Starting up

- 46 -

04.19909.1709.9-05

14.5 User-specicmenu

Switch off the equipment at the main switch 10.

Press the selection button on the left 32 and keep it

depressed.

Switch on the equipment at the main switch 10

9 The user-specic menu is activated. The menu item

is shown in the 7-segment display 36.

9 The set value is shown in the 7-segment display 35.

Press the selection button 32 or 33 to switch among

the menu items.

Turn the control dial 34 to change the set value.

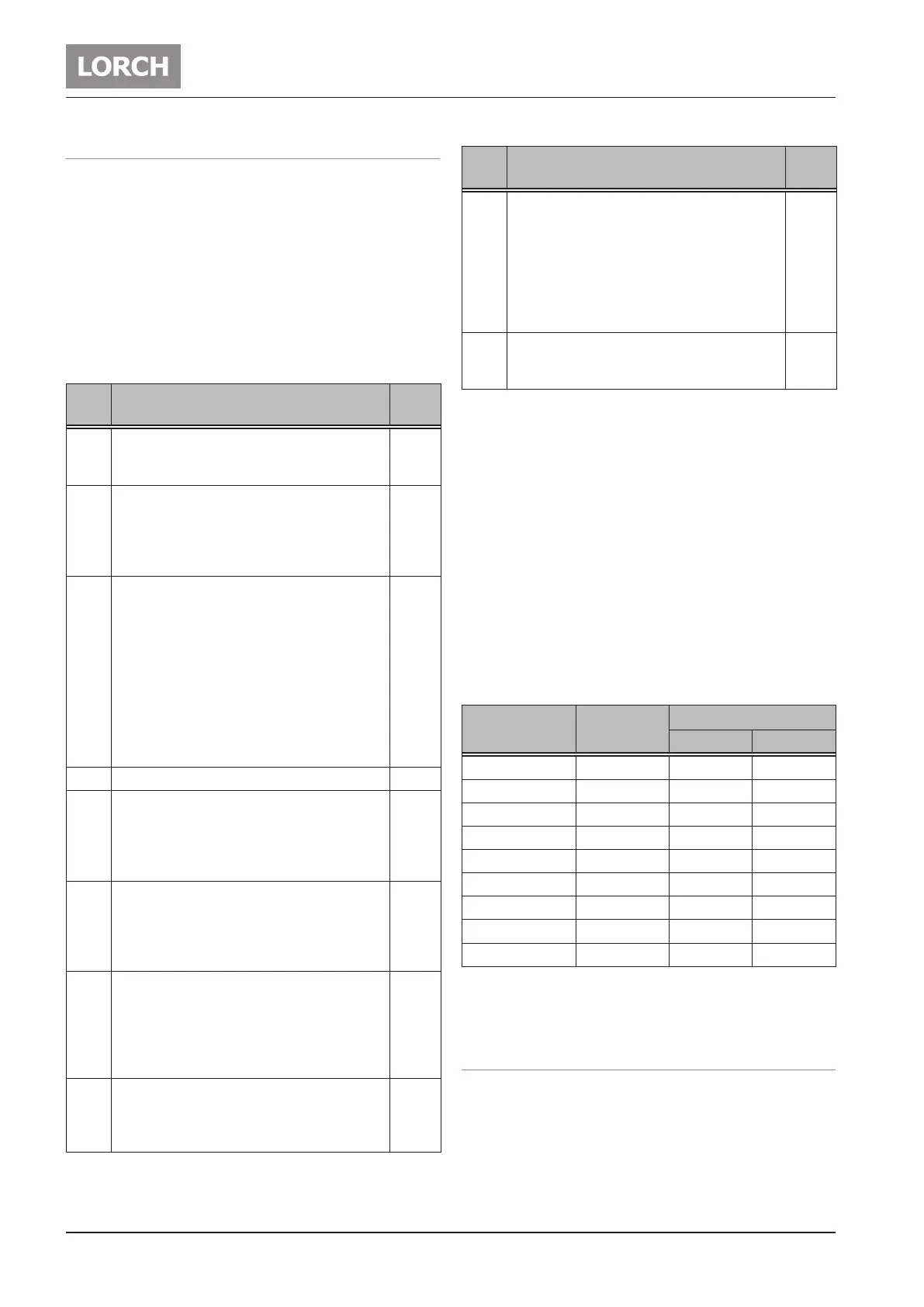

Menu

no.

