Starting up

- 45 -

04.19 909.1709.9-05

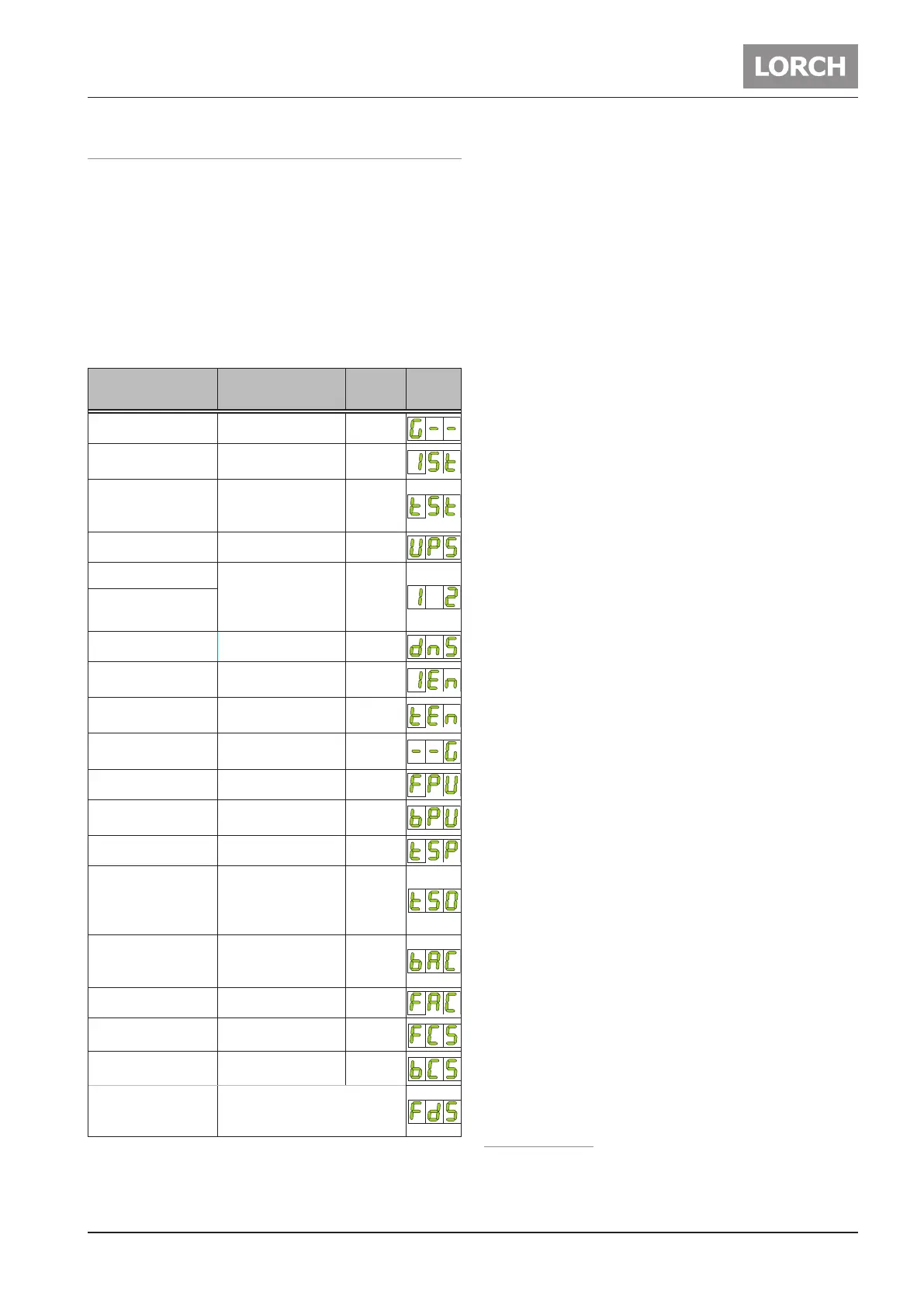

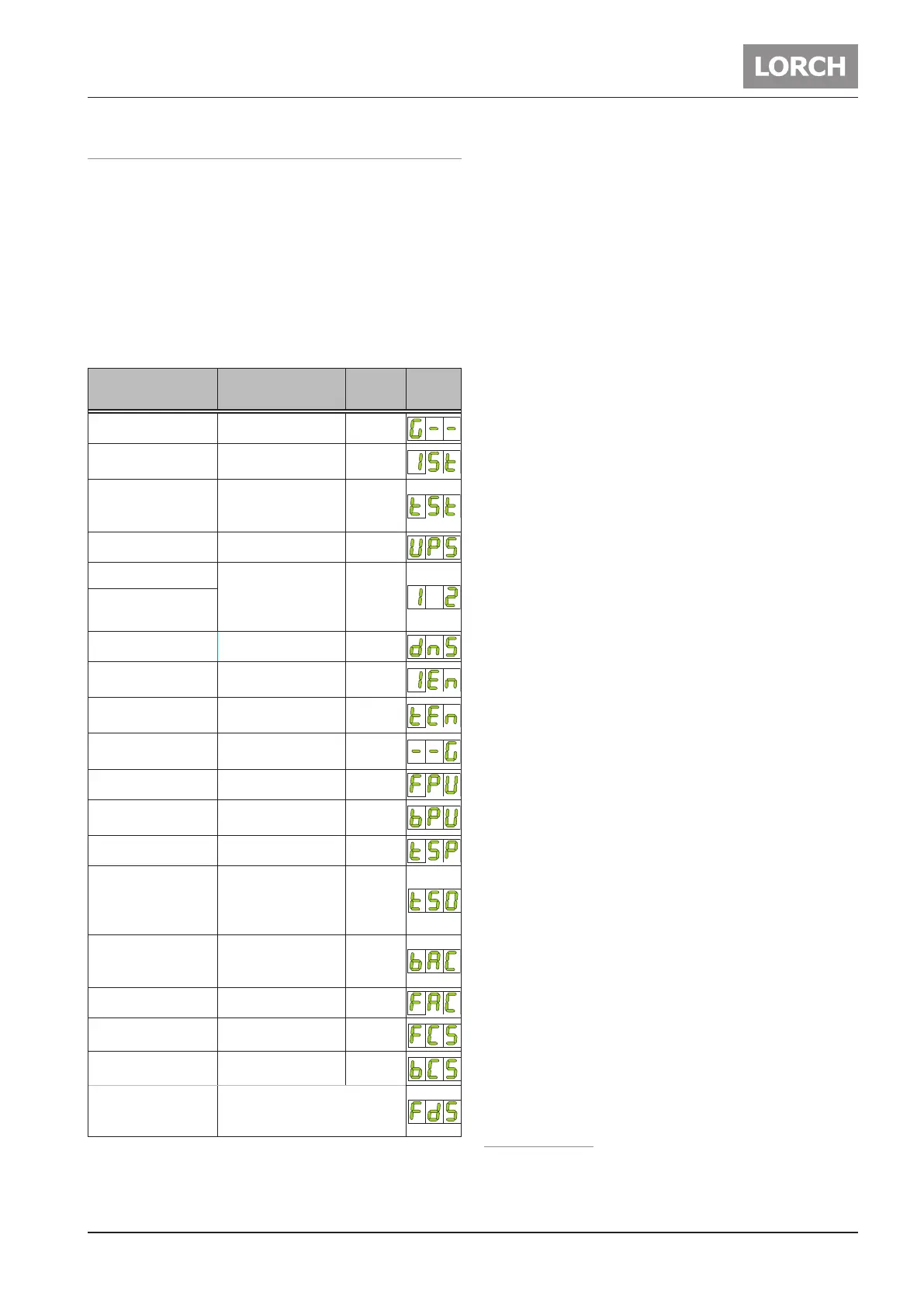

14.4 Powermaster parameters

All Powermaster torches of the i-LTG/i-LTW – serie have

two free programmable parameter spaces (PL3 and

PL4).

Select sub parameter PL3 or PL4.

9 In the 7-segment display (36) on the left side, code

PL3 or PL4 are indicated. In the 7-segment display

(35) on the right side, the code of the selected Pow-

ermaster Parameter is shown.

Different Powermaster parameters can be selected

with the turning knob 34.

Parameter Range

Factory

setting

Code

Gas pre-ow time 0,1 - 10 sec 0,1

Start current IS

5 - 200 % of main

current

50

Start current

time tS (only for

2-stroke mode)

0 - 20 sec. 0,1

Upslope 0 - 99 % 5

Second current I2

1 - 200 % of main

current

representation in

Amp.

50

MACS-DC

current

1, 3

Downslope 0 - 99 % 20

Final current IE

5 - 200 % of main

current

25

Final current time

tE

0 - 20 sec. 0,2

Gas post-ow time

correction

20 - 500 % 100

Pulse frequency 0,2 - 2000 Hz 5

Pulse duty factor

1 - 99 % Main cur-

rent I1

50

Spot welding time 0,01 - 10 sec. 1

Spot welding time

Off

(only with interval

spot welding “On”)

0,09 - 60 sec. 1

AC-balance

1

10 - 90 %

positive welding

current

35

AC-frequency

1

30 - 200 Hz 60

MACS-

frequency

1, 3

0,2 - 5 Hz 2

MACS-balance

1, 3

10 - 90 %

alternating current

60

wire feed speed 1

(only if FEED is

connected)

see wire feeder FEED

Tab. 5: Powermaster parameters

1)

Only for AC/DC

2)

Only in operating mode Electrode

3)

Only in operating mode TIG

4)

Only in operating mode Spot Welding

Loading...

Loading...