7-22

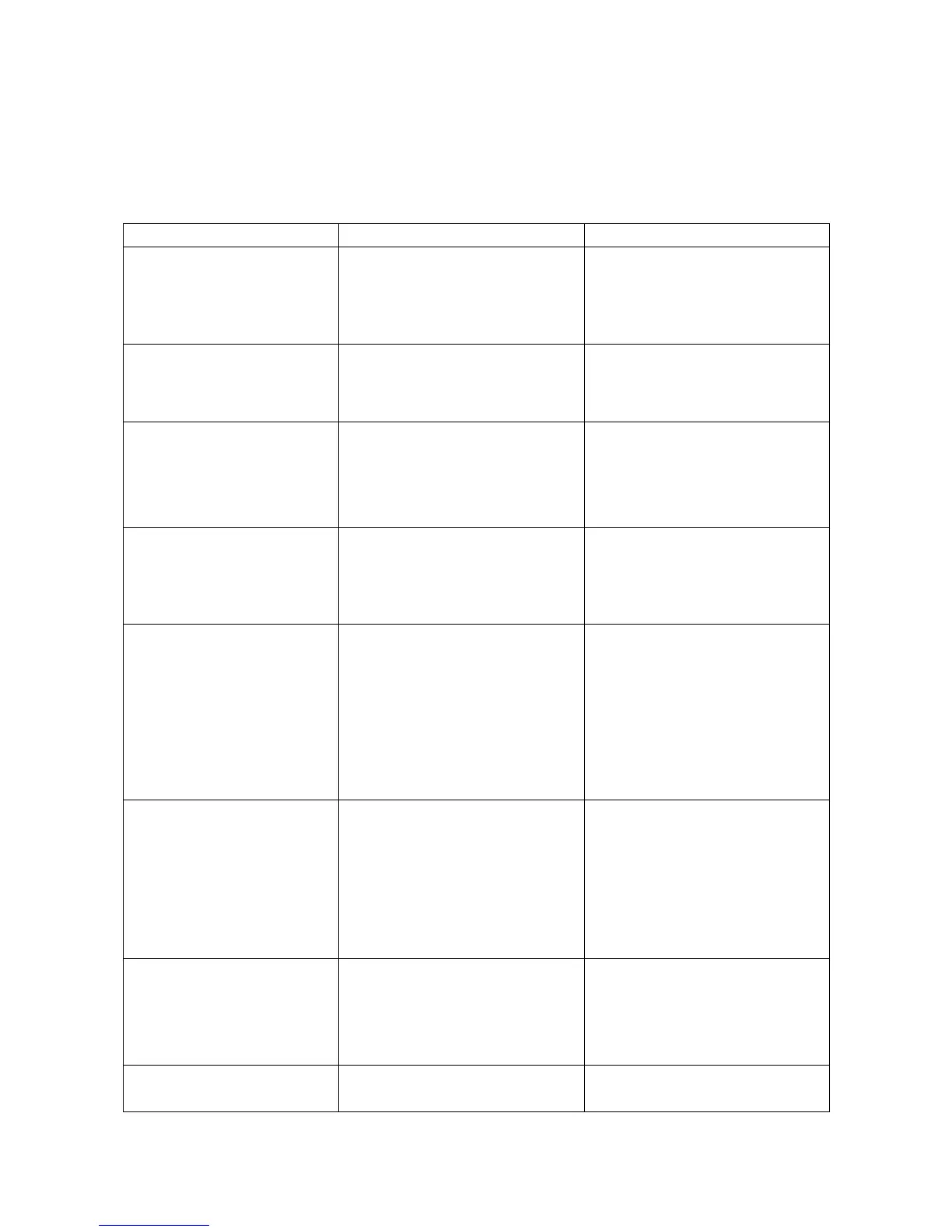

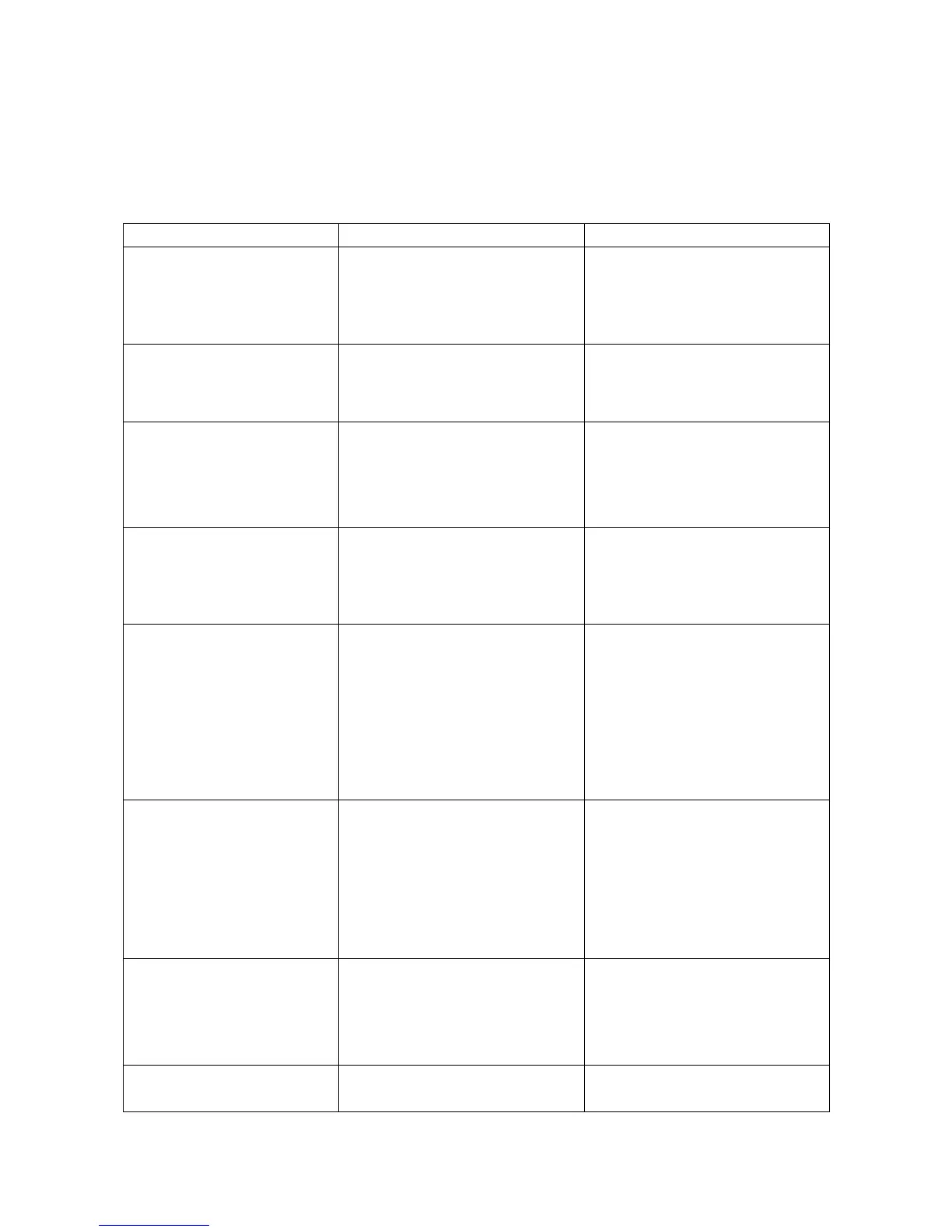

6. ELECTRIC MOTOR TROUBLESHOOTING

• Make sure that you contact us or our sales service agency for the actions indicated in parentheses in the

Actions field.

• Ask our sales service agency for repair if you suspect other abnormality or causes than those given

below.

Abnormal Phenomenon Major Cause(s) Actions

The motor remains off despite

the switch being turned to the

“START” position.

• Improper wiring and power supply

error

• The Inverter unit breakers: OFF

• A break in stator winding

• Check wiring, see “Engine &

Electric Motor Spec. 4. Operation”.

• Turn ON the breakers.

(• Inspection, repair, replacement)

(• Inspection, repair, replacement)

The motor comes to a stop

during use.

• Inverter unit error

(Red lamp: ON)

• Failure in the Inverter unit

• Failure in the power unit

• Check the power supply source

(voltage and phase interruption).

(• Inspection, repair, replacement)

(• Inspection, repair, replacement)

The power output of the motor

reaches zero or undergoes

gradual decrease.

• Phase interruption in the power

source of power supply equipment

• Slack in motor wiring

• Check the power source of power

supply equipment (voltage and

phase interruption).

• Inspect connection with the motor

Terminal block .

(• Inspection, repair, replacement)

The cabtyre cable rises in

temperature.

• Considerable voltage drop

• Ensure that the power supply

voltage of power supply equipment

is at a specified value.

