2. CNC Monitor Screen

2.7 Diagnosis

I - 204

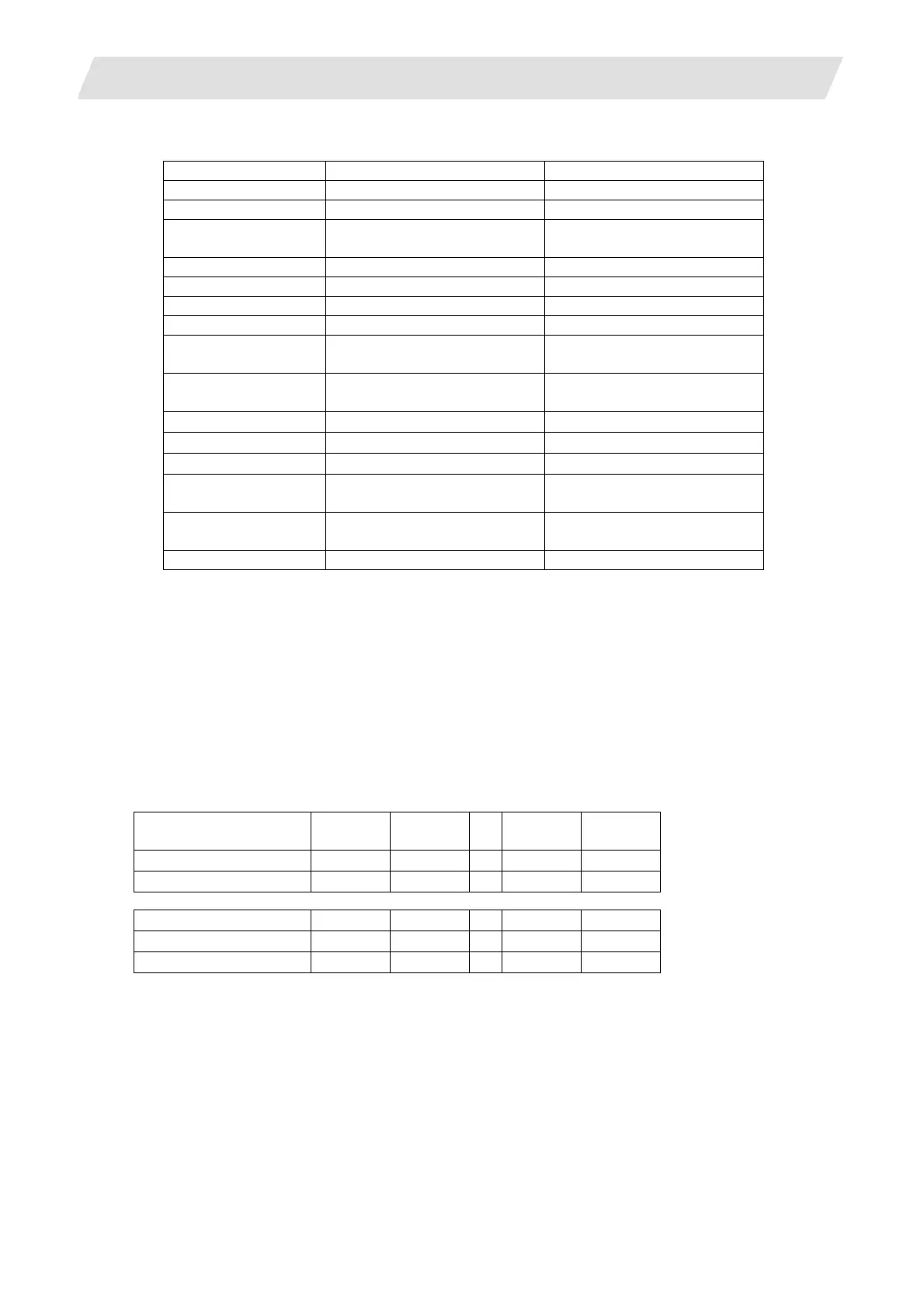

Target No. List (hexadecimal)

Target No. Servo axis, PLC axis Spindle

00 Position FB (Note 1) Position FB (Note 1)

01 Position command (Note 1) Position command (Note 1)

02 Number of motor rotations

(Note 2)

Number of motor rotations

(Note 2)

04 Load current (Note 3) Load current (Note 4)

06 Droop (Note 1) Droop (Note 1)

40 to 45 Control input 1 to 6 Control input 1 to 6

48 to 4D Control output 1 to 6 Control output 1 to 6

7E

-

Spindle position one rotation

data

7F

-

Spindle position FB one

rotation data

80

-

Cycle counter

81 Machine position

-

82

F

Δ

T

-

84

-

Synchronous tapping error

width

85

-

Synchronous tapping error

angle

86 Disturbance load torque Disturbance load torque

(Note 1) Position FB, position command, and droop are output as an interpolation unit.

EX) When "#1003 iunit" is B (1μµm) and output result is 2000:

20000 * 0.5 (interpolation unit) = 1000μm = 1mm

(Note 2) Output unit for the number of motor rotations is 0.01 r/min.

