72

Magtrol Model DSP7000 Dynamometer ControllerChapter 7 – Computer Controlled Operation

OPERATION

EXAMPLE

If a motor is running at 1725 rpm clockwise, with the dynamometer loading the motor to

22.6 oz.in., the DSP7000 will return:

S 1725T22.60R

By manipulating the string, the speed-torque and shaft direction (if required) can be extracted.

Then separate numerical variables can be assigned to them for data processing.

7.2.2 ouTpuT Binary CoMManD (oB)

A list of paramaters can be created using the COB (Configure Output Binary) Table. The list can be

retrieved at a rate of 488 samples per second. Up to 35 paramaters can be added to the list making

it possible to read 488 × 35 = 17080 parameters per second all synchronized in time.

1. The user used the COB table to configure the DSP7000 to package the required data.

Minimum command is the return of the timers (COB,0,1).

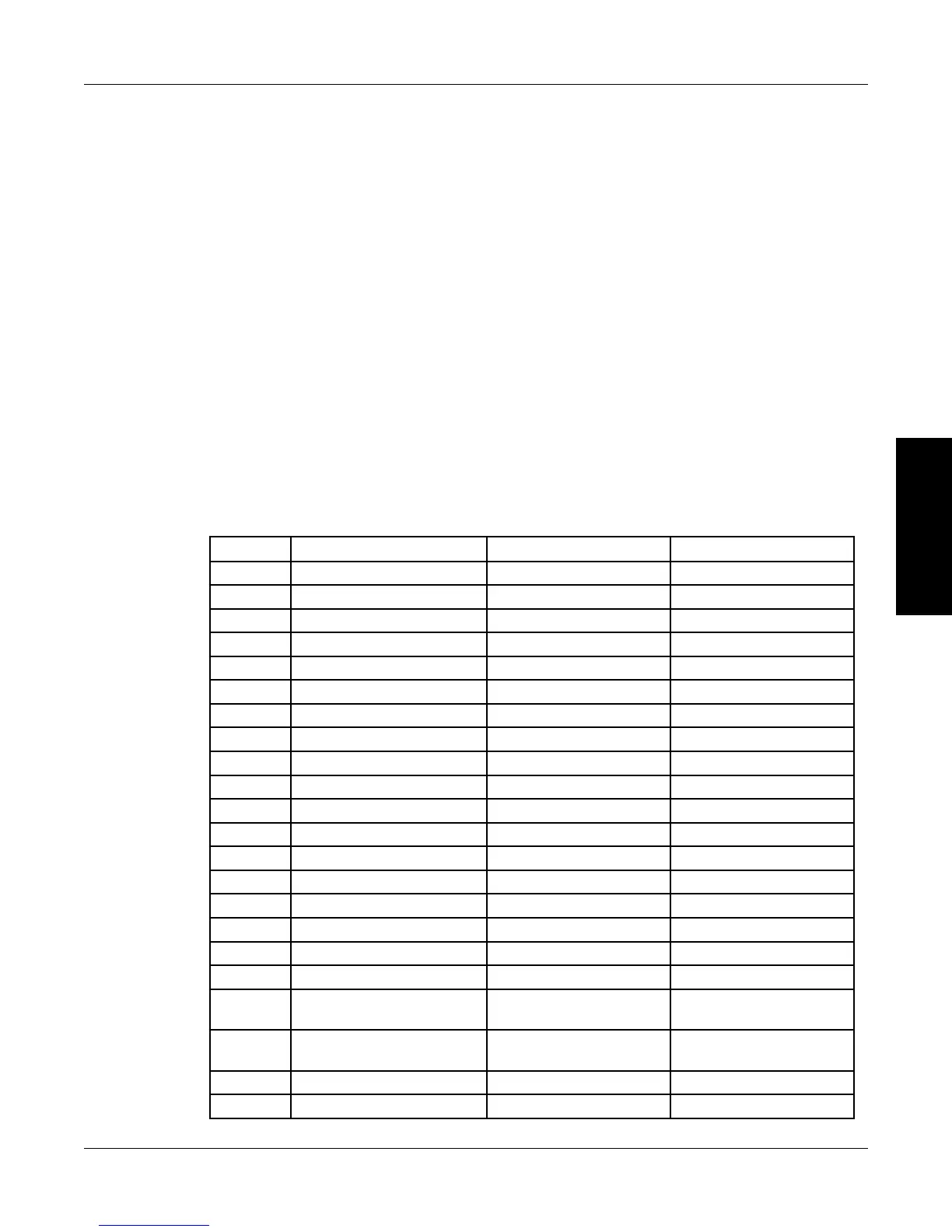