Menu item

Setting

values

C00 Display and adjustment of the torch-ID.

See „Adjustment of the torch-ID“ on page

46.

9...45

C01 Welding current limit for up/down torch.

When the welding current limit is switched

to “On”, the welding current on the up/down

torch cannot be set higher than pre-select-

ed on the control terminal.

On-Off

C02 Deactivation of the error message E05-00

(water pump) and of the water cooling unit

by LorchNet.

If the deactivation is switched “on”, the

error message E05-00 (water pump) is no

longer displayed.

Also the water cooling unit is not switched

on by LorchNet.

Practical, e.g. for the use of an automatic

torch without plug or a cooling unit without

LorchNet.

On-Off

C03 Activation of the orbital welding mode. On-Off

C04 ON: at short circuit the welding current

don’t increase the adjusted welding current

shown in the display (set value).

Off: at short circuit the welding current is

increased on minimum 60 A.

On-Off

C05 ON: by quick pressing of torch button 1

(start / stop) the 2nd torch button is simu-

lated.

(Second current on / off). Useful e.g. for

torches with one button only.

On-Off

C06 ON: the current decrease (downslope) will

be - as adjusted – conducted, also if the

torch button is released (4th tact).

Off: at earlier release of the torch button

(4th tact) the current decrease (downslope)

is interrupted.

