2NC/2NF/2NG/2NN/3P7/3P8/3P9

1-4-68

(1) No image appears (entirely white).

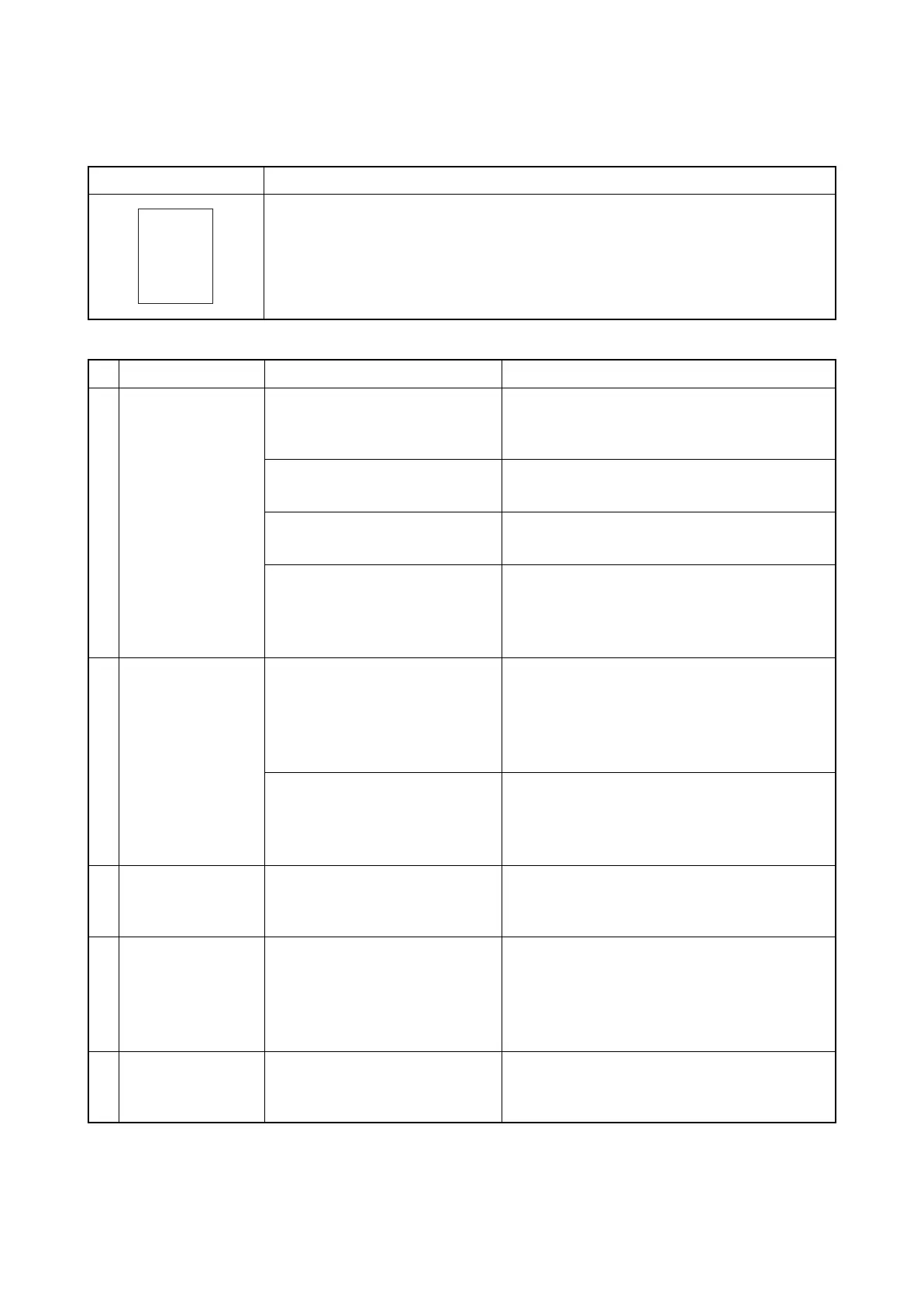

Print example Cause of trouble

1. No or defective developing bias output.

2. Failure of the rotation of the developing roller.

3. Defective transfer.

4. Laser is not dispersed from the laser scanner unit (LSU).

5. The drum does not rotate.

Defective part Check description Corrective Action

1

Developing unit Executing U089 to generate PGs

and check the following :

Check whether the developer

drive gear is damaged.

If the gear is damaged, replace the developer

unit.

Check the developing roller is

rotated by hand.

If the developer unit is in fault, replace the

developer unit. (see page 1-5-35)

Check contamination and defor-

mation on the terminals of devel-

oper unit or the high-voltage

PWB1.

If the connecting terminals are dirty, clean.

If the connecting terminals are deformed,

correct for a proper conduction.

2

High voltage PWB Check the connection of the con-

nector(s) and the high voltage

PWB. Or, verify conduction of

the wires.

Reinsert the connector if it its connection is

loose.

Replace the cable if it has no conduction.

High voltage PWB (YC 1) and main/engine

PWB (YC3)

Check if developing bias value at

its default by U140.

1. If the value obtaines by U140 does not

conform to the default value, reset it to the

default. (see page 1-3-51)

2. Replace the high-voltage PWB.

3

Transfer unit Check if the right cover is closed. If the right cover has not been closed,

check how the conveying guide is locked and

open the conveying guide once, then close.

4

Laser scanner unit

(LSU)

Check the connection of the con-

nectors.

Or, verify conduction of the

wires.

1. Reinsert the FFC wire if it its connection is

loose.

Replace the cable if it has no conduction.

2. Replace the LSU

(see page 1-5-27)

5

Main/Engine PWB A control signal is not derived

from the main/engine PWB.

Replace the main/enging PWB.

(see page 2-2-11)

Loading...

Loading...