4 CANopen Drive Profile

4.1 Emergency Messages

Emergency messages are triggered by internal equipment errors. They have a high ID-priority, to

ensure quick access to the bus. An Emergency message contains an error field with pre-defined

error/fault numbers (2 bytes), an error register (1byte), the error category (1 byte) and additional

information (Þ chapter 3). The higher-value byte of the error number describes the error category,

and the lower-value byte provides the error number in this category.

Error numbers from 0000

h

to 7FFF

h

are defined in the communication or drive profile. Error num

-

bers from FF00

h

to FFFF

h

have manufacturer-specific definitions. The error category can be used

to classify the significance of any errors that occur. The following error categories are defined:

1: Errors that can only be cleared by a reset (COLDSTART command, or Bit 7 in the

control word Þ p.58). If you reset the amplifier in case of a cat.1 error, the servo amplifier

will be restarted by a coldstart.

2: Errors that can be cleared by Bit 7 in the control word (Þ p.58).

3: Error messages that may appear when a PDO is processed.

4: Faults, that cannot be cleared by the user.

5: Operating errors/warnings.

The cat. 1 and 2 errors are indicated by blinking of the LED display in the front panel. (Fxx, xx =

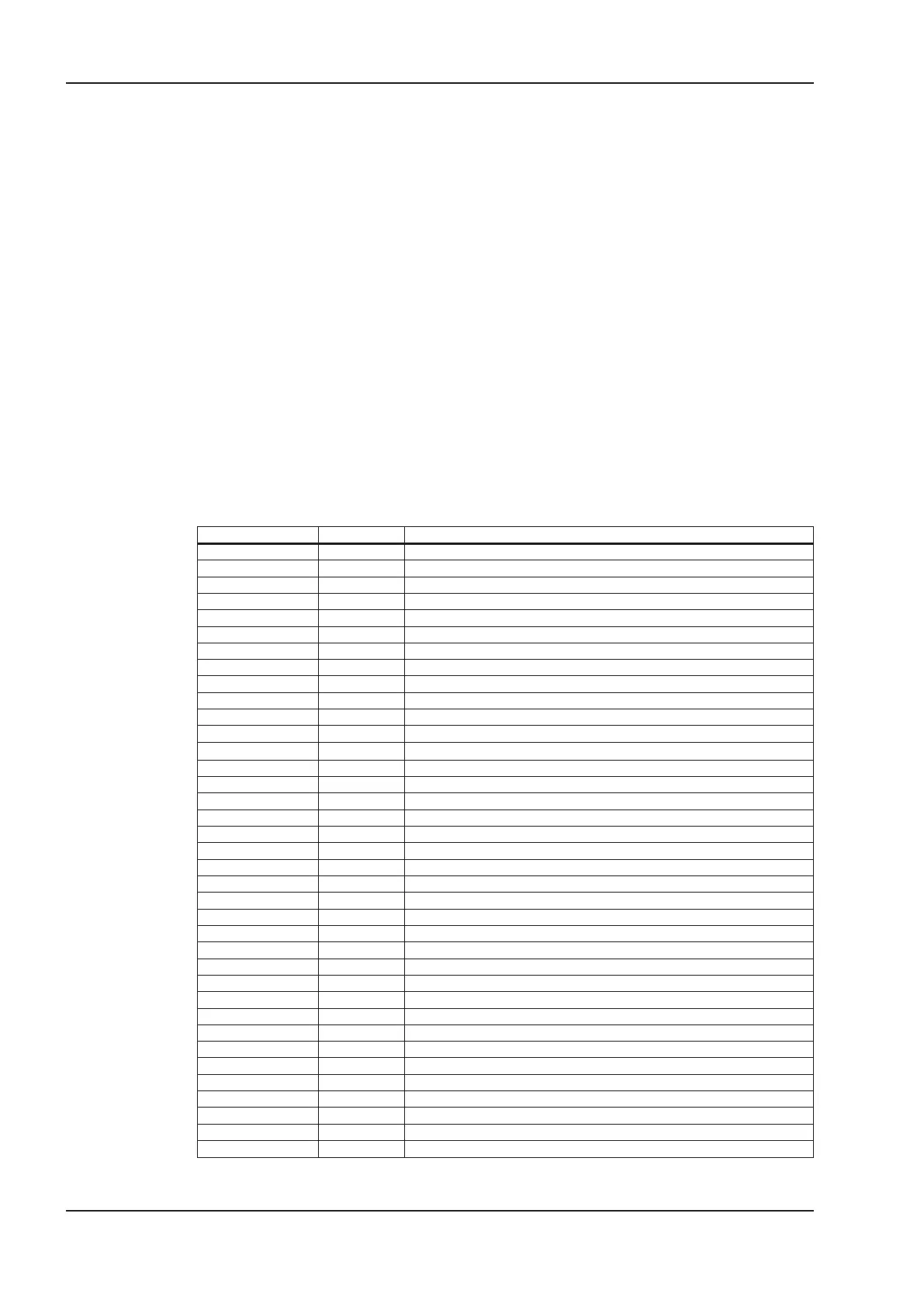

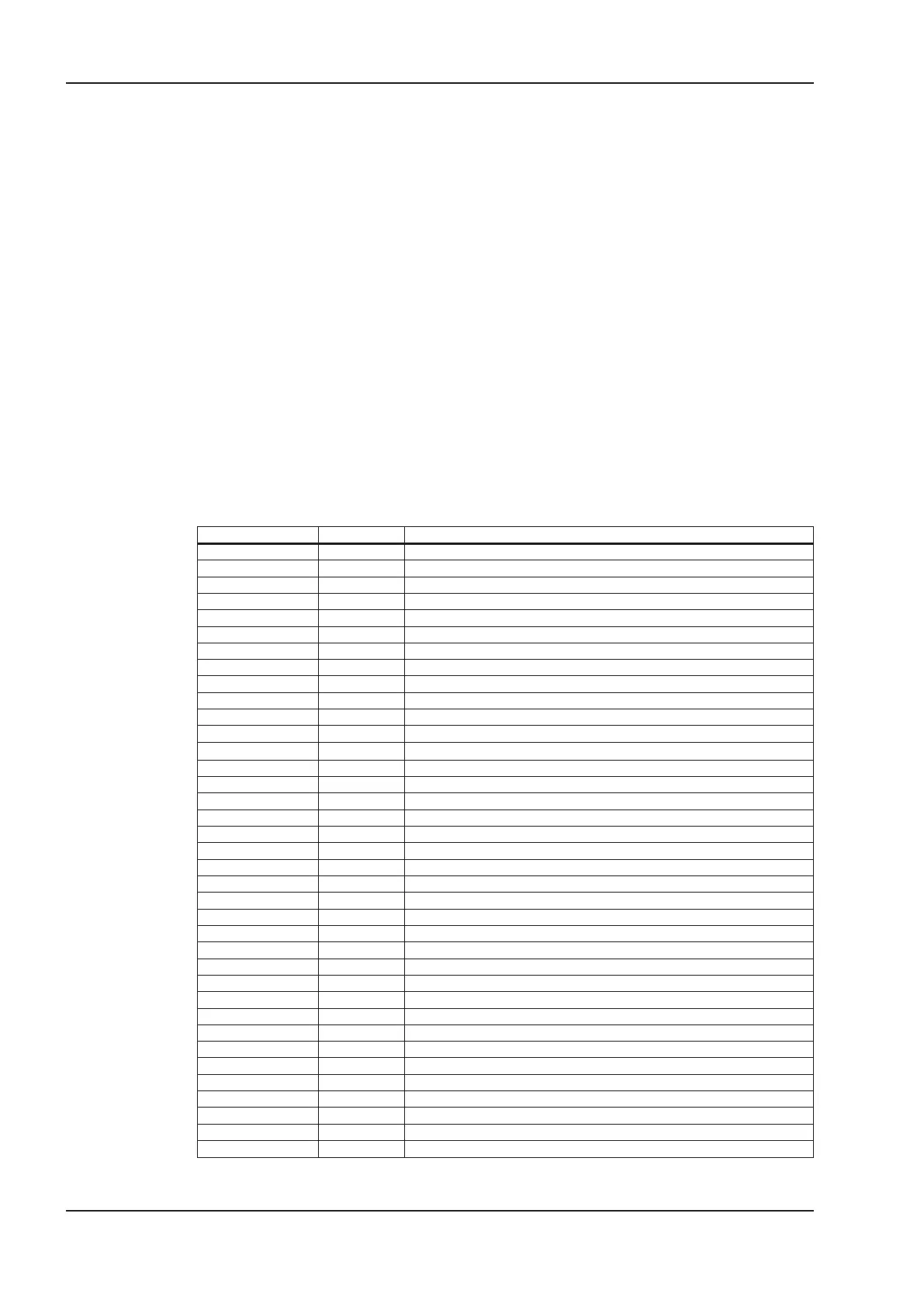

error number). The following table describes the various Error Codes:

Error Code Category Description

0000

h

— Error reset or no error (mandatory)

1000

