4-14

[INSTALLATION RUBBER TRACK]

• Have a grease gun available.

• Have a steel pipe available.

1. See “Operation 2.14 Outrigger Setting Operation” to set the

outriggers and raise the rubber track again for about 50mm from

the ground.

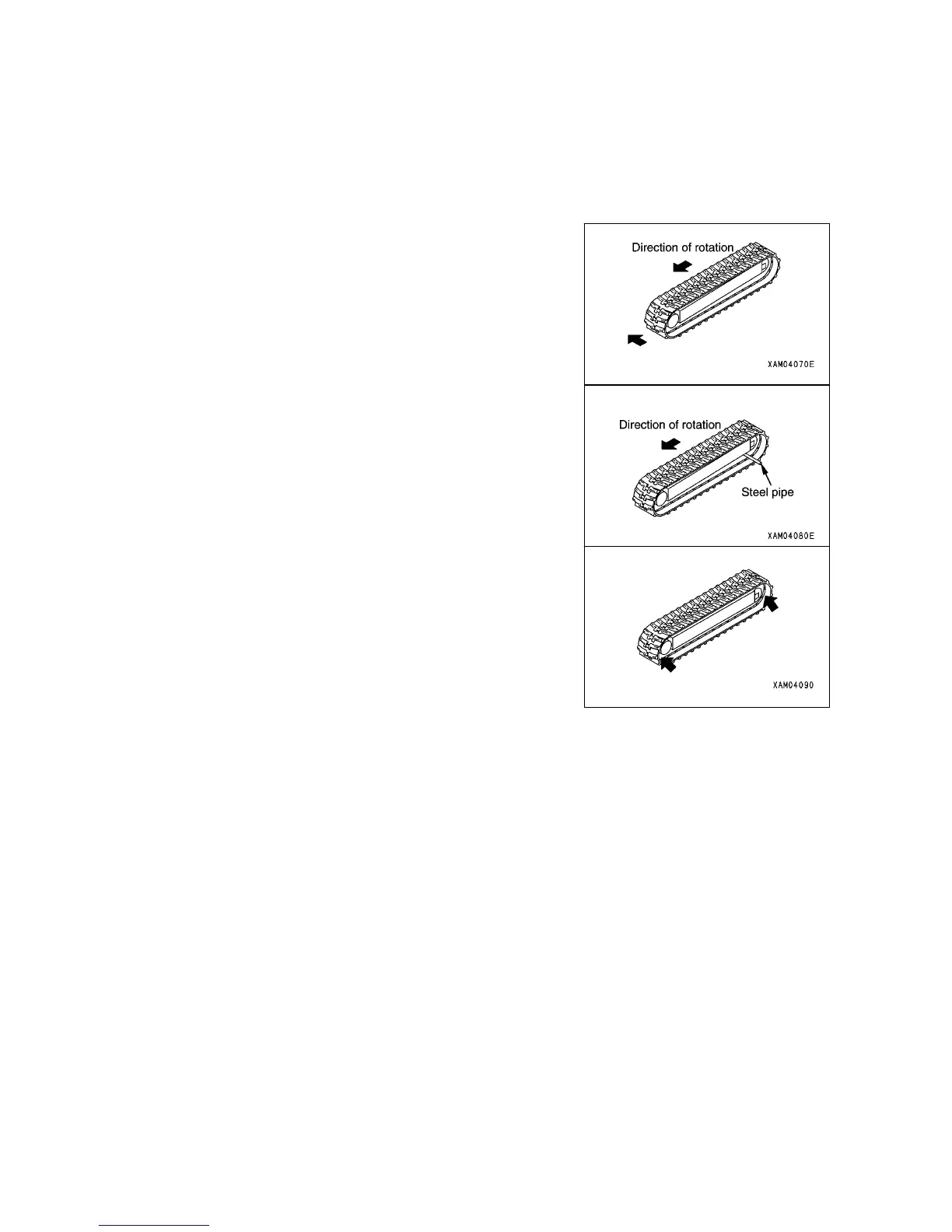

2. With the rubber track engaged with the sprocket, put the crawler

on the idler.

3. With the sprocket rotating backward, push the rubber track in to

stop rotation.

