Grove Published 3-22-2021, Control # 702-02 4-39

GRT8120 OPERATOR MANUAL OPERATING PROCEDURES

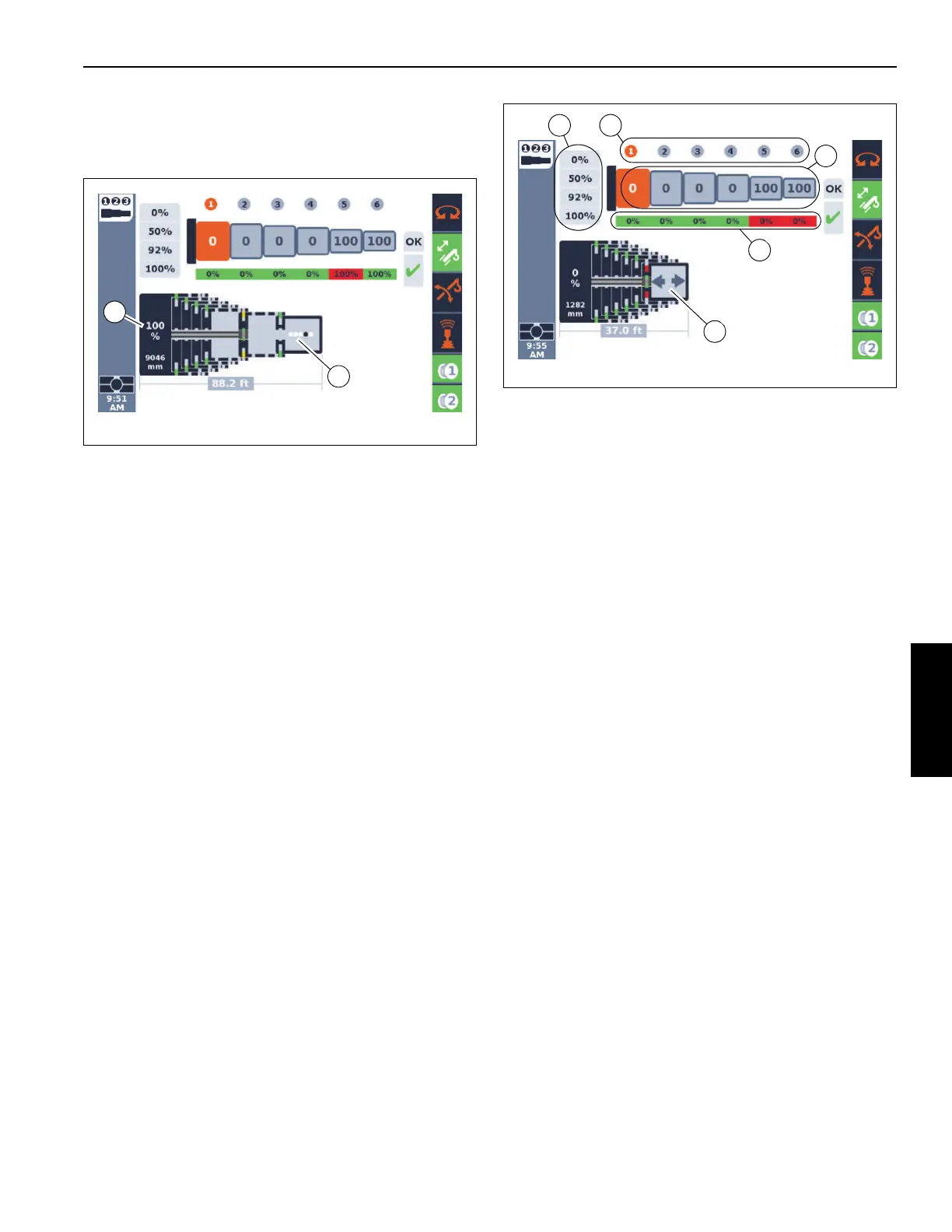

The end of the graphical representation of the rod at the T5

boom section which is at the 100% pinning location. The

slightly larger rectangular entity at the right end of the

telescoping cylinder rod represents the pinning mechanism.

The example in Figure 4-32 shows the value of 9046 mm for

the extension of the telescoping cylinder within the boom.

This is the value from the precision length sensor. The

example also shows a value of 88.2 ft as the overall boom

length. The example shows the T6 boom section had been

previously extended and locked at its 100% pinning location

and the T5 boom section is being pinned at the 100% pinning

location. The remaining boom sections are locked at their

0% pinning location.

As mentioned earlier, there are times when the crane control

system is performing automated motions. The example in

Figure 4-32 shows some moving dots (2) at the end of the

schematic graphic. These dots, as well as the one dark dot

cycling back and forth to the left and right, indicate that

automated motions are occurring.

