MAINTENANCE AND LUBRICATION GRT8120 OPERATOR MANUAL

6-24 Published 3-22-2021, Control # 702-02

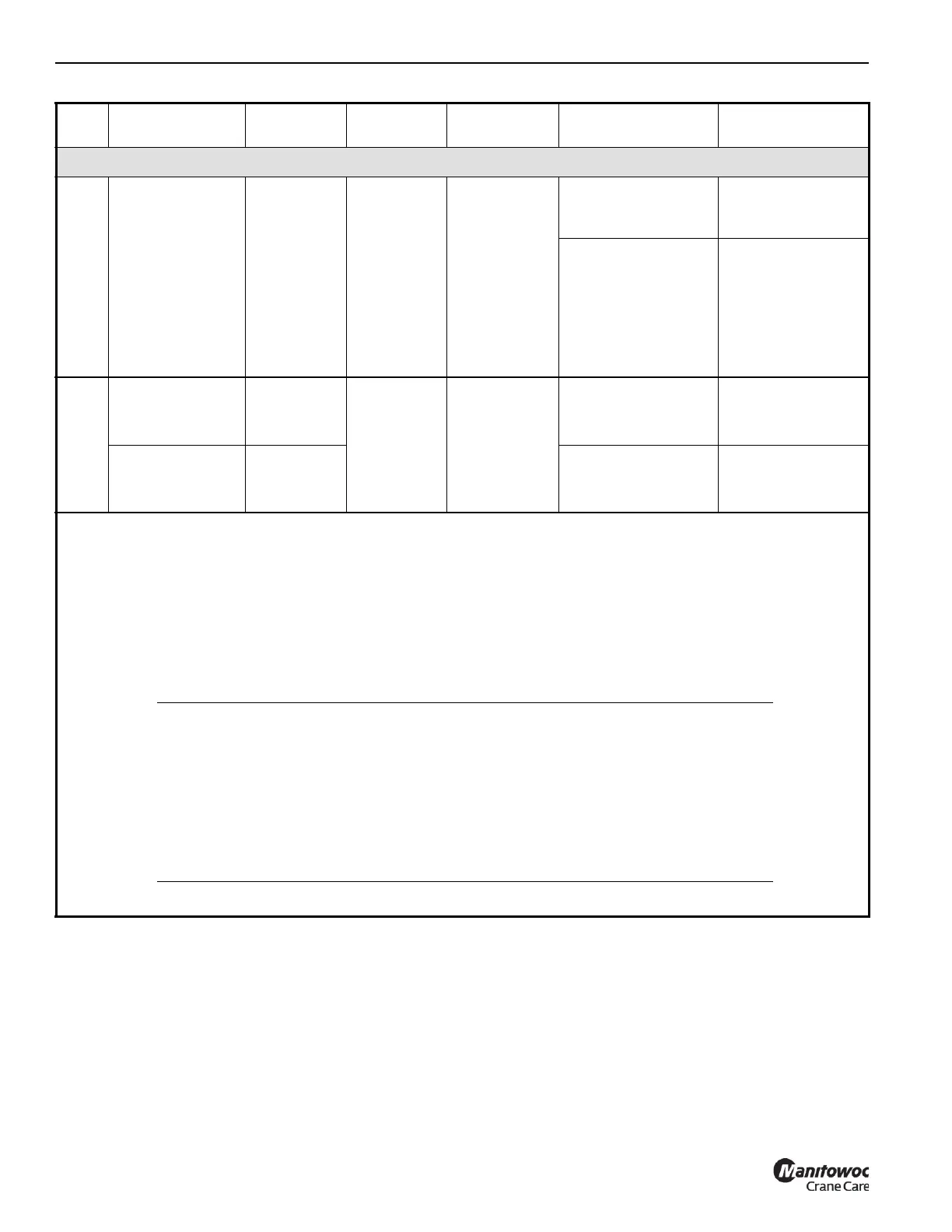

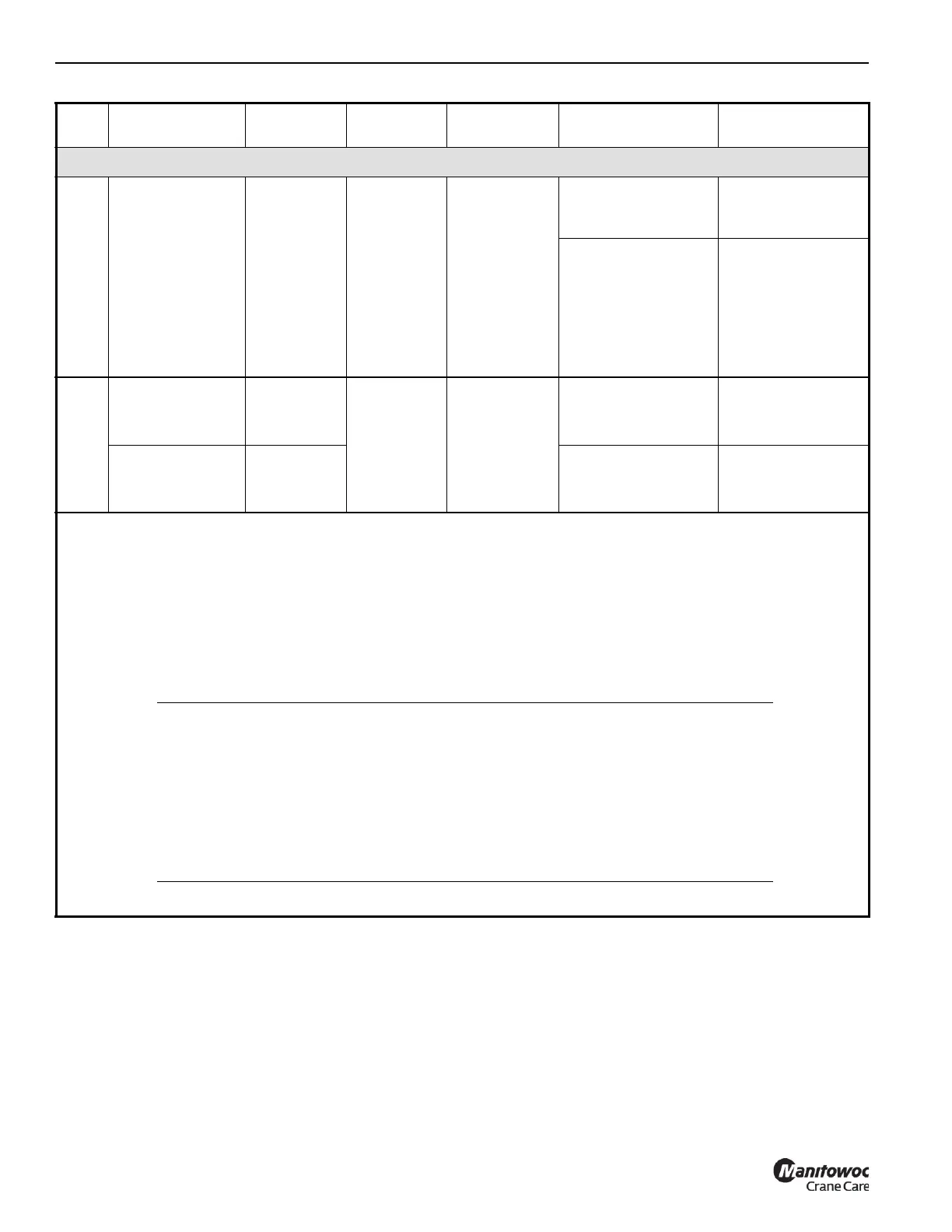

Item

Lube Point

Description

Figure No.

Approved

Lubricant

Approximate

Capacity

Service Interval

Service

Application

Axle Lubrication – Kessler Axles

32 Differentials Figure 6-10 B

37L

(9.8 gal) ea

NOTE 25.

NOTE 26.

NOTE 27.

Every 100 hours, or

1 month, whichever

interval comes first

CHECK and FILL

2 service points

PERFORM after first

100 hours of service

REPEAT every

1000 hours of

service, or 1 year,

thereafter, whichever

interval comes first

DRAIN and FILL

2 service points

CLEAN magnetic

drain plug

INSTALL magnetic

plug in drain port

33

Planetary Hubs &

Wheel Bearings

Figure 6-10

B

2.8 L

(2.9 qt) ea

Wheel End

NOTE 25.

NOTE 26.

NOTE 27.

Every 250 hours, or

1 month, whichever

interval comes first

CHECK and FILL

4 service points

See NOTE 24.

Detail View,

Planetary DRAIN

and FILL ports

Figure 6-10

Every 3000 hours, or

2 years, whichever

interval comes first

DRAIN and FILL

4 service points

See NOTE 24.

NOTE 24: Planetary Hubs and Wheel Bearings must be filled to oil fill level indicated on axle hub. To provide sufficient

lubrication, final fluid level MUST BE LEVEL with the filler plug hole at the Wheel End, with fluid even slightly

dripping from the hole. CLEAN magnetic plug, then INSTALL magnetic plug in drain port.

NOTE 25: Before operating crane in cold weather (arctic) ambient temperatures below -9°C (+15°F), Standard bearing

lubricant must be fully purged and replaced with Cold Weather lubricant meeting Grove U.S. L.L.C.

specifications as shown in Table 6-4: Approved Lubricant Reference Table, page 6-11 in this Operator Manual.

See also your GRT8120 Service Manual for maintenance and lubrication instructions.

NOTE 26: If the makeup amount of fluid is substantially more than 0.23 L (0.5 pt), CHECK for leaks.

NOTE 27: DO NOT USE non semi-synthetic lubricant. Use of non-approved lubricant may damage components.

CAUTION

Possible Equipment Damage!

Use specified semi-synthetic or synthetic lubricants as listed in this section of your GRT8120

Operator Manual. See also your GRT8120 Service Manual for maintenance and lubrication

instructions.

Use of non-approved, non semi-synthetic lubricant may damage components and/or

invalidate published lubricant intervals.

Failure to follow this instruction may cause damage to equipment.

Loading...

Loading...