Starting up

- 43 -

04.19 909.1709.9-05

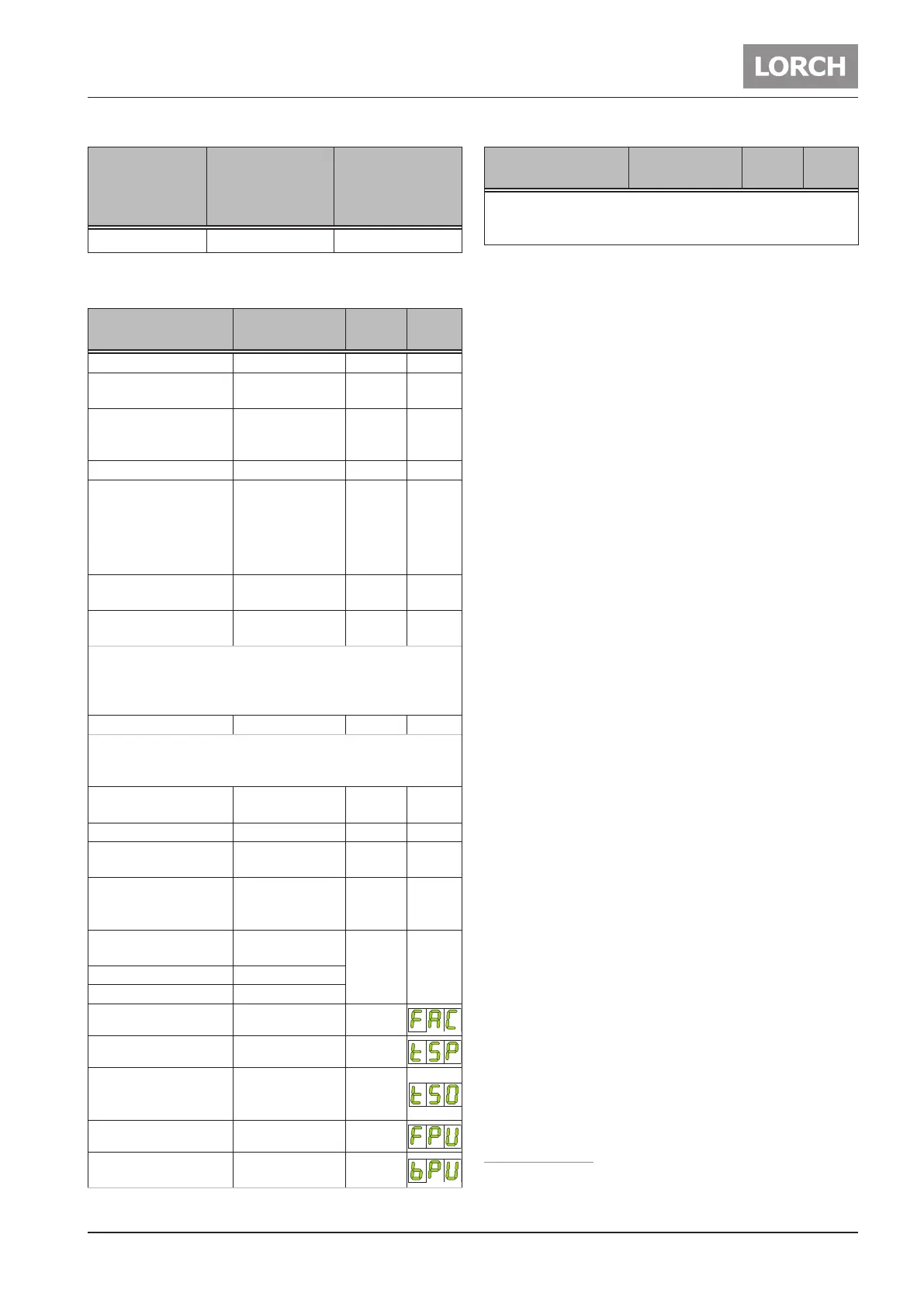

Electrode

diameter

[mm]

Recommended

current inten-

sity DC

[A]

Recommended

current inten-

sity AC

[A]

4,0 220 - 450 200 - 320*

*) Depending on the type of electrode and AC-Balance

parameter setting

Parameter Range

Factory

setting

LED/

Code

Gas pre-ow time 0,1 - 10 sec. 0,1 38

Start current IS

5 - 200 % of

main current

50 39

Start current time tS

(only for 2-stroke

mode)

0 - 20 sec. 0,1 40

Upslope 0 - 99 % 5 41

Main current I1

100 43

T 180 3 - 180 A

T 220 3 - 220 A

T 250 5 - 250 A

T 300 5 - 300 A

Second current I2

1 - 200 % of

main current

50 45

MACS-DC current

1, 3

1 - 200 % of

main current

50 45

Indicates the percentage ratio of the welding current

strength direct current (DC) to the main current I1.

If the value set is 50, the DC current strength is 50% of the

main current I1.

Downslope 0 - 500 % 20 46

A synchronisation takes place in the DC pulse operating

mode with feed or control The current reduction always

begins with I2 independent of the current status I1 or I2.

Final current IE

5 - 200 % of

main current

25 48

Final current time tE 0 - 20 sec. 0,2 49

Gas post-ow time

correction

20 - 500 % 100 51

AC-balance

1

10 - 90 %

positive welding

current

35 47

Tungsten electrode

diameter

2,4 42

T 180, T 220 1,0 - 3,2 mm

T 250, T 300 1,0 - 4,0 mm

AC-frequency

1

30 - 200 Hz 60

Spot welding time 0,01 - 10 sec. 1

Spot welding time Off

(only with interval spot

welding “On”)

0,09 - 60 sec. 1

Pulse frequency 0,2 - 2000 Hz 5

Pulse duty factor

1 - 99 % Main

current I1

50

Parameter Range

Factory

setting

LED/

Code

Indicates the percentage ratio between main current I1 and

auxiliary current I2. If the value set is 30, the ratio is 30 %

I1 to 70 % I2.

Tab. 3: Main parameters

The factory setting values are optimised thanks to auto-

matic parameters.

You can use these factory settings unchanged for most

welding jobs.

Further ne adjustment facilities can be found in Chapter

„14.3 Secondary parameters“ on page 44.

1)

Only for AC/DC

2)

Only in operating mode Electrode

3)

Only in operating mode TIG

Loading...

Loading...