2. CNC Monitor Screen

2.2 Monitor

I - 19

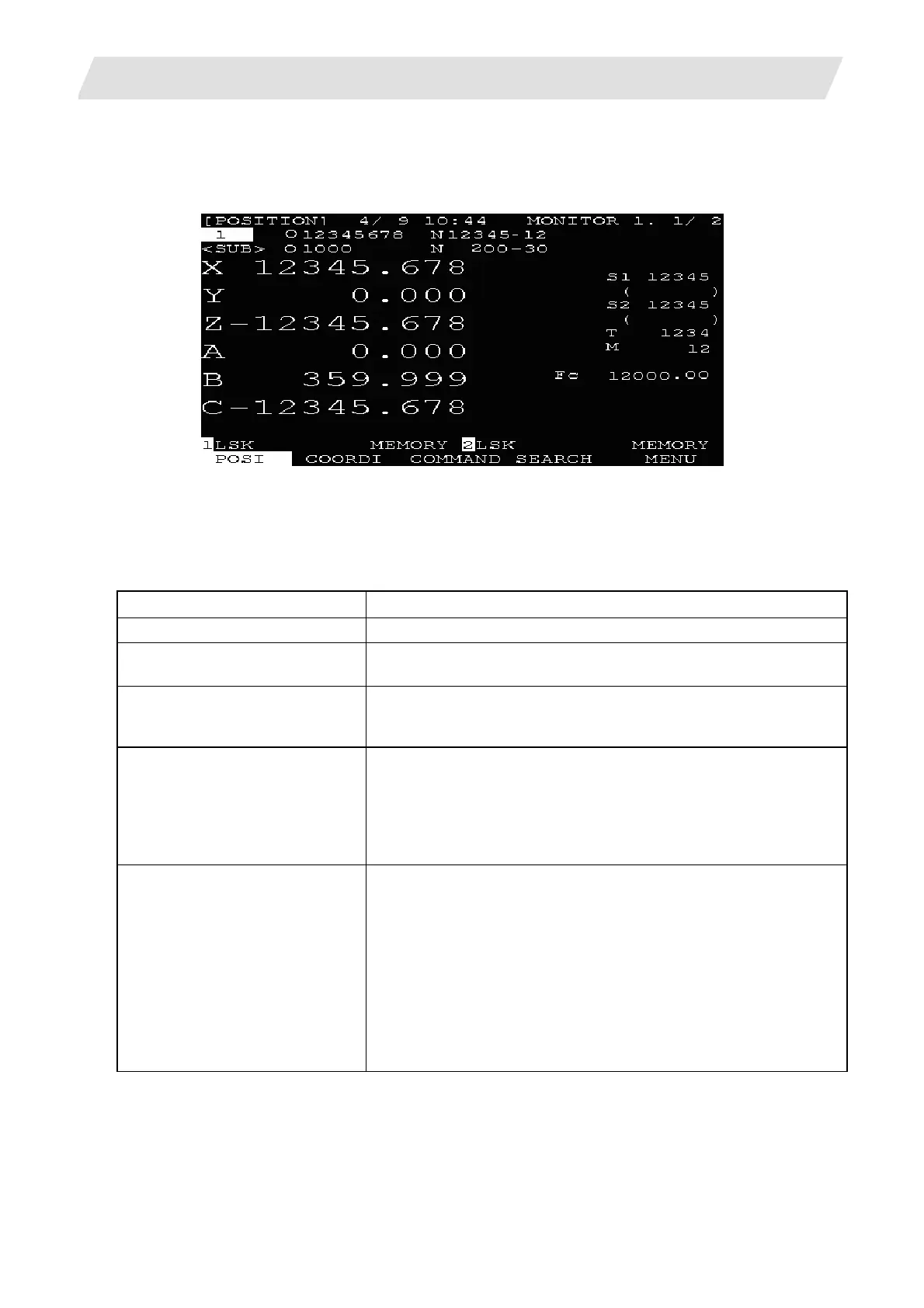

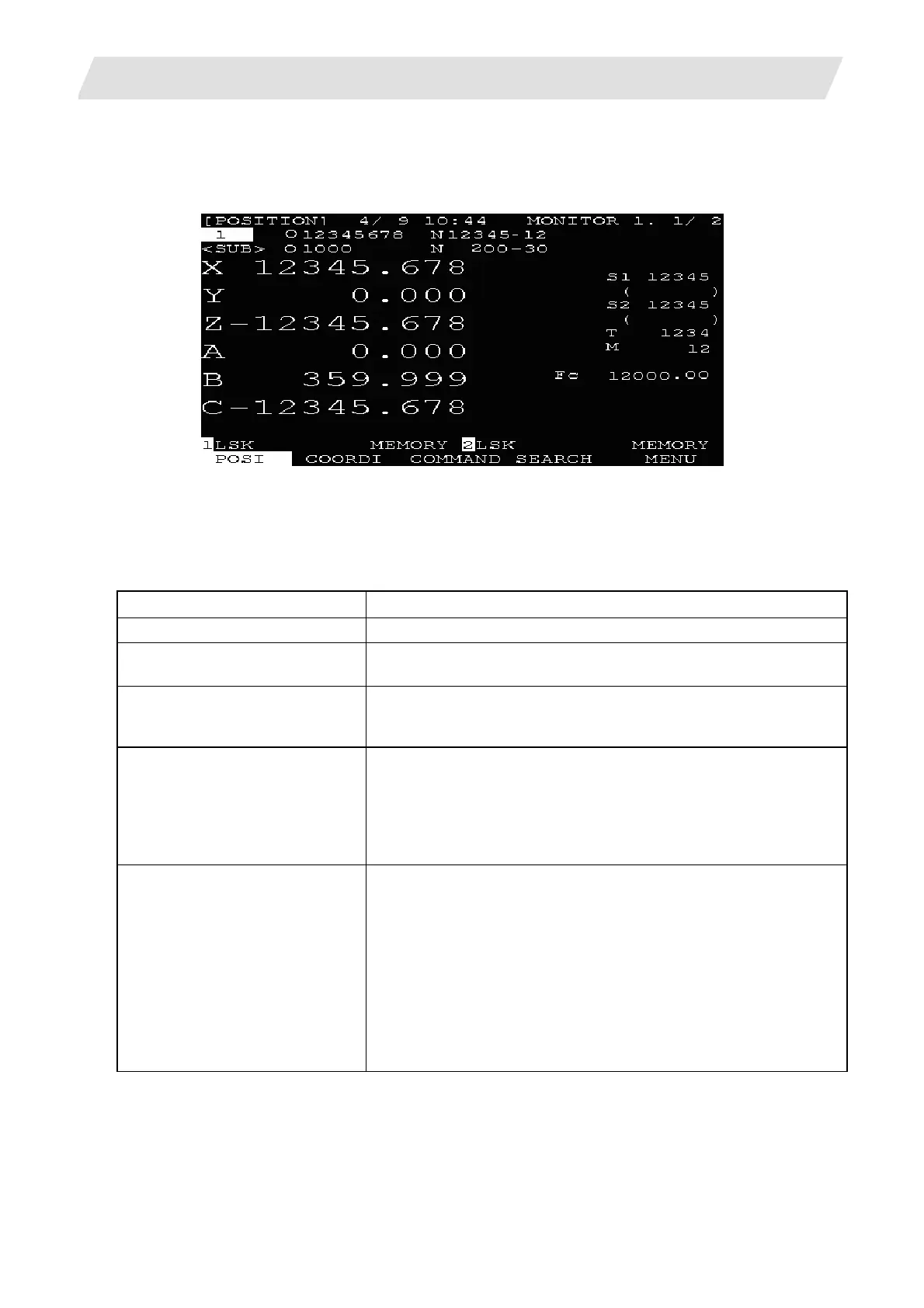

2.2.1 Position

When the menu [POSI] is pressed, the POSITION screen is displayed.

(6-axis specifications)

The following can be performed on the POSITION screen:

(1) Origin set

The current value (POSITION) data of each axis can be set to 0.

(2) Manual numeric command

Miscellaneous function output of M, S, T, etc., can be set through the screen.

Display item

Explanation

4/9 10:44 The date and the time are displayed.

O12345678 N12345-12

The currently executing program number, sequence number, and

block number are displayed.

<SUB> O1000 N200-30

When a subprogram is being executed, the program number,

sequence number, and block number of the subprogram are

displayed.

X-12345.678

Y 0.000

Z-12345.678

A 0.000

B 359.999

C-12345.678

The current position during execution and its abbreviation (if the

position is specific or is placed in specific state) are displayed.

#1~#4 (first to fourth reference point positions)

] [ (servo off state)

> < (axis removed state)

MR (mirror image)

S1 12345 ( )

S2 12345 ( )

T 1234

M 12

Fc 12000.00

The spindle rotation command value is displayed. The actual spindle

speed is shown in ( ).

When multiple spindles are used, the 3rd and following spindles are

displayed on the following pages.

The tool command value is displayed.

The last four digits of the miscellaneous function command value are

displayed.

During interpolation feed, the speed in the current vector direction in

moving is displayed.

During independent axis feed, the speed of the axis with the highest

speed is displayed.

Loading...

Loading...