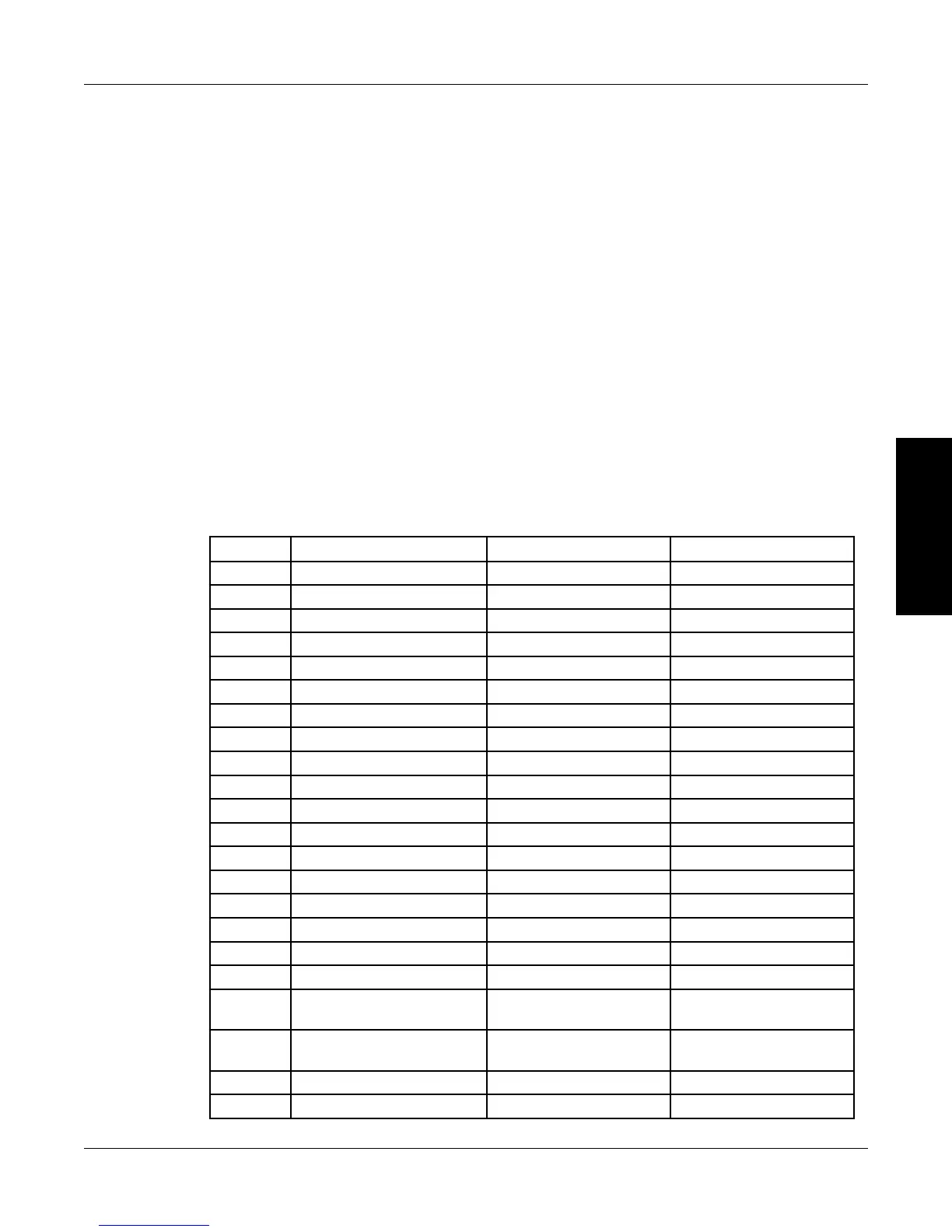

Number Data Description Data Type

0. TimeH Time Stamp HIGH Integer

1. TimeL Time Stamp LOW Integer

2. CNL1 Speed Channel 1 speed Float

3. CNL1 Torque Channel 1 torque Float

4. CNL1 Speed SET POINT Channel 1 set speed Float

5. CNL1 Torque SET POINT Channel 1 set torque Float

6. CNL2 Speed Channel 2 speed Float

7. CNL2 Torque Channel 2 torque Float

8. CNL2 Speed SET POINT Channel 2 set speed Float

9. CNL2 Torque SET POINT Channel 2 set torque Float

10. AI11 I/O card 1 analog input 1 Float

11. AI12 I/O card 1 analog input 2 Float

12. AI21 I/O card 2 analog input 1 Float

13. AI22 I/O card 2 analog input 2 Float

14. Not Dened Float

15. Not Dened Float

16. Not Dened Float

17. Not Dened Float

18. Status 1 Mix channel 1 of DIs and

alarms … TBD

Integer

19. Status 2 Mix channel 1 of DIs and

alarms … TBD

Integer

20. Filter_out1 Float

21. Filter_out2 Float

Loading...

Loading...