(Note 3) The same value as the load current displayed in the servo monitor screen is sampled for the load

current value of the servo and PLC axes. Output unit is %.

(Note 4) The same value as the load displayed in the spindle monitor screen is sampled for the load current

value of the spindle. Output unit is %.

Droop's sampling result is twice the value of a droop displayed in the servo/spindle monitor screen

of CNC monitor.

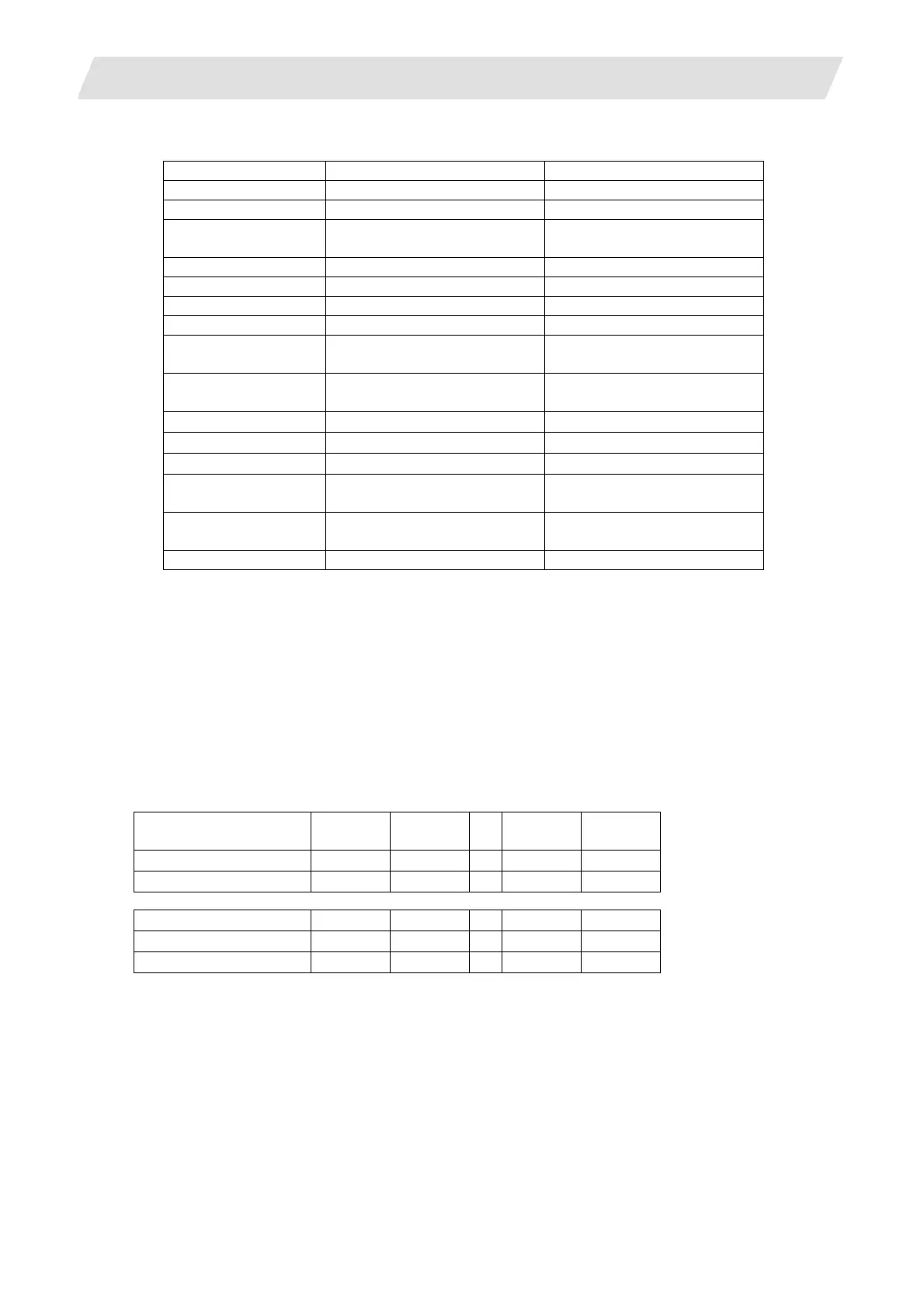

Setting example (of index No.)

Servo axis 1st axis 2nd axis

…

15th

axis

16th

axis

Feedback position

000100 000200

…

000F00 001000

Commanded position

000101 000201

…

000F01 001001

Spindle 1st axis 2nd axis

…

6th axis 7th axis

Feedback position

010000 020000

…

060000 070000

Commanded position

010001 020001

…

060001 070001

Setting examples for each purpose are shown below.

• For synchronized tapping: 3rd servo axis feedback (000300) - 1st spindle feedback (010000)

• For high-accuracy (roundness): 1st servo axis feedback (000100) - 2nd servo axis feedback (000200)

• For spindle synchronization: 1st spindle feedback (010000) - 2nd spindle feedback (020000)

Loading...

Loading...