HYDRAULIC SYSTEM 16000 SERVICE/MAINTENANCE MANUAL

2-32

Published 05-09-17, Control # 014-28

If you think that a low pressure accessory system is not

operating properly, proceed as follows:

1. Install an accurate 0 to 1,000 psi (0 to 69 bar) hydraulic

pressure gauge between end of supply line and

corresponding port of actuator (brake port, for example).

Fittings are 06 ORS.

2. Release brake by slowly moving control handle in either

direction to operate corresponding function — pressure

should be 400 to 500 psi (28 to 35 bar).

3. Apply brake by moving control handle to off — pressure

should be zero.

4. If pressure is above 500 psi (35 bar), proceed as follows:

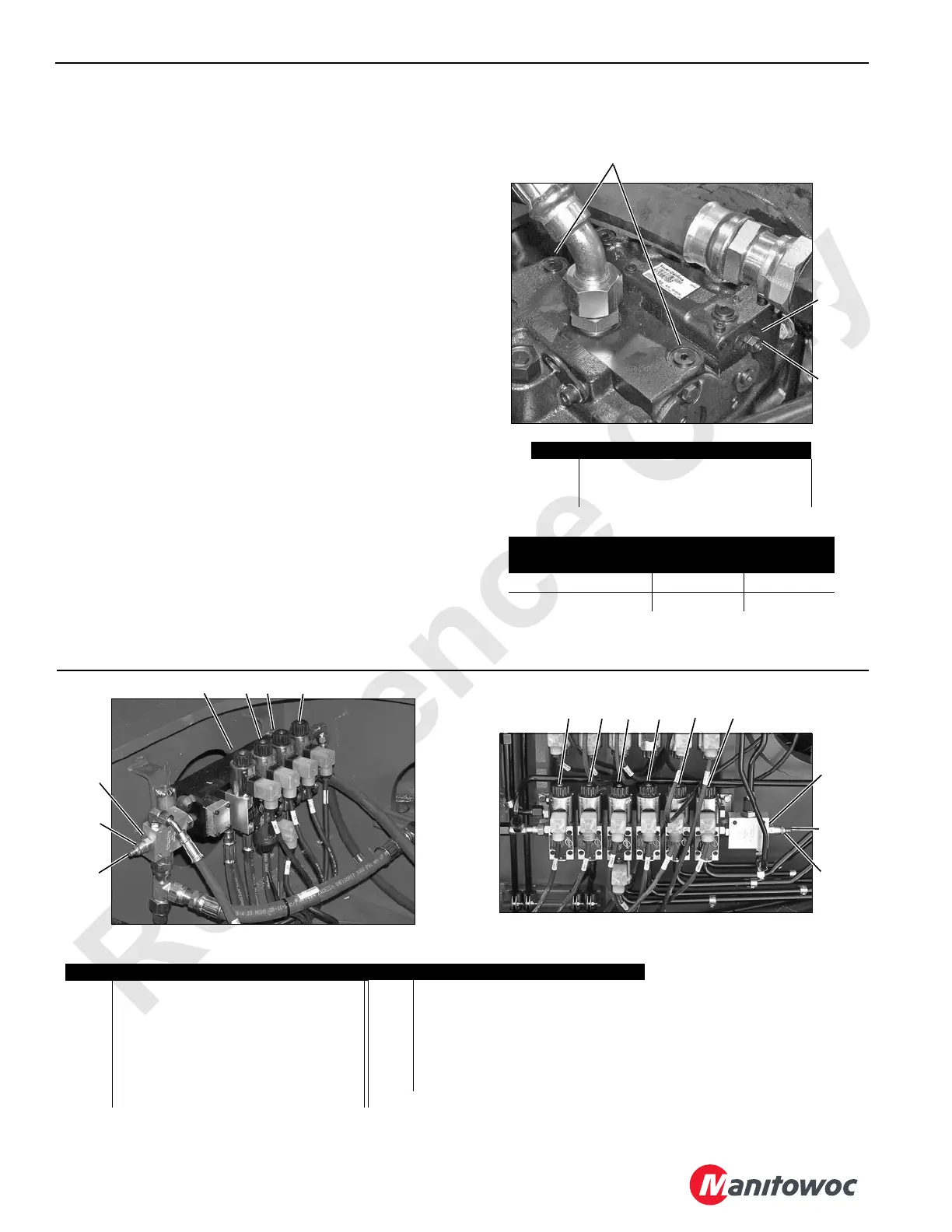

a. Loosen lock nut (2).

b. Adjust adjusting screw (3).

- Turn IN to INCREASE pressure

- Turn OUT to DECREASE pressure

c. Start and run engine at high idle.

d. Fully RETRACT (stall) a rotating bed jack with

switch on setup remote control only long enough to

get a gauge reading.

e. Repeat steps until gauge reads no higher than 500

psi (35 bar).

f. Hold adjusting screw in position and securely

tighten locknut.

5. Stop engine, remove gauge, and reconnect hydraulic

lines.