On-Off

C07 On: PE conductor monitoring activated

Off: PE conductor monitoring deactivated

the PE conductor monitoring is an optional

available feature

On-Off

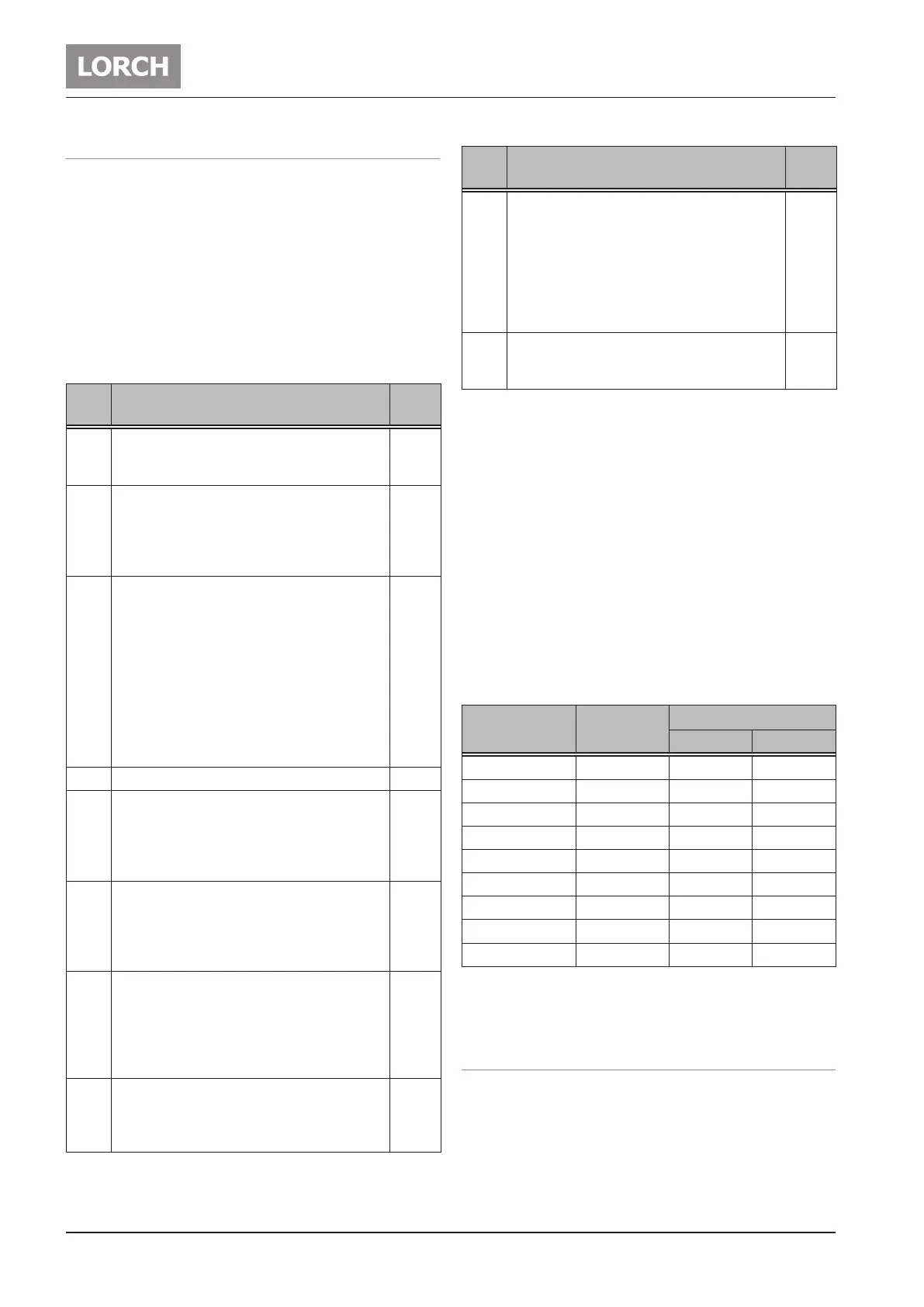

Menu

no.

Menu item

Setting

values

C08 Off: Using a foot remote control, the mini-

mum current (independent from the adjust-

ed welding current) in the TIG mode / AC at

electrode-Ø 1,0...2,0 mm = 10 Amps

electrode -Ø 2,4 mm = 15 Amps

electrode -Ø 3,2 mm = 20 Amps

On: the increased minimum current in the

TIG-mode / AC is deactivated

On-Off

C10 Welding current limit

0 = Off

I1

Min

...I1

Max

= On

0,

I1

Min

...

I1

Max

Tab. 6: User-specic menu

Switch the equipment off at the main switch 10 to

transfer the settings from the user-specic menu.

Adjustment of the torch-ID

Every torch of the i-LTG/i-LTW-series has an own torch-

ID. This ID is related to the stress limits of the torch. If

the torch protection is activated (sub-parameter “tPr” =

on) in the TIG-mode, only a welding current according to

the maximum torch limit can be adjusted at the welding

machine.

The adjustment of the torch –ID is necessary for e.g.

if the torch pc-board was changed.

Select in the user specic menu code-no. C00

Adjust the required torch-ID at the turning knob 34,

according to the torch-ID-chart.

Type of torch Torch-ID

Stress limits

DC AC

i-LTG 900 9 125 A 80 A

i-LTG 1700 17 150 A 120 A

i-LTG 2600 26 200 A 160 A

i-LTG 2800 28 300 A 250 A

i-LTW 3000 30 320 A 220 A

i-LTW 1800 18 350 A 250 A

i-LTW 1800sc 19 400 A 320 A

i-LTW 2000 20 220 A 165 A

i-LTW 4500 45 450 A 360 A

Tab. 7: Torch-ID

Press button „Save 58“ to save.

9 The adjusted torch-ID is transferred to the torch.

14.6 Other welding processes

MACS

1, 3

With the MACS (Modulated AC system) welding proce-

dure, the welding current is pulsed with alternating and

direct current.

Select the desired mode with button 20.

Loading...

Loading...