2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 44

2.3.2.1 Manual Tool Length Measurement I

(1) Outline

This function automatically calculates the amount of tool length compensation, by moving the tool to

the measurement point with the manual feed. There are two types of measurement methods in manual

tool length measurement I: the base point method and the measurement value input method. The

required method is selected by setting parameter “#1102 tlm”.

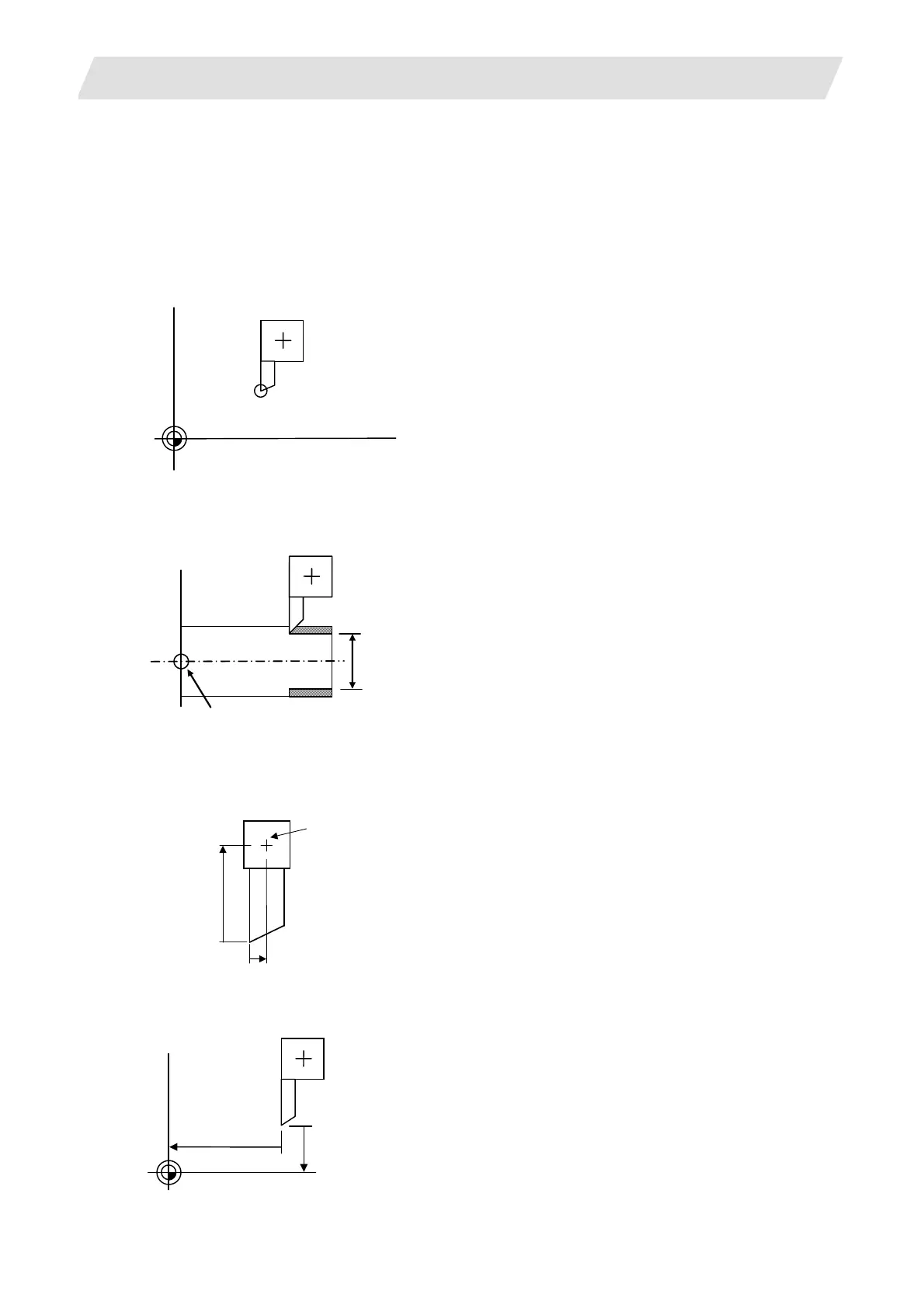

(a) Base point method

Obtain the tool length with the tool nose placed on the measurement point.

