Starting up

- 42 -

04.19909.1709.9-05

14 Starting up

14.1 Electrode welding process

Use button 20 to select the electrode mode (LED

electrode 21 lights up).

Use the selection buttons 32 or 33 to select the pa-

rameter electrode diameter (LED 42 lights up).

Use knob 34 to set the desired electrode diameter.

Use the current mode selection button 27 to set the

desired current mode.

Use the selection buttons 32 or 33 to select the pa-

rameter main current I1 (LED 43 lights up).

Use the rotary knob 34 to set the desired current

intensity. If the current intensity does not match the

selected electrode diameter then the warning LED

lights 50 up. Nevertheless, it is possible to weld.

9 Your welding machine is now ready for use.

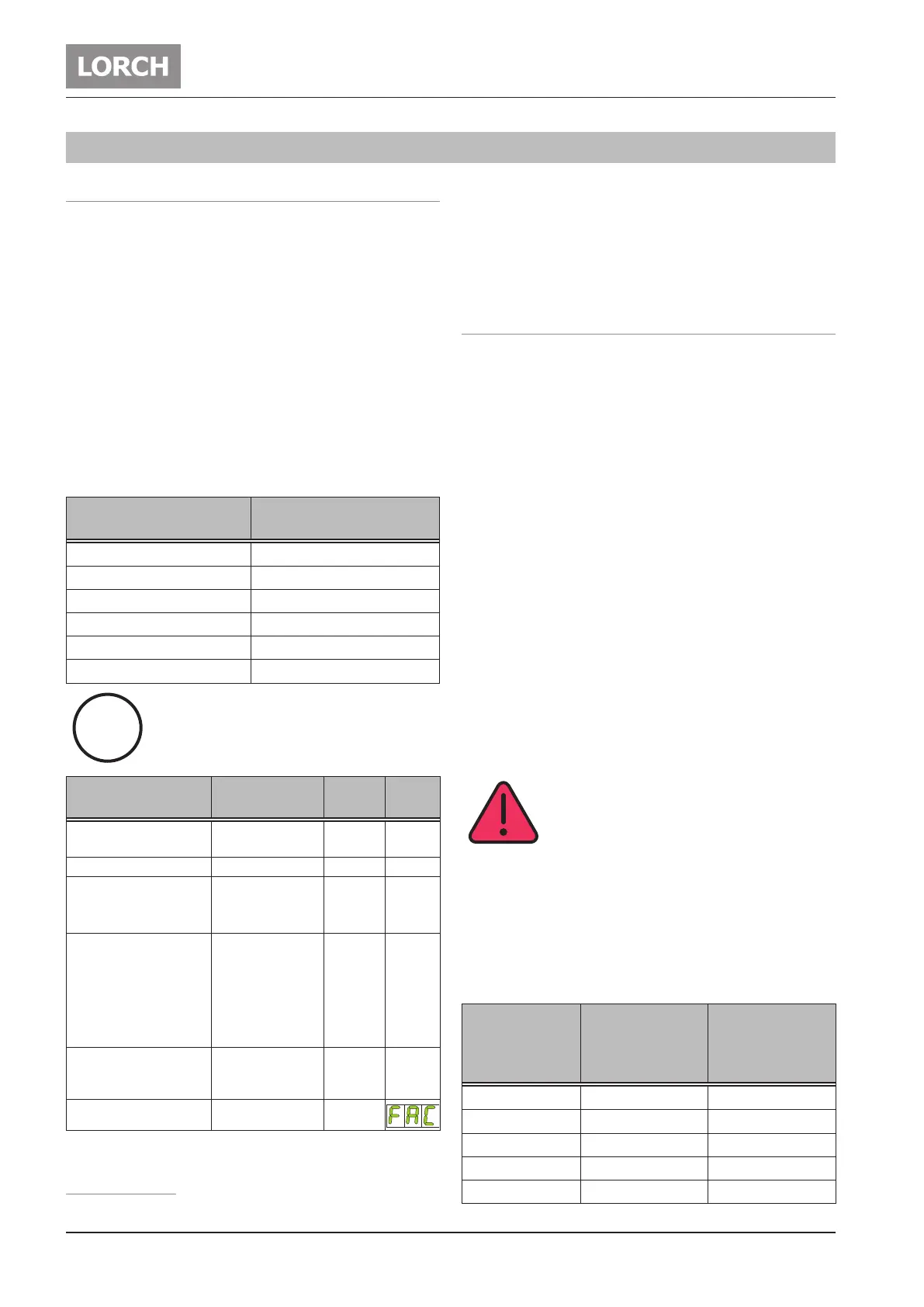

Electrode diameter [mm]

Recommended current

intensity [A]

1,5 20 - 40

2,0 35 - 60

2,5 45 - 100

3,2 75 - 140

4,0 130 - 190

5,0 180 - 260

Heed the electrode manufacturer’s instruc-

tions.

Parameter Range

Factory

setting

LED/

Code

Hotstart IS 5 - 200 %

of main current

125 39

Hotstart time tS 0 - 20 sec. 1 40

Electrode diameter

2,5 42T 180, T 220 1,5 - 4,0

T 250, T 300 1,5 - 5,0

Main current I1

100 43

T 180 10 - 150 A

T 220 AC/DC 10 - 170 A

T 220 DC 10 - 180 A

T 250 10 - 200 A

T 300 10 - 200 A

AC-balance

1

10 - 90 %

positive welding

current

35 47

AC-frequency

1

30 - 200 Hz 60

Tab. 2: Main parameters

1)

Only for AC/DC

The factory setting values are optimised thanks to auto-

matic parameters.

You can use these factory settings unchanged for most

welding jobs.

