2-30

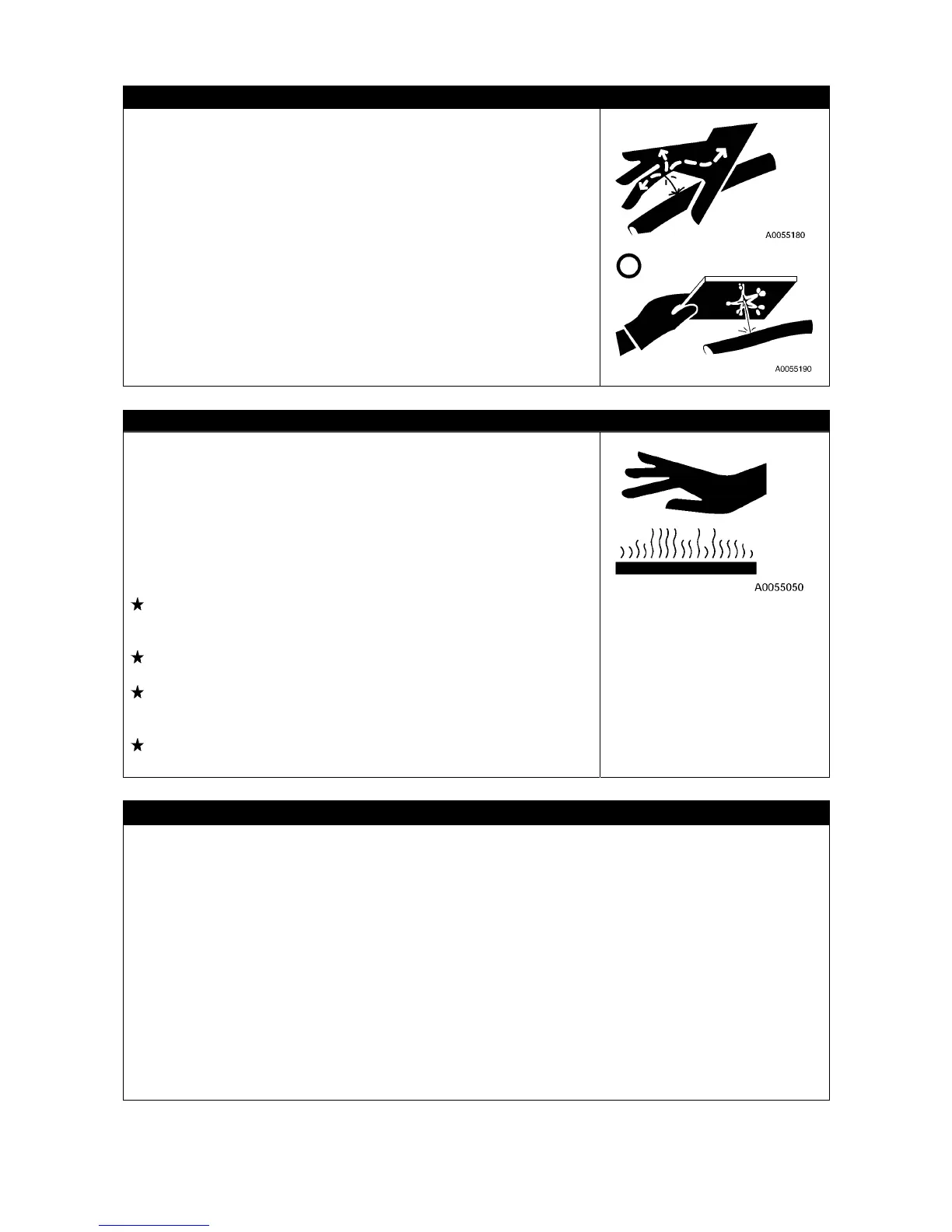

HIGH PRESSURE OIL CAUTIONS

Failure to make sure the pneumatic circuit pressure is relieved before

inspection or replacement of a high pressure piping or hose may

result in bodily accidents.

Always observe the followings.

• Do not start any inspection or replacement before the pressure

dissipates.

• Put on protective glasses and leather gloves.

• When a piping or hose leak exists, the piping/horse itself or vicinity

or the ground is wet. If such is seen, a piping crack, hose crack or

inflation is considerable, so always ask us or our sales service

agency for a repair.

• High pressure oil leaking through a small hole may puncture the

skin or destroy eyesight upon contacting with skin or eye.

If the high pressure oil gave serious injury to skin or eye, wash away

with flowing water and see the doctor as soon as possible.

CAUTIONS WHEN TEMPERATURE IS HIGH

Parts such as the engine, all oils, exhaust system manifold and

muffler are at high temperature during short time after stopping the

engine.

Attempt to remove the cap or execute a maintenance such as oil

draining, water draining or filter replacement may result in suffering

burns.

Wait until the temperature lowers, then execute the

inspection/maintenance following the procedure written in this

manual.

Operation 2.1.2 Checking Before engine starting: checking cooling

water level, checking oil level in engine oil pan, checking oil level in

hydraulic oil tank.

Maintenance 8.8 250 hours maintenance: Replacement engine

lubrication oil and filter cartridge,

Maintenance 8.9 500 hours maintenance: Replacement engine

lubrication oil and filter cartridge, replacement hydraulic oil return

filter

Maintenance 8.10 1000 hours maintenance: Cleaning inside

cooling system, replacement oil inside hydraulic oil tank

CHECKS AFTER INSPECTION/MAINTENANCE

Failure to execute an inspection/maintenance item or failure to check the function and operation of the

maintained part may cause an unexpected fault which may result in bodily accidents.

Always observe the followings.

• Checks with engine stopped

• Check for unexecuted inspection/maintenance.

• Check that inspection/maintenance was done without errors.

• Check for any dropped tool or part. Ones caught by the interior or lever related link mechanism poses

extra danger.

• Check for any fuel leak, water leak, oil leak, bolt loose and similar issues.

• Check with engine running

Be fully careful with safety when checking with the engine running while referring to "Work by at least

two persons during maintenance with engine running" section.

• Check that the inspected/maintained part operates normally.

• Check that issues such as an oil leak do not occur when load is applied to the oil pressure by

increasing the engine rotation.

Loading...

Loading...