• Replace the cabtyre cable with

one adhering to specifications.

An abnormal noise and

vibration are present in the

power unit during operation.

• A break in motor winding

• Looseness in the motor and pump

fixing bolt

• Looseness in the coupling fixing

bolt

• Impurities on the coupling

• Clogging in the hydraulic oil tank

strainer and element

• Inspect the motor Terminal block .

(• Inspection, repair, replacement)

• Perform inspection, repair, and

cleaning. See “Engine & Electric

Motor Spec. 4. Operation" .

(• Replacement)

• Clean and replace the strainer

and element according to periodic

inspection.

The power unit rises in

temperature during operation.

• High ambient temperature

• Ill-ventilated

• Considerable voltage drop

• Overload

• High number of starts

• Use the power unit in environment

compliant with specifications.

• Perform inspection and cleaning,

See “Engine & Electric Motor

Specifications 4. Operation".

• Replace the cabtyre cable with

one adhering to specifications.

• Reduce loads.

• Reduce the number of starts.

The leak detector of the

Inverter unit main breaker is

tripped.

• High humidity

• Presence of water droplets

• Ill-grounded

• A break in stator winding

• Use the leak detector in

environment compliant with

specifications.

• Attach the cover properly.

• Adhere to ground standards.

(• Inspection, repair, replacement)

The trouble lamp (red) of the

Inverter unit comes on.

• Failure in the Inverter unit (• Inspection, repair, replacement)

Loading...

Loading...