1

2

Item Description

1 Servo Gauge Ports (SAE 06)

2 Lock Nut

3 Adjusting Screw

Wrench Size

Pump Series

Lock Nut

Hex Size

Internal

Hex Size

Early Series Units 17 mm 5 mm

Current Series Units 10 mm 3 mm

FIGURE 2-31

P1535a

Typical Pump Installation

3

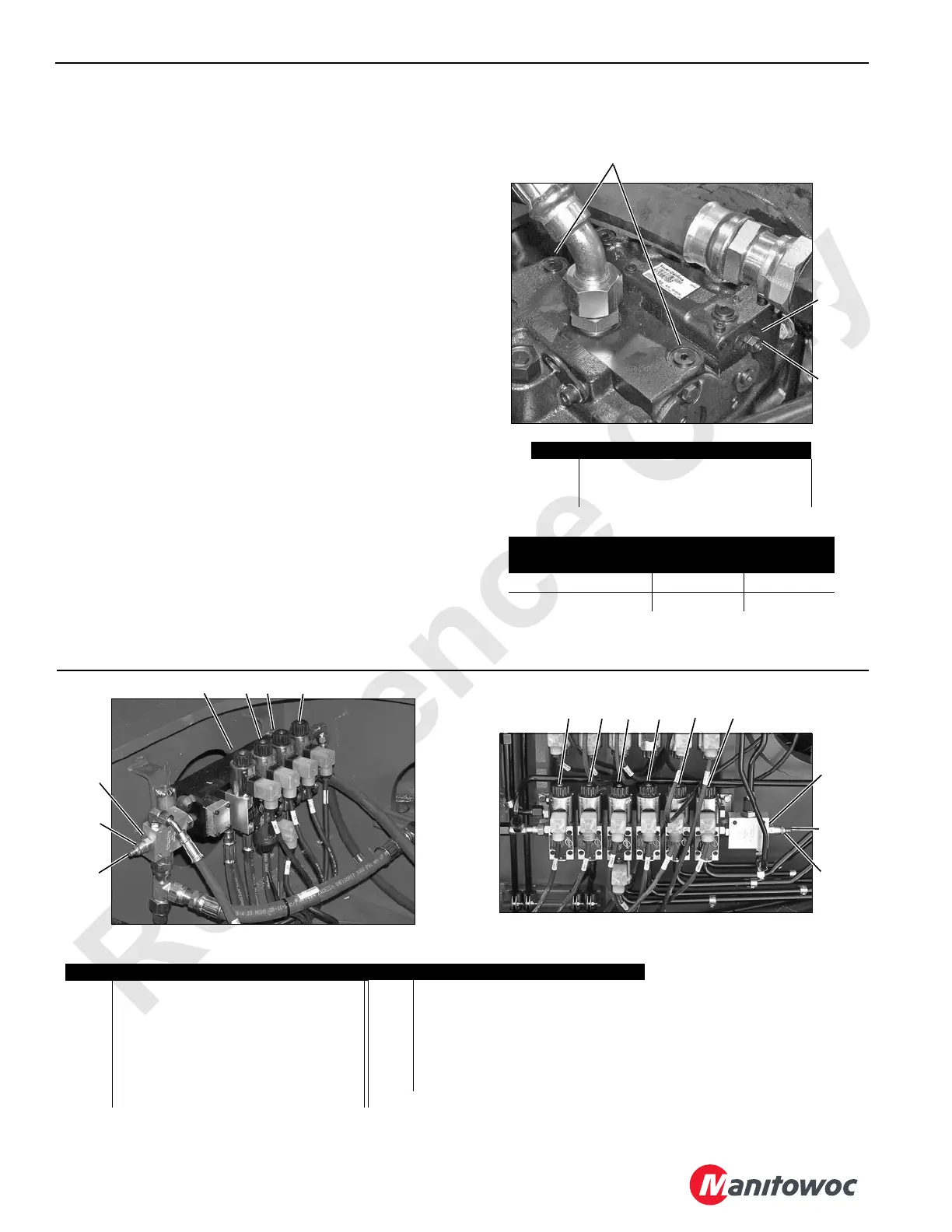

4

P2300

1

5 6 7

3

2

Inside Adapter Frame

FIGURE 2-32

P2308

10

9

12

11

138

1

3

2

Left Side of Rotating Bed

Item Description Item Description

1 Pressure Reducing Valve 8 Drum 2 to Drum 1 Diverting Solenoid

2 Lock Nut – 0.562 inch Hex 9 Drum 1 to Drum 2 Diverting Solenoid

3 Adjusting Screw – 0.188 inch Internal Hex 10 Drum 4 Pawl Solenoid

4 Swing Brake Solenoid Valve 11 R Travel to Drum 4 Diverting Solenoid

5 Swing Lock Solenoid Valve (past

production)

12 L Travel to Drum 3 Diverting Solenoid

6 Travel Brake Solenoid Valve 13 Drum 4 to Drum 5 Diverting Solenoid

7 Travel 2-Speed Solenoid Valve

Loading...

Loading...