h

— Generic error (mandatory)

1080

h

5 No BTB/RTO (status not ready for operation)

2330h 2 Error in ground connection (F22)

2380h 1 Error in motor connection (phase fault) (F12)

3100

h

2 No mains/line-BTB (F16)

3110

h

2 Overvoltage in DC-bus/DC-link (F02)

3120

h

2 Undervoltage in DC-bus/DC-link (F05)

3130

h

2 Supply line phase missing (with PMODE = 2) (F19)

4110

h

2 Ambient temperature too high (F13)

4210

h

1 Heat sink temperature too high (F01)

4310

h

1 Motor temperature too high (F06)

5111

h

1

Fault in ±15V auxiliary voltage (F07)

5380

h

1 Fault in A/D converter (F17)

5400

h

1 Fault in output stage (F14)

5420

h

1 Ballast (chopper) (F18)

5441

h

1 Operating error for AS-option (F27)

5530

h

1 Serial EEPROM (F09)

6320

h

3 Parameter error

7111

h

1 Braking error/fault (F11)

7122

h

1 Commutation error (F25)

7181

h

5 Could not enable S300/S700

7303

h

1 Feedback device error (F04)

7305h 1 Signal failure digital encoder input (F10)

8182

h

1 CAN bus off (F23)

8331

h

2I

2

t (torque fault, F15)

8480

h

2 Overspeed (F08)

8611

h

2 Lag/following error (n03/F03)

8681

h

5 Invalid motion task number

FF01

h

1 Serious exception error (F32)

FF02

h

3 Error in PDO elements

FF04

h

1 Slot error (F20)

FF05

h

1 Handling error (F21)

FF06

h

2 Warning display as error (F24)

FF07

h

2 Homing error (drove onto HW limit switch) (F26)

FF08

h

2 Sercos error (F29)

FF11

h

2 Emergency timeout failure(F30)

26 CANopen for S300/S700

CANopen Drive Profile 11/2018 Kollmorgen

Loading...

Loading...