General Maintenance 43

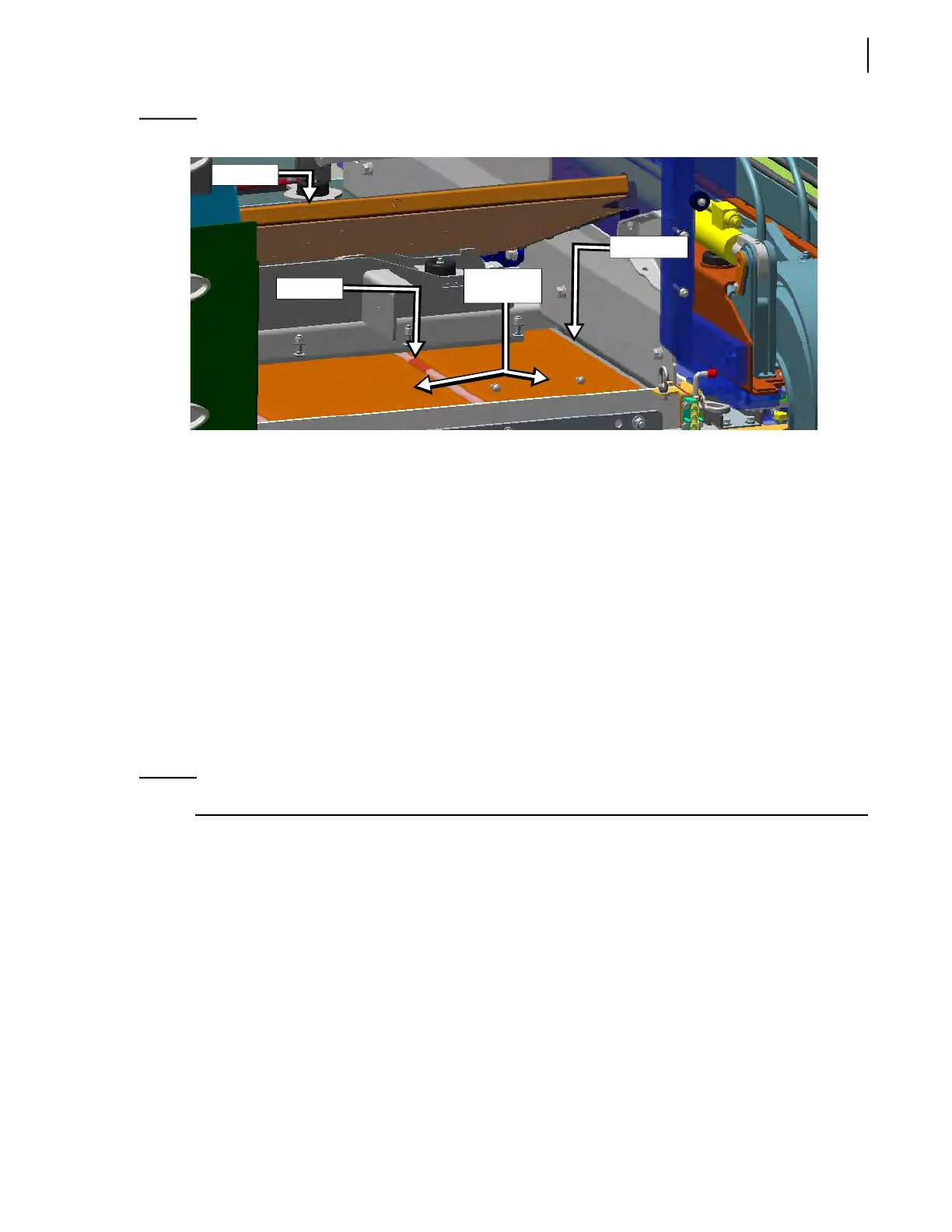

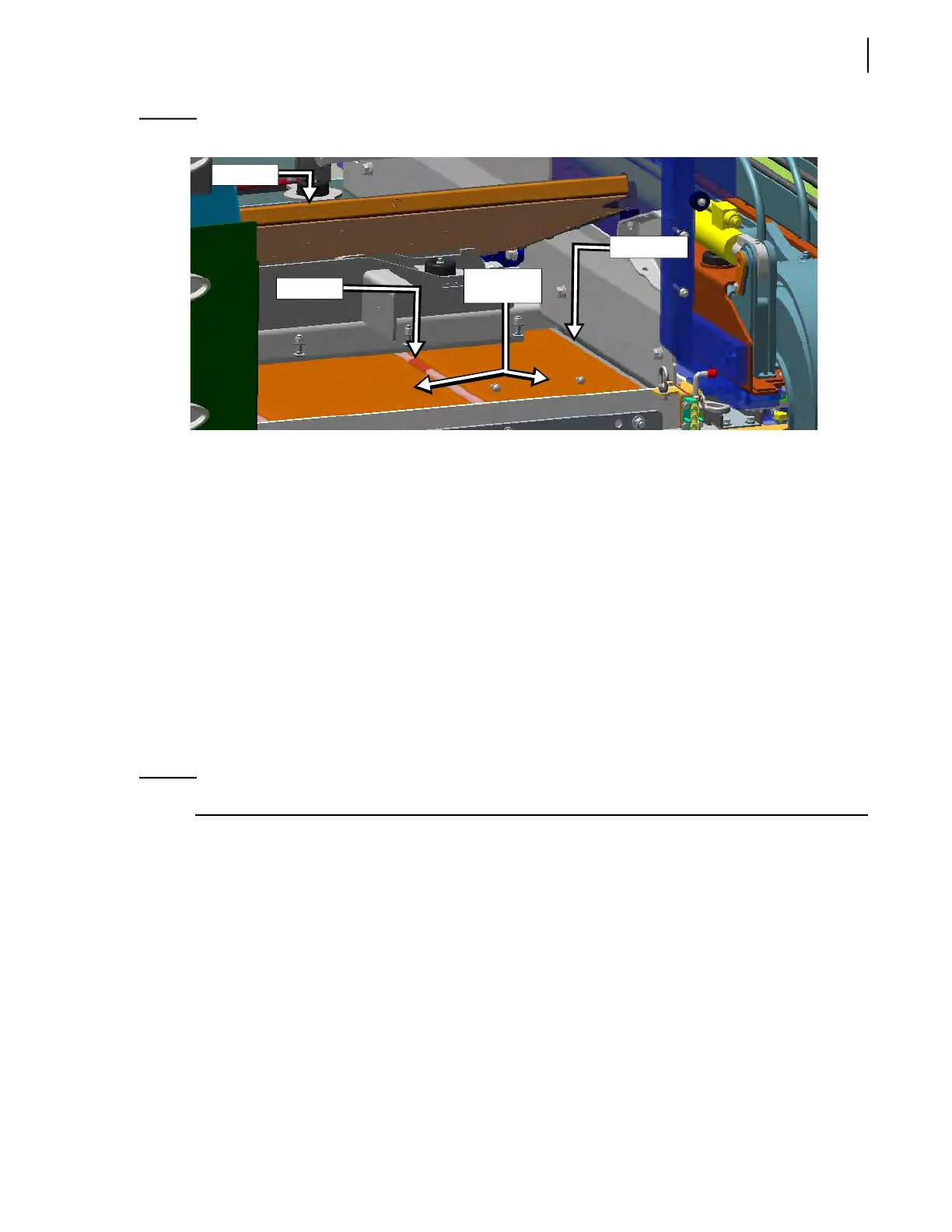

Figure 3-18

Extended packer

2. Inspect the scraper (nylon strip) at the bottom of the automated arm assembly (see Figure 3-18).

This nylon strip wipes out dirt every time the packer goes back and forth.

Replace this scraper before it is worn down to the top of its holding screws (see Lower Wear Pad

on page 165).

3. Visually inspect both packer side rails and rollers (see Figure 3-20).

If signs of premature wear are apparent, replace the faulty parts (see Sliding Shoes on page 127,

Follower Panels on page 179, and Rollers on page 190).

4. Check out for leaks on hydraulic hoses and tubes.

Tighten leaking connections and/or replace defective hoses.

5. Verify cylinder rods:

5 a. Make sure that cylinder rod ends are clear of debris.

5 b. Make sure that cylinder rods have no scratches that may cause the cylinder to leak oil.

Should you find oil leaks, the cylinder must be replaced immediately.

NOTE: During the warranty period, do not attempt to change cylinder seals and packing.

6. Check the packer for vertical and horizontal movements. See Testing for Excessive Wear on

page 128 for correct procedure.

If the packer shows vertical or horizontal movement, wear pads need to be replaced. Extensive

wear on the hopper floor also suggests that sliding shoes require immediate replacement (see

Sliding Shoes on page 127).

7. Verify packer panel for knocking noises.

Knocking noises indicate that the Extend proximity switch requires adjustment (see Adjusting

Packer Extend Proximity Switch on page 202). Proper adjustment is necessary to prevent cylinders

from bottoming out under pressure.

8. Make sure that hydraulic cylinders are not leaking internally (resulting in insufficient packing

power). For more information, see Detecting Cylinder Internal Leaks on page 285.

Hinge

Follower

panels

Scraper

Chute

Loading...

Loading...