Further ne adjustment facilities can be found in Chapter

„14.3 Secondary parameters“ on page 44.

14.2 TIG welding process

Select the desired mode with button 20.

– 2-stroke mode (LED 26 lights up).

– 4-stroke mode (LED 25 lights up).

– Spots mode (LED 23 lights up, only for 2-stroke).

– 2-stroke pulse mode (LED 22 and LED 26 light

up).

– 4-stroke pulse mode (LED 22 and LED 25 light

up).

Use the selection buttons 32 or 33 to select the pa-

rameter electrode diameter (LED 42 lights up).

Use knob 34 to set the desired electrode diameter.

Use the current mode selection button 27 to set the

desired current mode.

Use the selection buttons 32 or 33 to select the pa-

rameter main current I1 (LED 43 lights up).

Use the rotary knob 34 to set the desired current in-

tensity. If the current intensity is not appropriate for

the selected tungsten electrode diameter, LED 50

lights up. Nevertheless, it is possible to weld.

9 Your welding machine is now ready for use.

HF ignition

Danger due to electric shock!

If function HF-ignition (31) is selected,

a high ignition voltage is present at the

torch.

Never touch the welding electrode or parts

conducting welding current when the de-

vice is switched on.

HF ignition is a contactless ignition brought about by

high-voltage impulses.

Using the current type button, select 27 HF ignition

(LED HF 31 lights up).

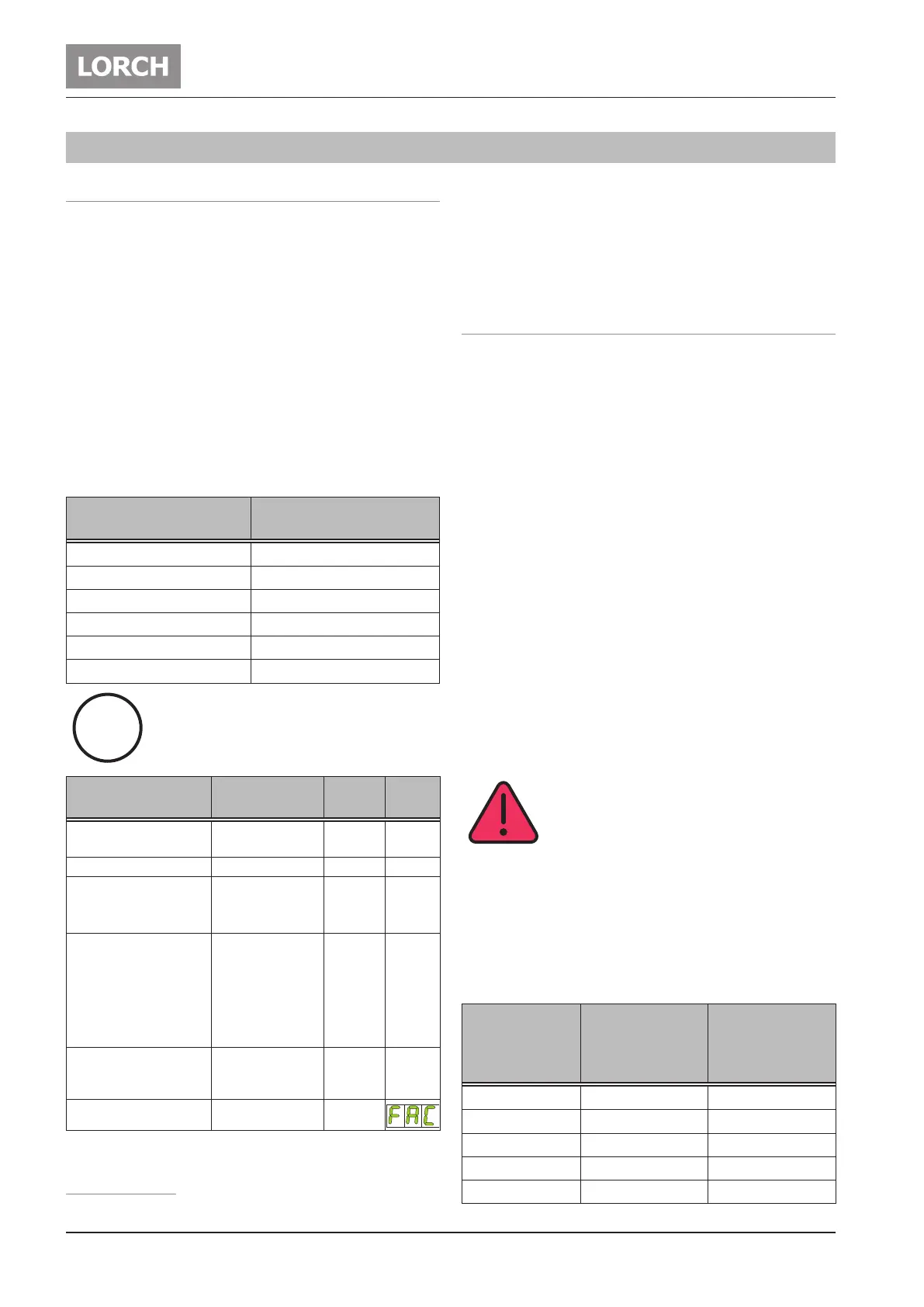

Electrode

diameter

[mm]

Recommended

current inten-

sity DC

[A]

Recommended

current inten-

sity AC

[A]

1,0 3 - 40 5 - 30*

1,6 15 - 130 20 - 90*

2,0 45 - 180 45 - 135*

2,4 70 - 240 70 - 180*

3,2 140 - 320 130 - 250*

i

Loading...

Loading...