RPDO 2 can now be used to supply trajectory data for both axes, e.g.:

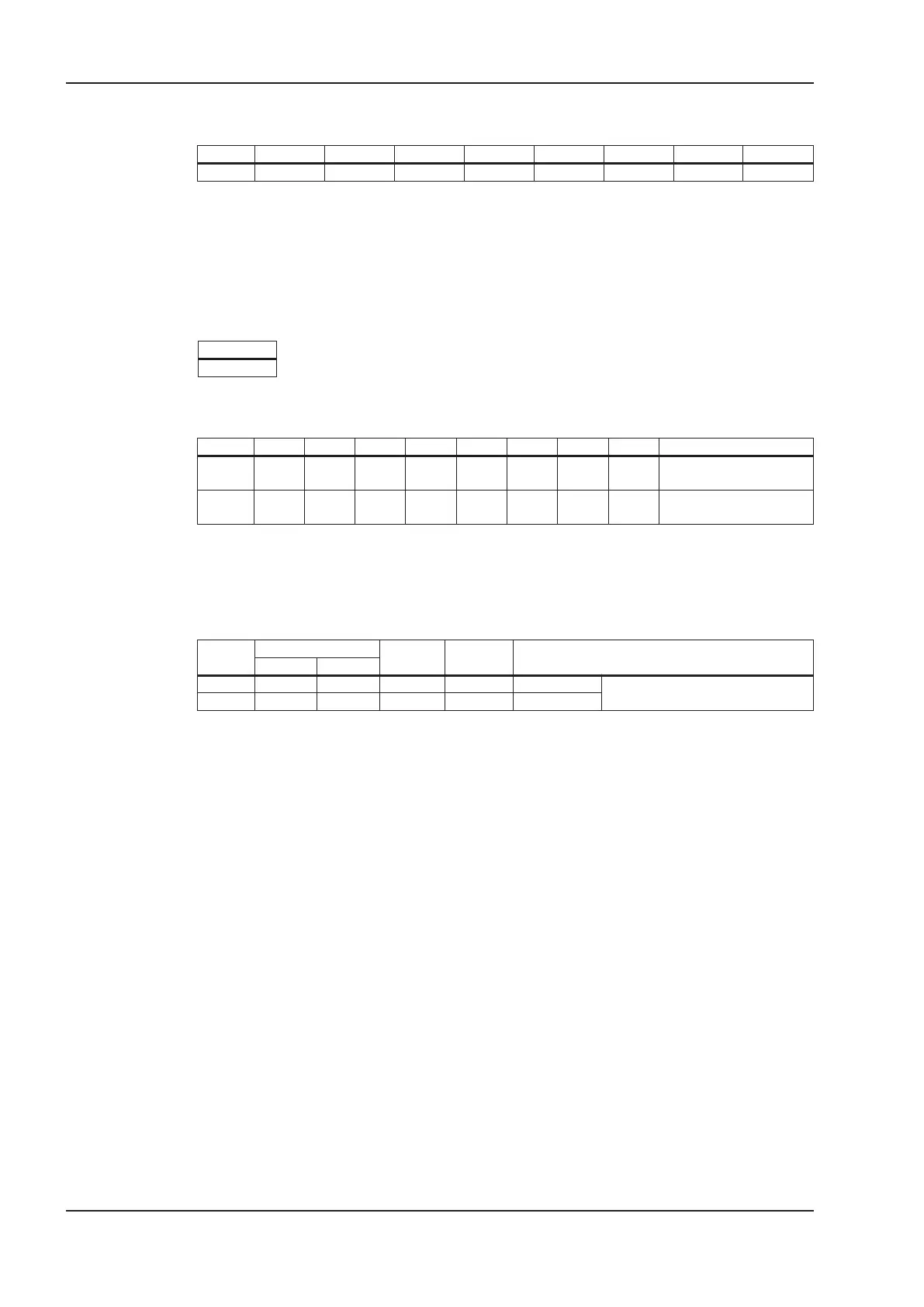

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

301 F4 01 00 00 E8 03 00 00

In this example, the first axis receives a trajectory value of 500 increments (Bytes 0 ... 3) and the

second axis receives a trajectory value of 1000 increments.

The axes accept these values, and the positioning is made when the next SYNC telegram is recei

-

ved.

