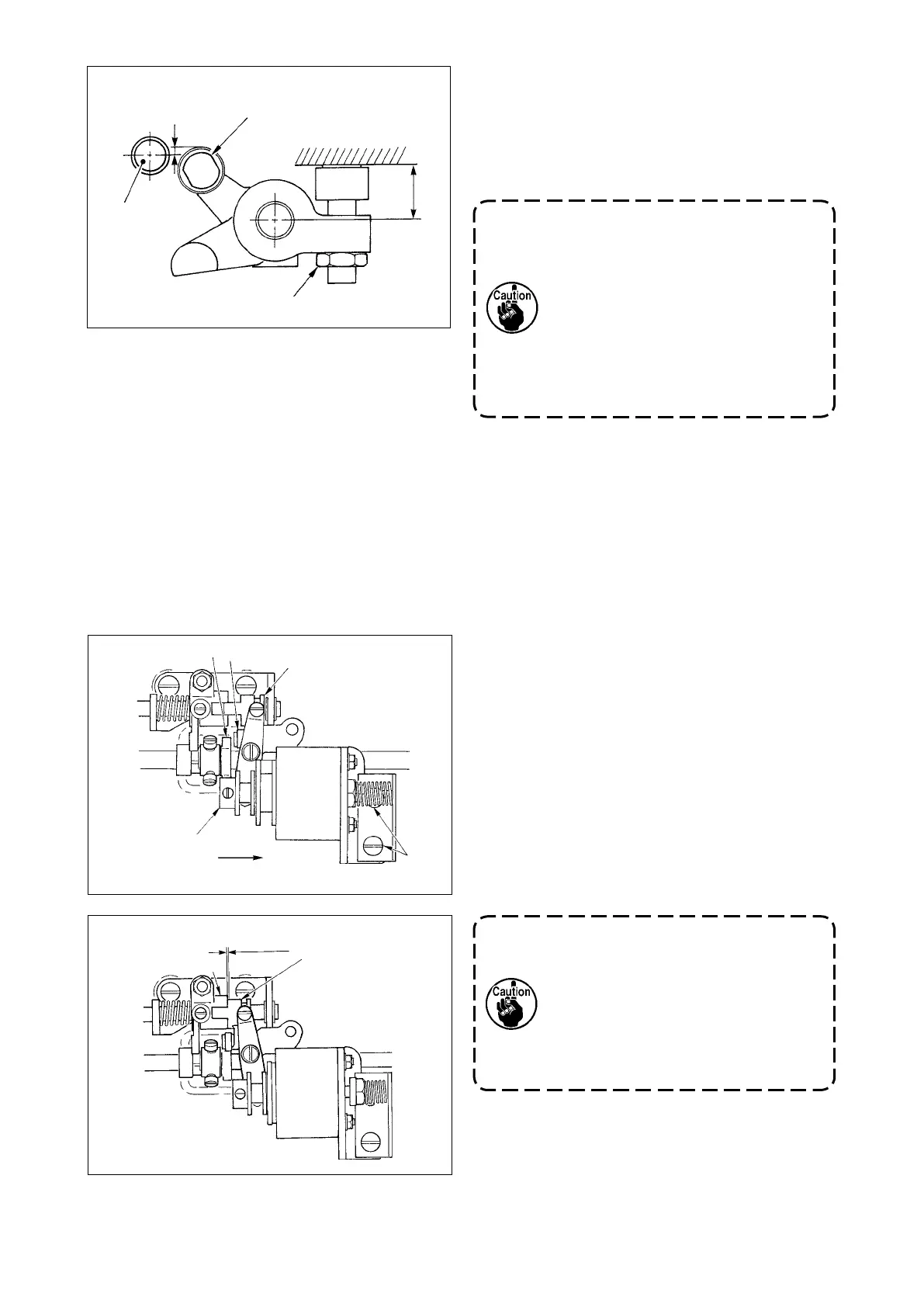

11.8mm

6

7

8

2) Adjusting the position of the cam roller

Loosen stopper lock nut

8

, turn the stopper, and

tighten cam roller

6

at the position of 11.8 mm.

(Refer to the illustration on the left side.)

Bottom surface of

base plate

1. When the position of cam roller

6

is

excessively higher as against hook

driving shaft

7

, the moving knife

rocking stroke is decreased and thread

trimming failure will be caused.

2. On the contrary, the position is

excessively lower, the rocking stroke is

increased and the length of remaining

needle thread is shortened or the blade

point is damaged.

