3-107

4.2 What TO DO WITH TWISTED WINCH WIRE ROPE

Be sure to wear a pair of thick leather working gloves when handling wire ropes.

CAUTION

Change the hooking direction of the wire rope (inverse the hook block side and winch drum

side) from time to time to extend the life of the wire rope.

When the wire rope gets twisted, straighten the twist with the

following procedure.

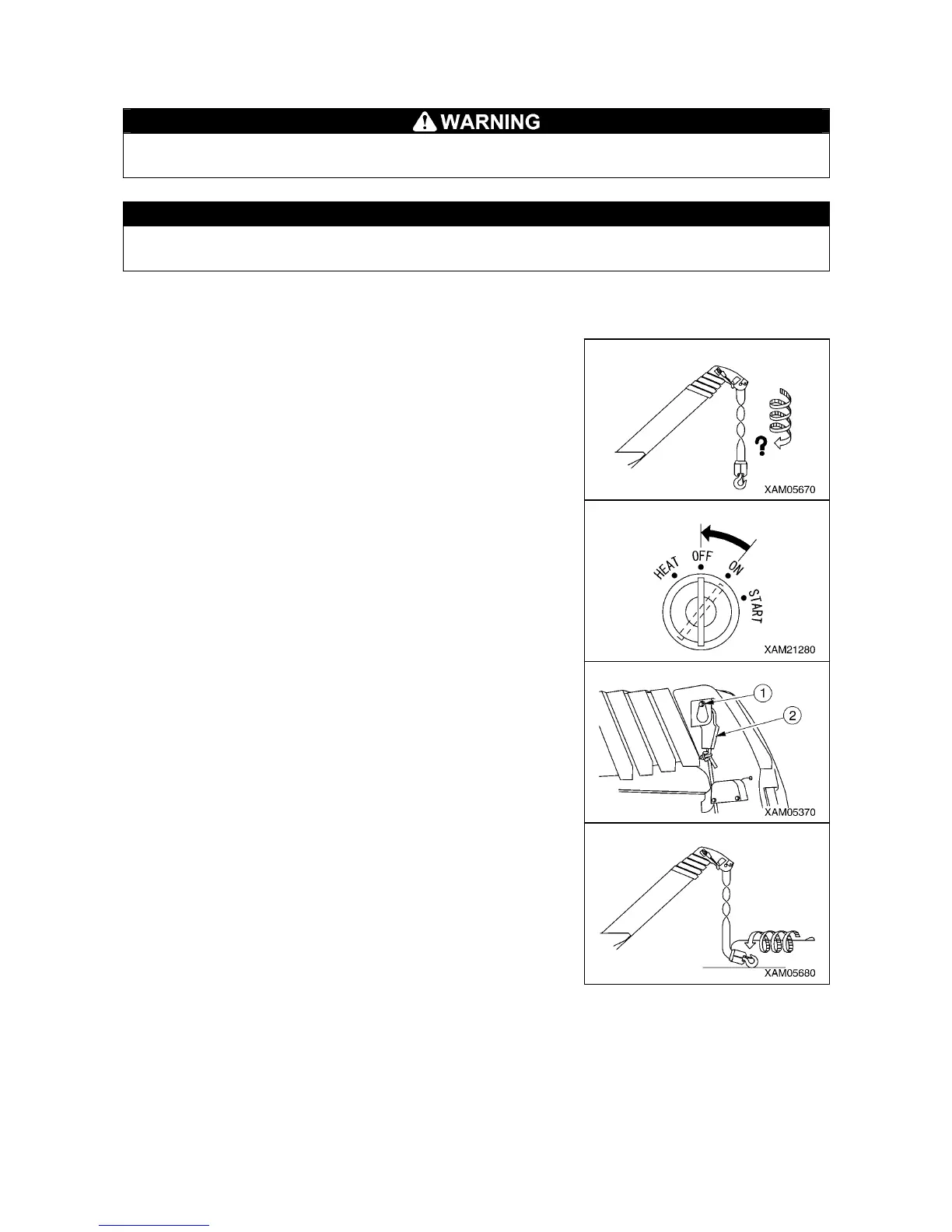

1. With the hook in normal condition, check the twisting direction

and how many times the rope is twisted.

2. Operate the winch lever to “DOWN” (push forward) side to lower

the hook block onto the ground.

If the hook cannot be lowered, operate the boom derricking lever

to the “LOWER” (push forward) side to lower the boom or

operate the boom telescoping lever to the “RETRACT” (pull

toward you) side to retract the boom to lower the boom.