SYNC telegram

COB-ID

080

Afterwards, both axes send back their incremental positions and the contents of their status regis

-

ters when the SYNC Object with the COB-ID for the 2

nd

TPDO is received:

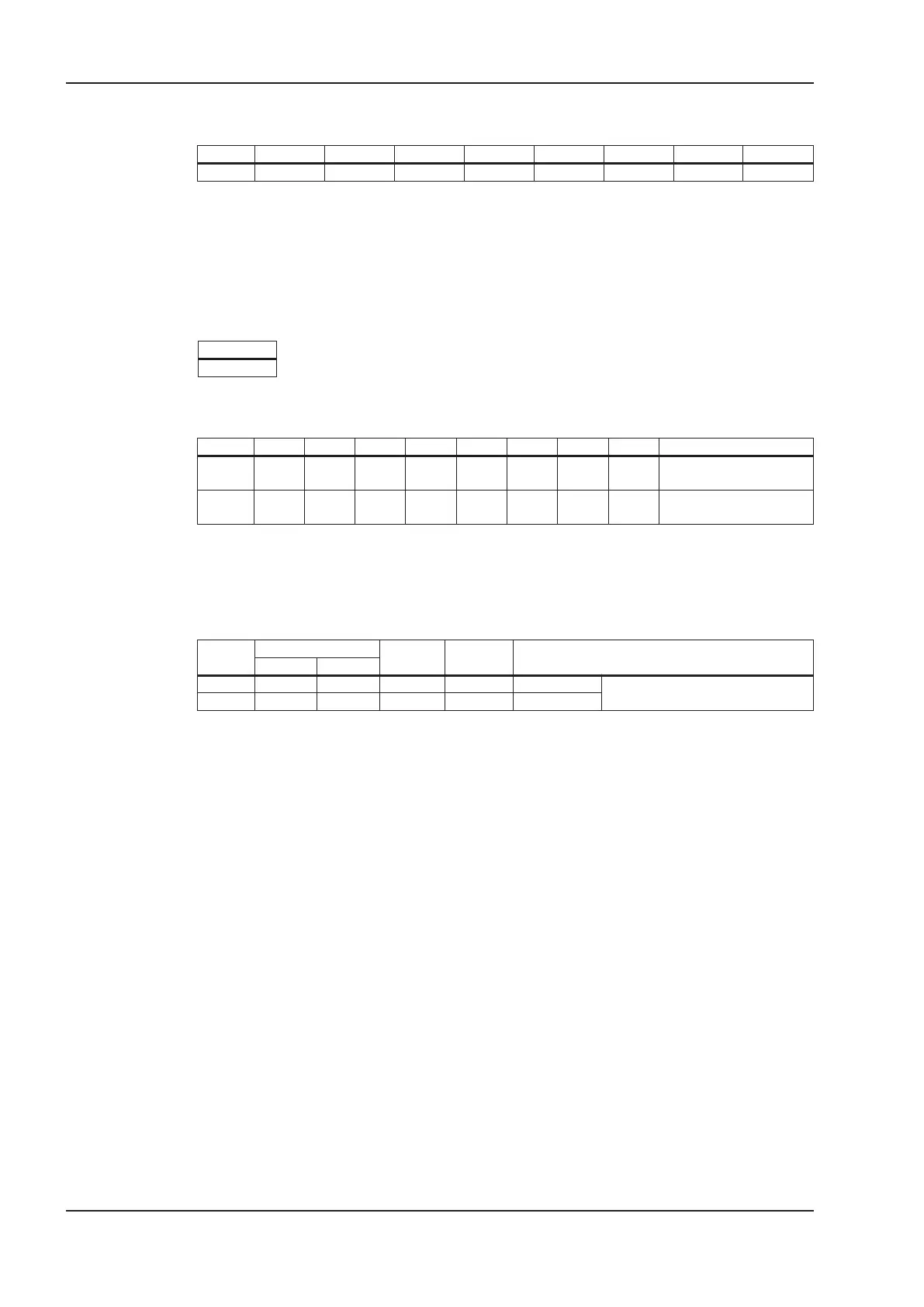

COB-ID Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Comment

181 23 01 00 00 00 00 03 44

position + manufacturer

status register for axis1

182 A5 02 00 00 00 00 03 44

position + manufacturer

status register for axis2

If an error occurs during operation, the axis concerned transmits an Emergency message, which

could appear like this:

Emergency Object

COB-ID

Emergency error

Error

register

Category

Low High

081 10 43 08 01 00 00 00 00

motor temperature, temperature,

manufacturer-specific

081 00 00 08 00 00 00 00 00

132 CANopen for S300/S700

Appendix 11/2018 Kollmorgen

Loading...

Loading...