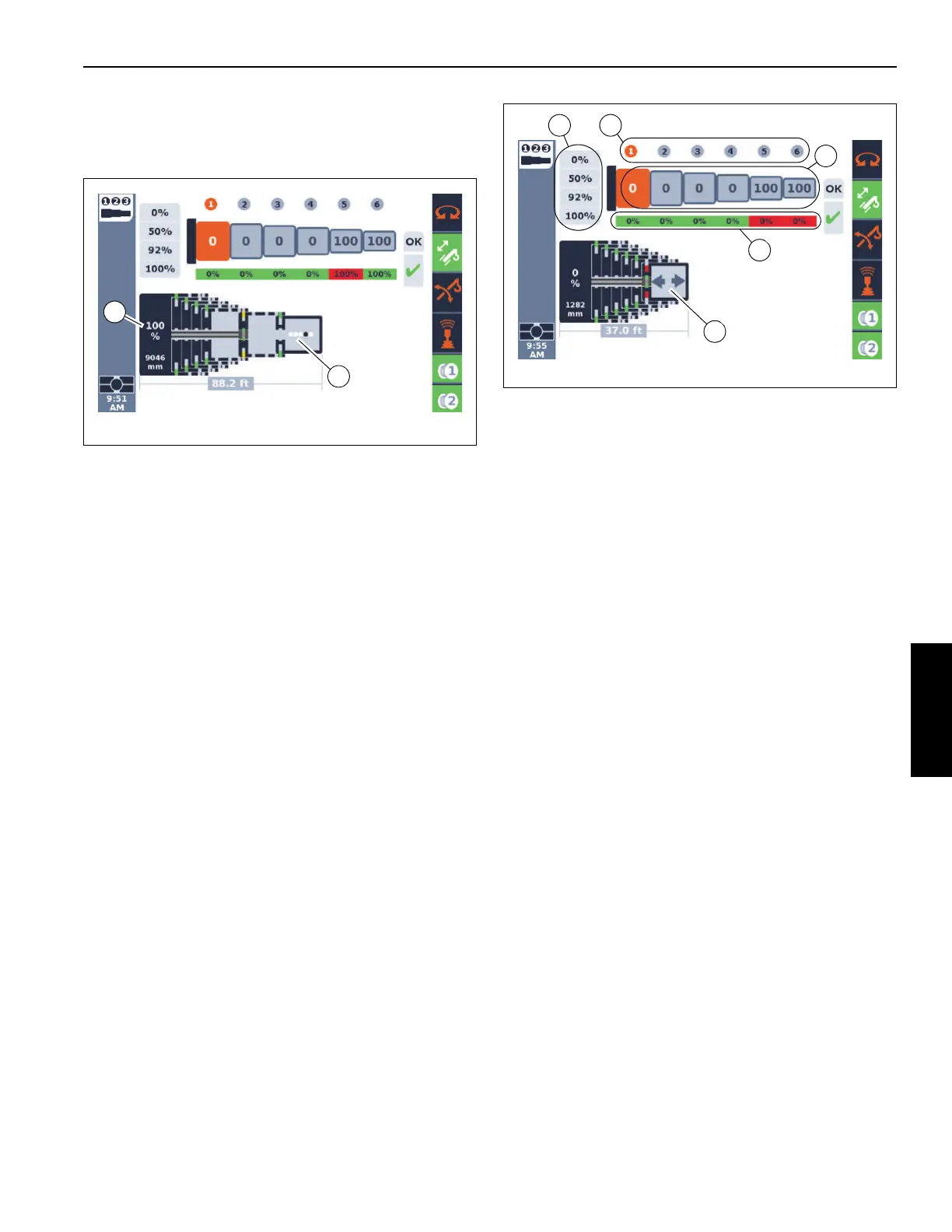

Figure 4-33 shows the same screen when the operator is

able to control motions of the boom sections. In this case,

there is a left and/or right pointing arrow (1) (instead of the

dots shown in Figure 4-32). As is consistent with the

schematic's orientation, the left arrow indicates retracting the

boom, the right arrow indicates extending the boom. The

control device (typically the controller in the standard

controller option) would be moved to the left to retract the

boom, and it would be moved to the right to extend the boom

(while keeping in mind that only one boom section - the

boom section the telescoping cylinder is locked to - would be

moving).

The arrows (1, Figure 4-33), at some point in the telescoping

process, will flash. The flashing is an indication that an

unlocking or locking event will occur if the operator holds the

controller in the direction of that arrow for at least 1 second. If

this event begins, then the screen will change to the dots (as

described for Figure 4-32) so that the operator knows that an

automated motion or action is again occurring.

The RCL must be configured and activated in order to have

automated motions or to have operator control of the

telescoping function. If the Enter Rigging Mode screen on

the RCL display is used (accessed with the '?' icon on the

RCL display), then the telescoping action is paused. When

the check-mark is used on the RCL display to re-activate the

RCL, then the telescoping action resumes (whether

automated motion or operator control).

As seen in Figure 4-33, there are sets of numerical values at

the top portion of the screen above the graphical schematic

of the boom.

First, there is a set of values in a top row with values of 1 to 6

in circles (2, Figure 4-33). The 1 to 6 in the circles indicate

the telescoping boom sections (or “tele sections”). The 1 is

for the boom section that is the largest and closest to the

base section. This is referred to as T1. This then proceeds

from T2 to T6 for the 2 to 6 values.

The values under these boom section indication numbers

represent the requested final boom configuration (or “target

tele picture”). Figure 4-33 shows this set of values as

0-0-0-0-100-100 (3). This means that T5and T6 are to be

extended to its 100% pinning location, T2 is to be extended

to the 100% pinning location, and T1, T2, T3, and T4 are to

remain at the 0% pinning locations. It is vital that the operator

understand that this requested final boom configuration is

the first step in operating the pinned boom in the Semi-auto

Mode. Everything the control system performs with the

Semi-auto Mode is dependent on this requested final boom

configuration.

Loading...

Loading...