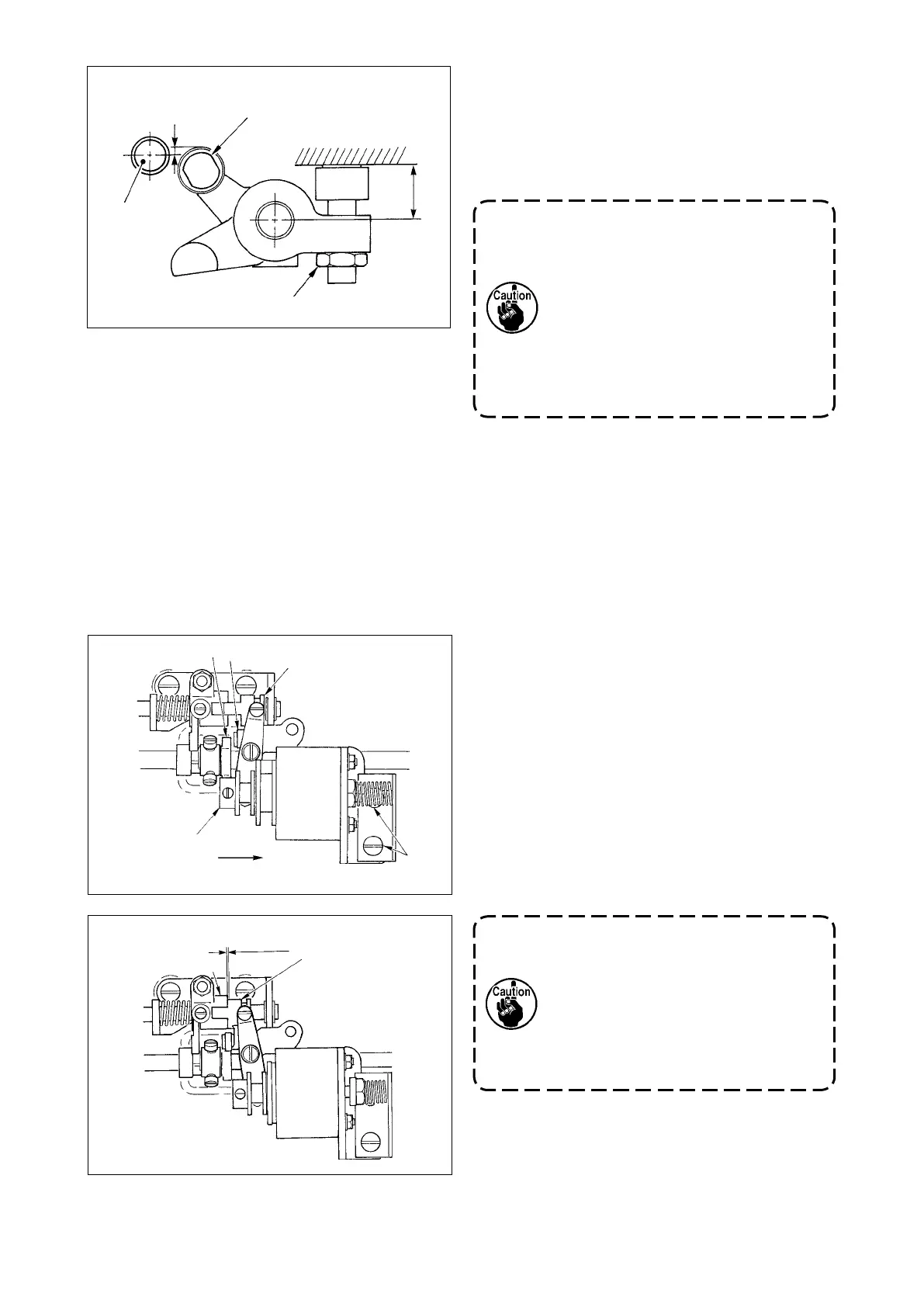

1.7mm

6

5

7

3

4

1

2

1) Remove the bottom cover, press drive block

3

by nger in the direction of arrow mark

A

. At this

time, loosen setscrews

4

and adjust so that the

clearance is 0.1 to 0.5 mm.

2) Take the finger off, and check that there is a

clearance between cam roller

5

and edge

6

of

the thread trimmer cam.

3) Secure an approximate clearance of 0.5 mm

between slide arm

1

and E ring

7

.

(3) Adjusting the initial position of the thread trimmer solenoid

Adjust the initial position so that the clearance between slide arm

1

and drive shaft arm

2

is 0.1 to 0.5

mm when the thread trimmer solenoid performs suction.

1. When the clearance is larger than the

specied value, malfunction of

thread trimming may occur.

2. When the clearance is smaller than

the specied value, the load applied

to each component is increased and

there is a danger of occurrence of

abnormal worn-out.

0.1 to 0.5mm

A

Loading...

Loading...