Measurement point

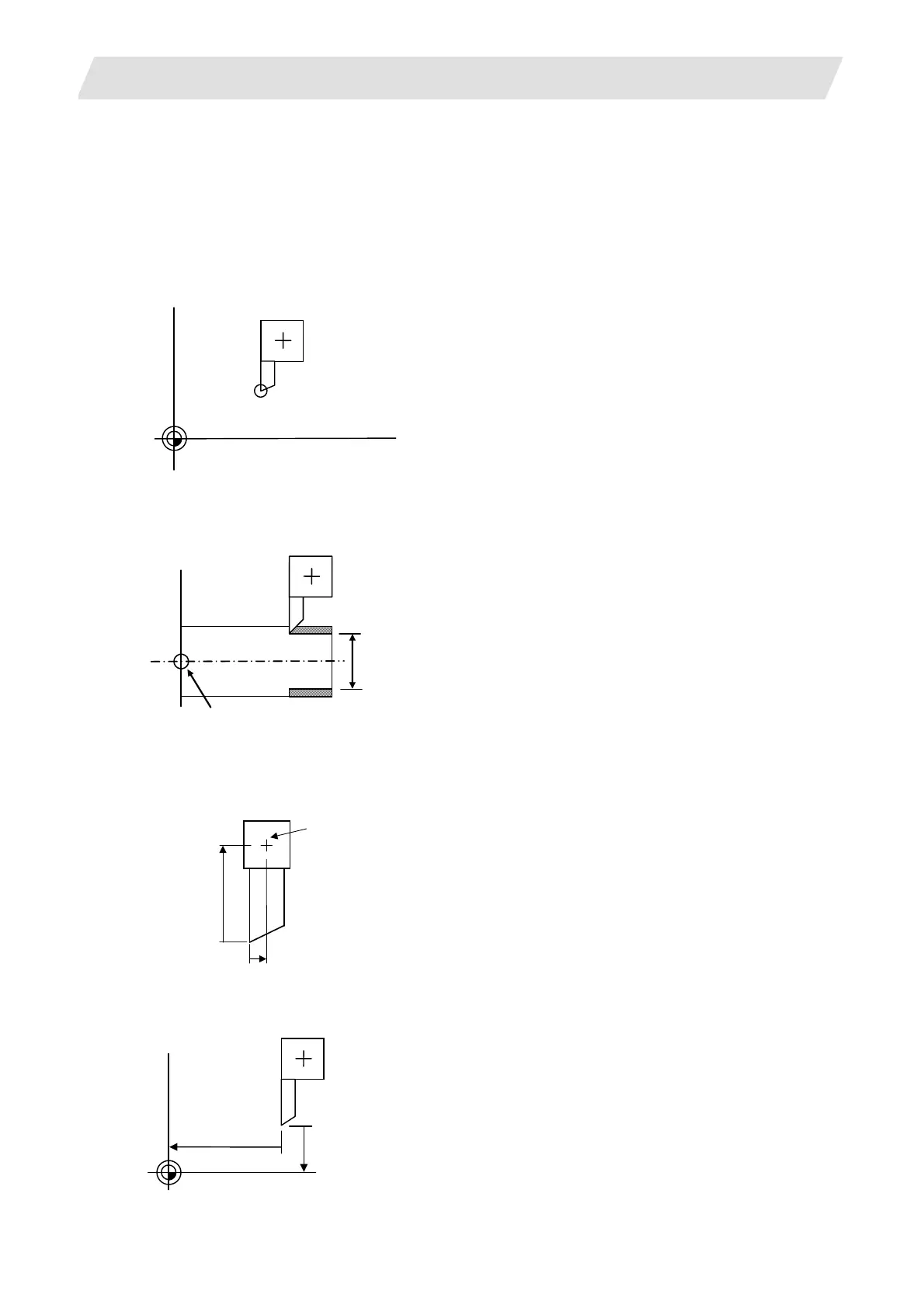

(b) Measurement value input method

Actually cut the workpiece. Measure its dimensions, and obtain the tool length from the measured

values.

Workpiece

Measurement base point

Measurement value

(Note) The tool length from tool length measurement I is as follows, depending on the whether the 1st

reference point coordinate values have been set.

If the 1st reference point coordinate values have been set:

X-axis tool

length

Tool base position

Z-axis tool length

If the 1st reference point coordinate values have not been set:

Z-axis tool length

X-axis tool length

Set the measurement point in parameter “#2015

tlml” beforehand.

The measurement base point is characteristic fo

each machine (the center of the chuck face, etc.).

If the 1st reference point coordinate values have

been set, the tool length is the distance from the

tool's hypothetical nose to the tool base position.

If the 1st reference point coordinate values are set

to 0, the tool length is the distance from the tool's

hypothetical nose to the machine base position.

Loading...

Loading...