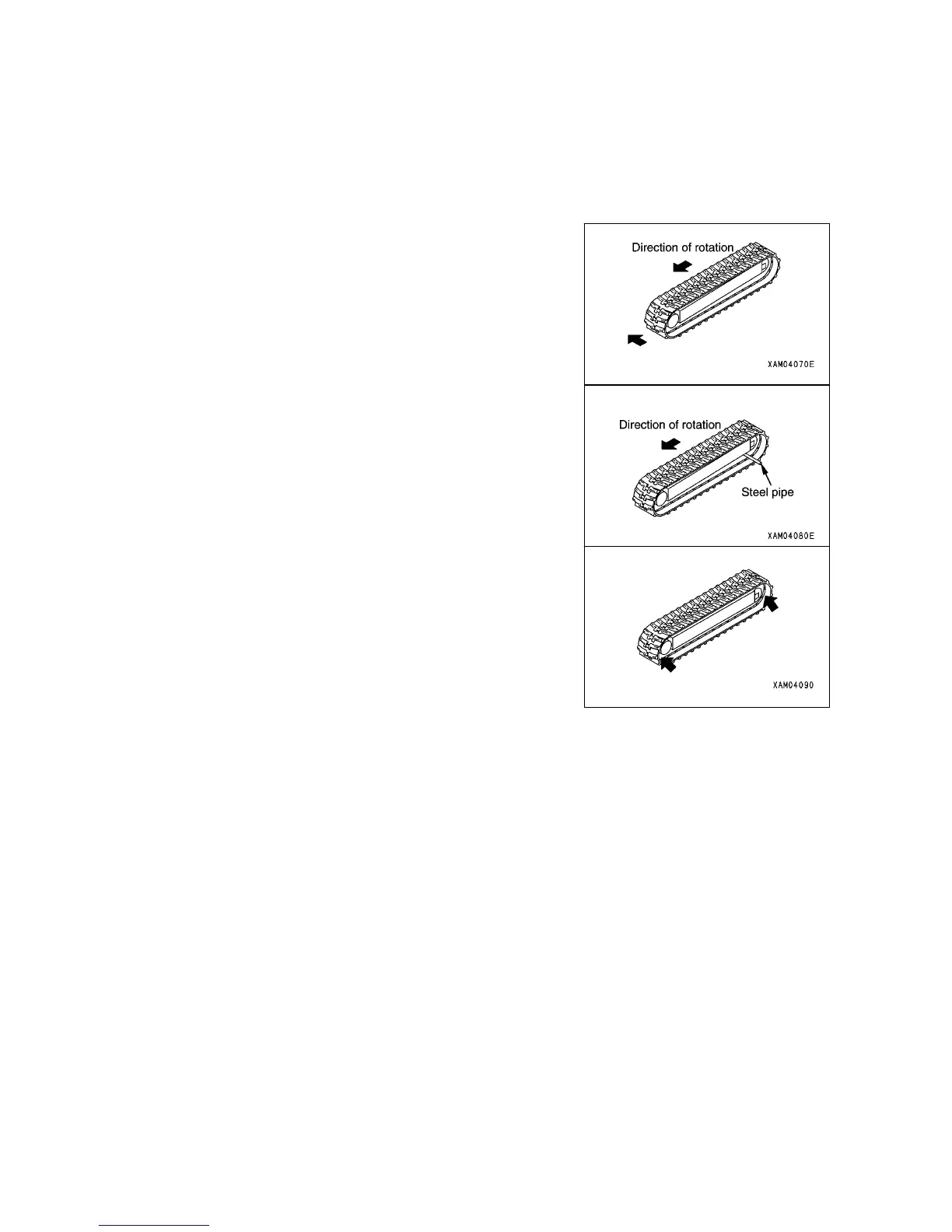

4. Insert the steel pipe between the idler and rubber track again,

and re-rotate the sprocket to put the crawler on the idler properly.

5. Stop rotation, and ensure that the rubber track is on the sprocket

and idler properly.

6. Make a tension adjustment to the rubber track according to

“Operation 2.1.2 Checking Before Operation [9] Checking /

adjustment Rubber Track” in the Operation.

7. Ensure that adequate engagement and tension of the rubber

track, sprocket, and idler are obtained.

8. See “Operation 2.24 Outrigger Stowing Operation” to stow the

outriggers and lower the machine on the ground.

Loading...

Loading...