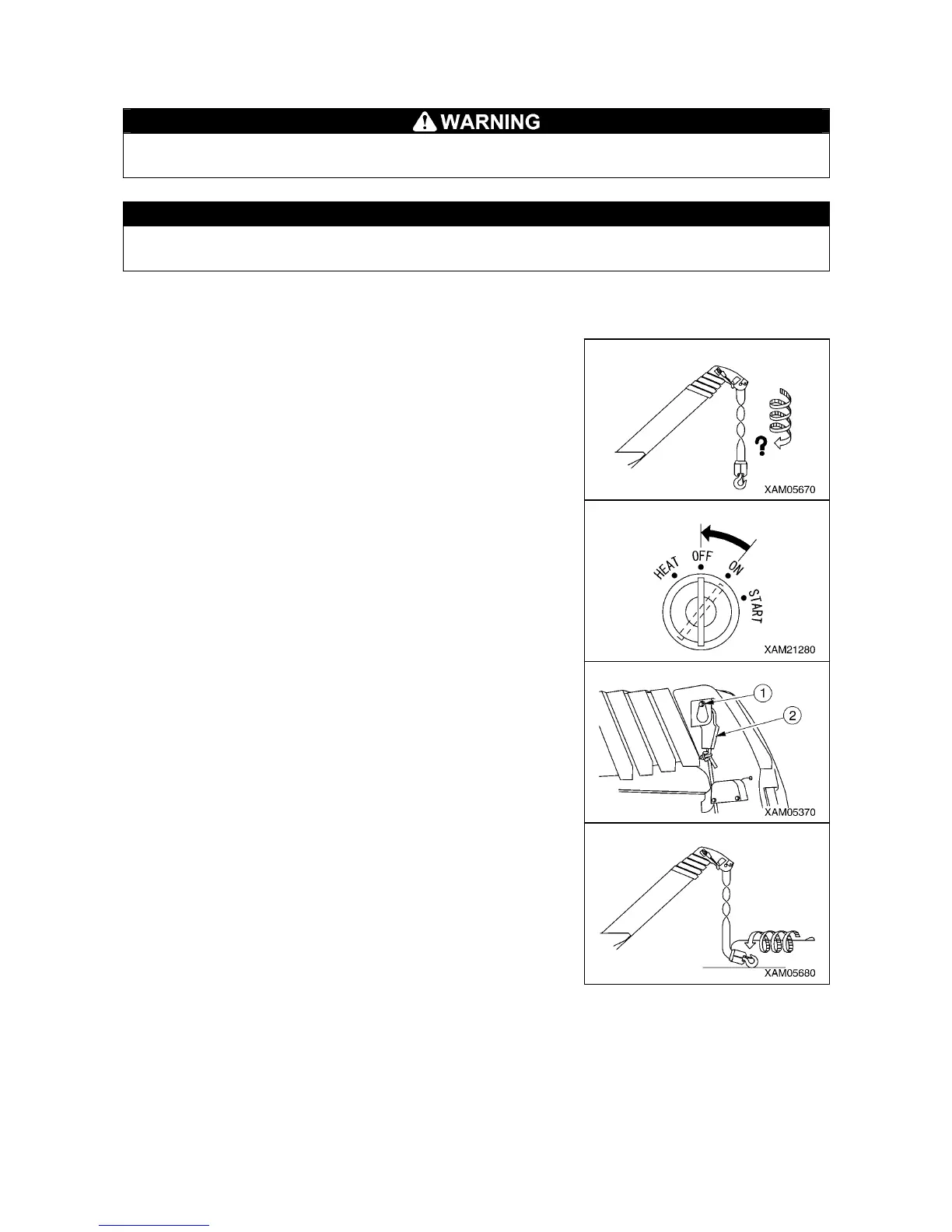

3. Turn the starter switch to the “OFF” position to stop the engine.

4. Remove the wedge socket pin securing bolt (1) to remove the

wedge socket (2).

5. Force to twist the end of the wire for “n” (number of wire falls)

times of the number hook is twisted for in the opposite direction

from the direction the hook block is twisted to and which you

checked in the step 1 (opposite direction from the one the wire

rope tries to go back to naturally when you release your hand

from the wedge socket) and install the wire rope.

6. Start the engine and operate the boom derricking lever to

the ”RAISE” (pull toward you) side to increase the boom angle to

its maximum.

7. Operate the boom telescoping lever to the “EXTEND” (push

forward) side to extend the boom to its maximum.

8. Operate the winch lever to repeat raising/lowering the hook

block for several times.

9. Tidily spool up the wire rope into the winch drum with some

tension applied to the rope.

10. Repeat the above procedure until the hook is no more twisted.

If the wire rope is still twisted after performing the procedure above,

change with a new wire rope.

Loading...

Loading...