Configuration

8200SHB01997-36

Influence PID controller When using a process control with frequency precontrol (C238 = -1-), the control factor is very

important.

-

The control factors is calculated from the difference of the values under C050 and C051.

-

The control factor determines the influence C074 of the PID controller.

-

The influence (C074)refers to f

dmax

(C011).

-

C074 influences the stability of the control circuit. It should be set to a value as lowas possible.

The influence C074 [%] is calculated as follows:

Influence [%]

C050 C051

C011

ô 100 %

Example

The influence is to be calculated for the following values:

C011 = 50 Hz, C050 = 53 Hz, C051 = 50 Hz

6%

53 Hz 50 Hz

50 Hz

ô 100 %

-

Set the influence so that the output of the process controller covers the calculated value in every

operating point.

- For this example (influence = 6 %) set for instance C074 = 10 %. This is a guide value and

includes tolerances which must always be considered.

-

If the influence (C074)is too high, the control circuit may become instable.

Additive influence of the process

controller

Conditions:

-

C051 = Positive actual value

-

C181 = Select positive setpoint

-

C238 = -1- (with frequency precontrol)

-

Potentiometer connections of the dancer

- End (E) = + 10 V

- Beginning (A) = GND

The direction of control action of the process controller output is added to the main setpoint.

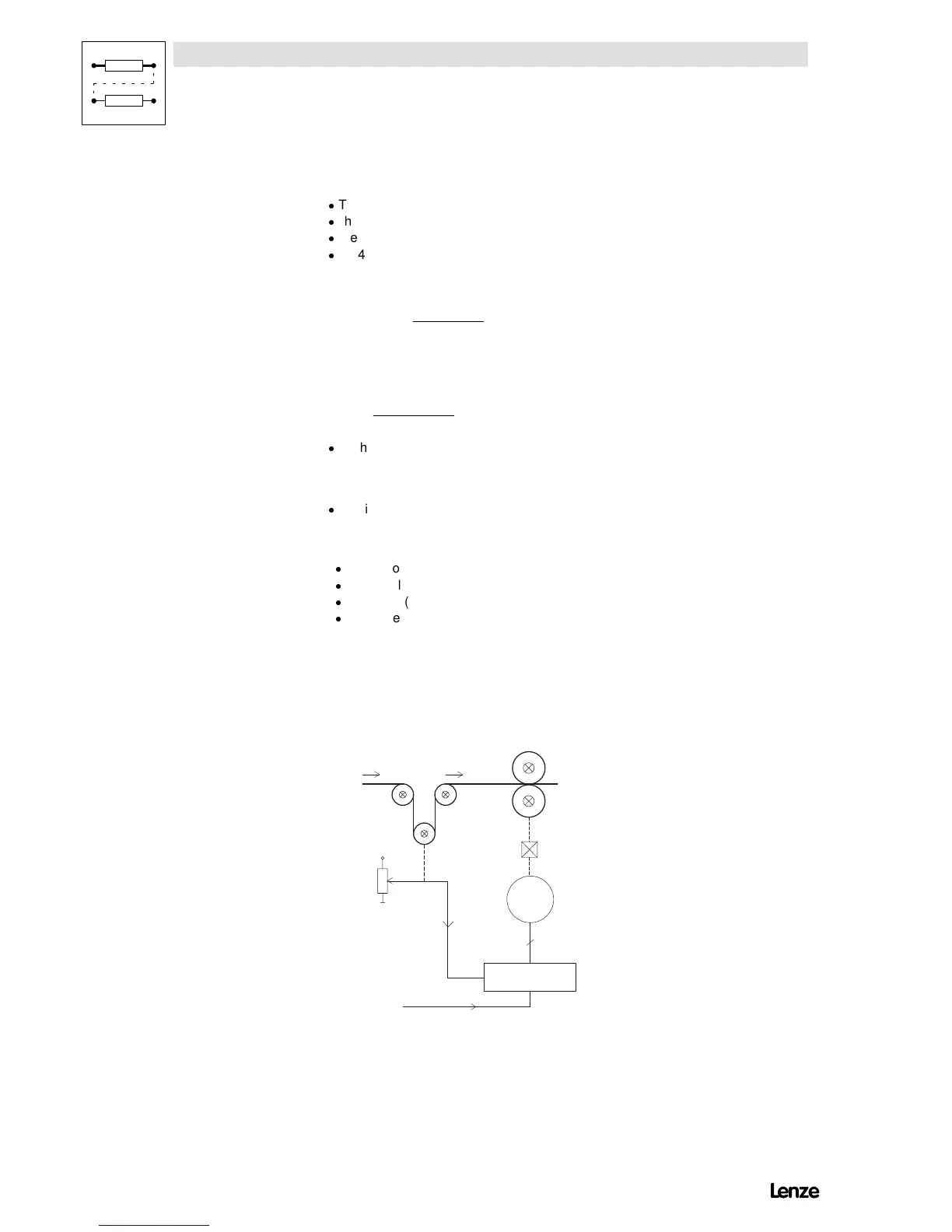

Example of a dancer control with additive influence

of the process controller

M

3~

82XX V20

3

V

T

A

+10 V

0 V ... 10 V

~V1

V1 V2

S

E

Function:

1.The dancer deflects to the bottom.

(V

T

decreases)

2.V2 increases.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...