2. CNC Monitor Screen

2.7 Diagnosis

I - 182

# Parameter Explanation Setting range (unit)

0 INIT. SET

Select the axis for which absolute position initialization is to be

performed:

0: Do not perform initialization.

1: Perform initialization.

(Note) "0" is set when the power is turned on again.

0/1

1 ORIGIN

This parameter is valid when the origin point alignment method is

used. Specify 1 when the machine has been positioned to the origin

point.

(Note) This parameter is invalid for other methods.

0/1

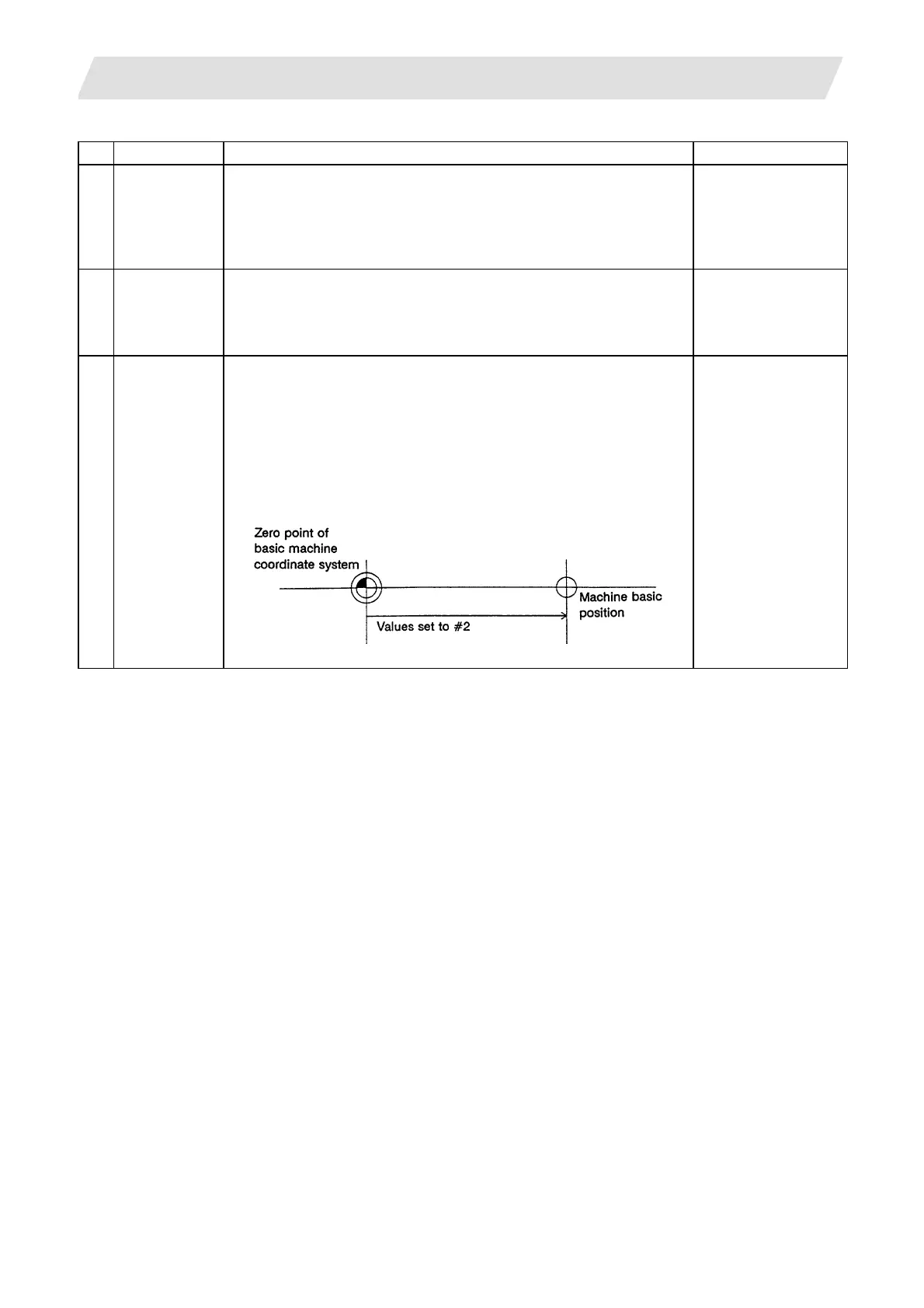

2 ZERO

This parameter is used to determine the basic machine coordinate

system.

Specify the coordinates of the machine basic position seen from the

zero point of basic machine coordinate system or absolute position

basic point.

(Whether the machine basic position or absolute position basic

point is used is determined by data specified for #2059 "zerbas" of

the setup parameter.)

ZERO

±99999.999 (mm)

This section explains only the ABS POSITION SET screen. For details of the actual absolute position

initialization and display contents, see the Setup Manual.

Loading...

Loading...