3-120

9.2 MACHINE BODY

• Make sure that you contact us or our sales service agency for the actions indicated in parentheses in the

Actions field.

• Ask our sales service agency for repair if you suspect other abnormality or causes than those given

below.

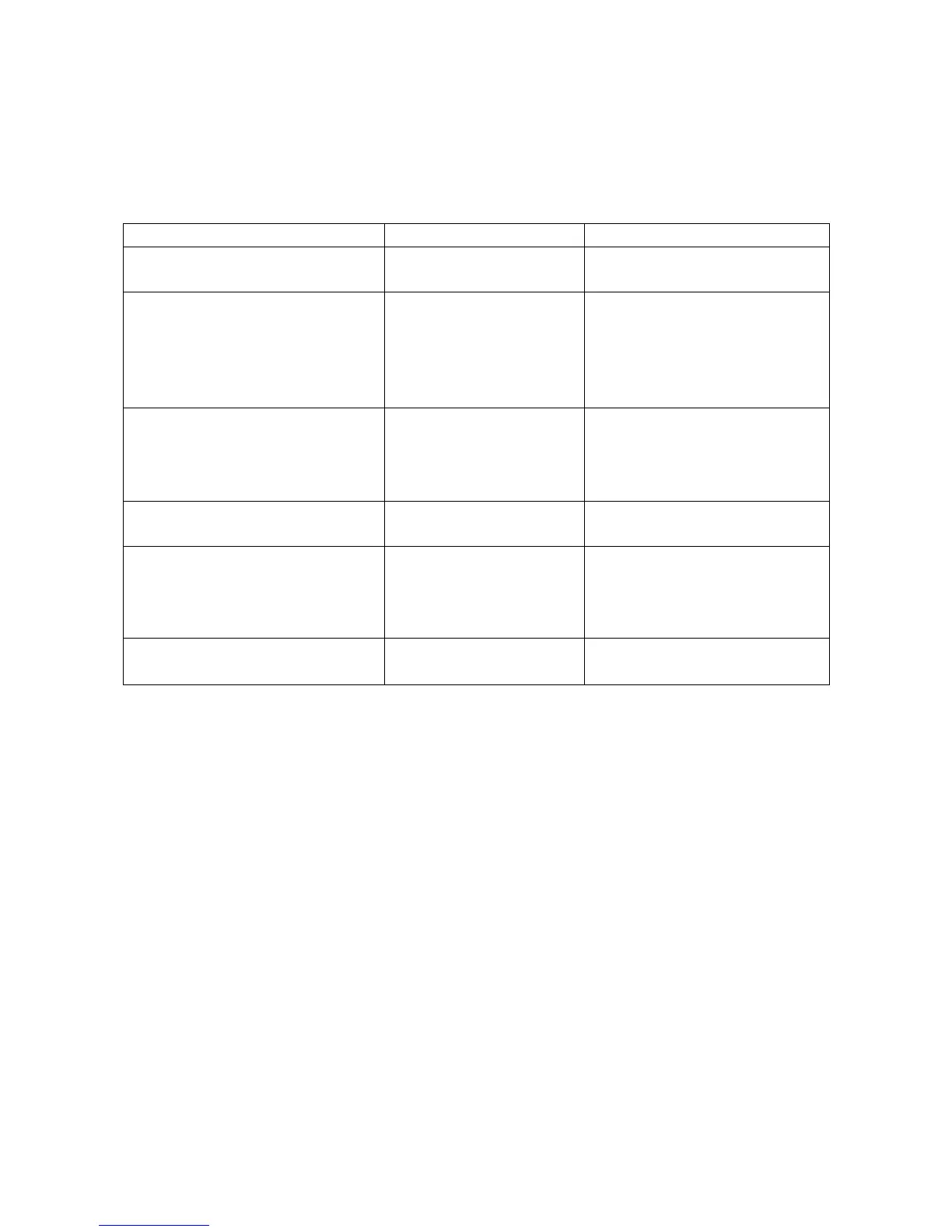

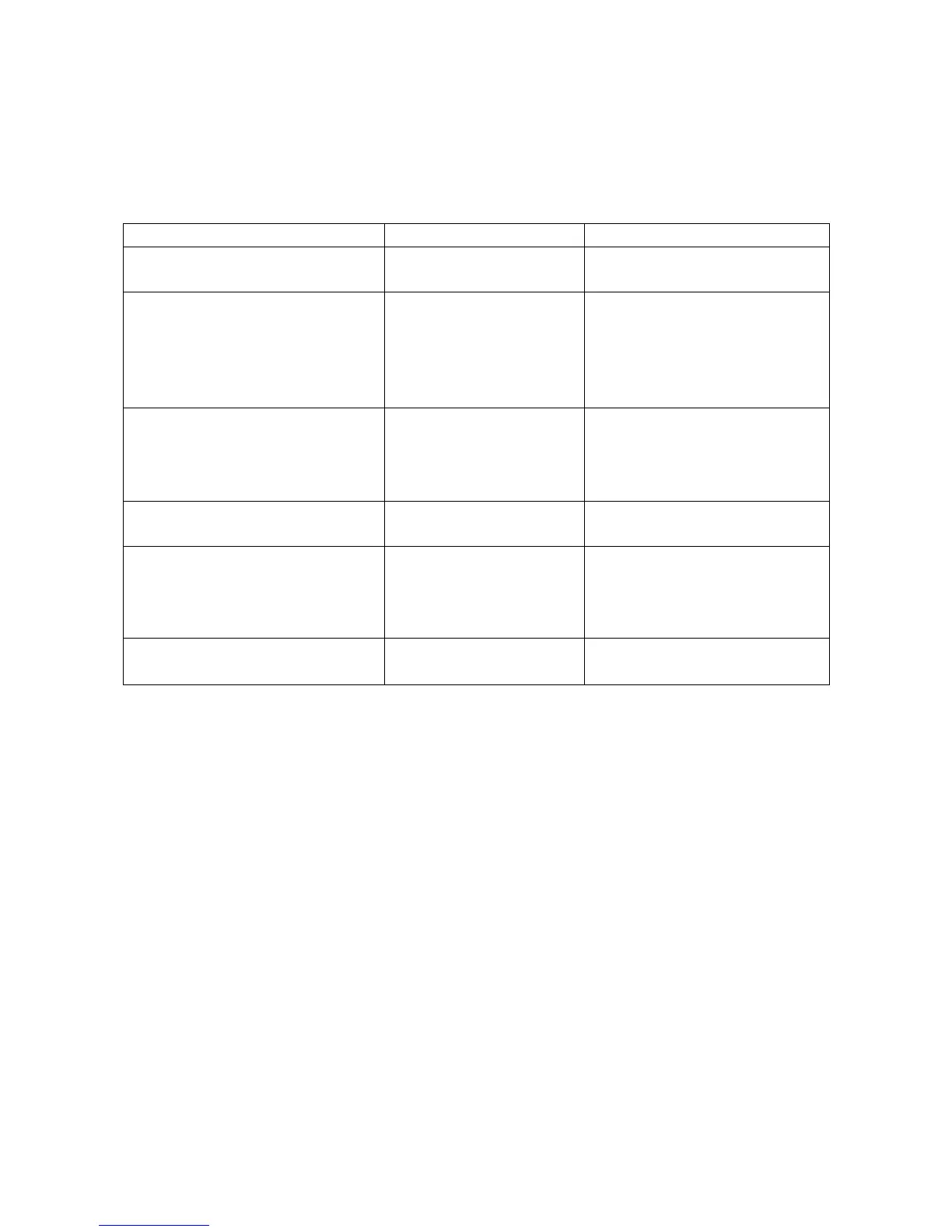

Abnormal Phenomenon Major Cause(s) Actions

Crane cannot operate but can travel

• Work selector switch not

at “CRANE”

• Operate the work selector switch

to “CRANE”

• Traveling speed, boom and hook

block operation speed too slow

• Abnormal noise from pump

• Insufficient hydraulic oil

• Hydraulic oil tank strainer

and element clogged

• Refill with hydraulic oil to the

specified oil level, referring to the

section “Check before operation”

• Clean and replace the filter by

referring to the “Periodical

Checks”.

Hydraulic oil temperature too high

• Insufficient hydraulic oil

• Between cooling fins

clogged

• Refill with hydraulic oil to the

specified oil level, referring to the

section “Check before operation”

• Clean

• Rubber tracks coming off

• Abnormal wear on the sprockets

• Rubber tracks too loose

• See “Check before operation”

and adjust the tension

Outriggers cannot operate

• Outrigger rotary not

rotated to extension

position (outward).

• Work selector switch not

at “OUTRIGGER”

• Secure the rotary at the

extension position

• Operate the work selector switch

to “OUTRIGGER”

Crane and outriggers cannot operate

• Work selector switch at

“DRIVE”

• Operate the work selector switch

to “OUTRIGGER” or “CRANE”

Loading...

Loading...