6-22

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

4.16 Connecting Rod Bearing Thickness - Measure

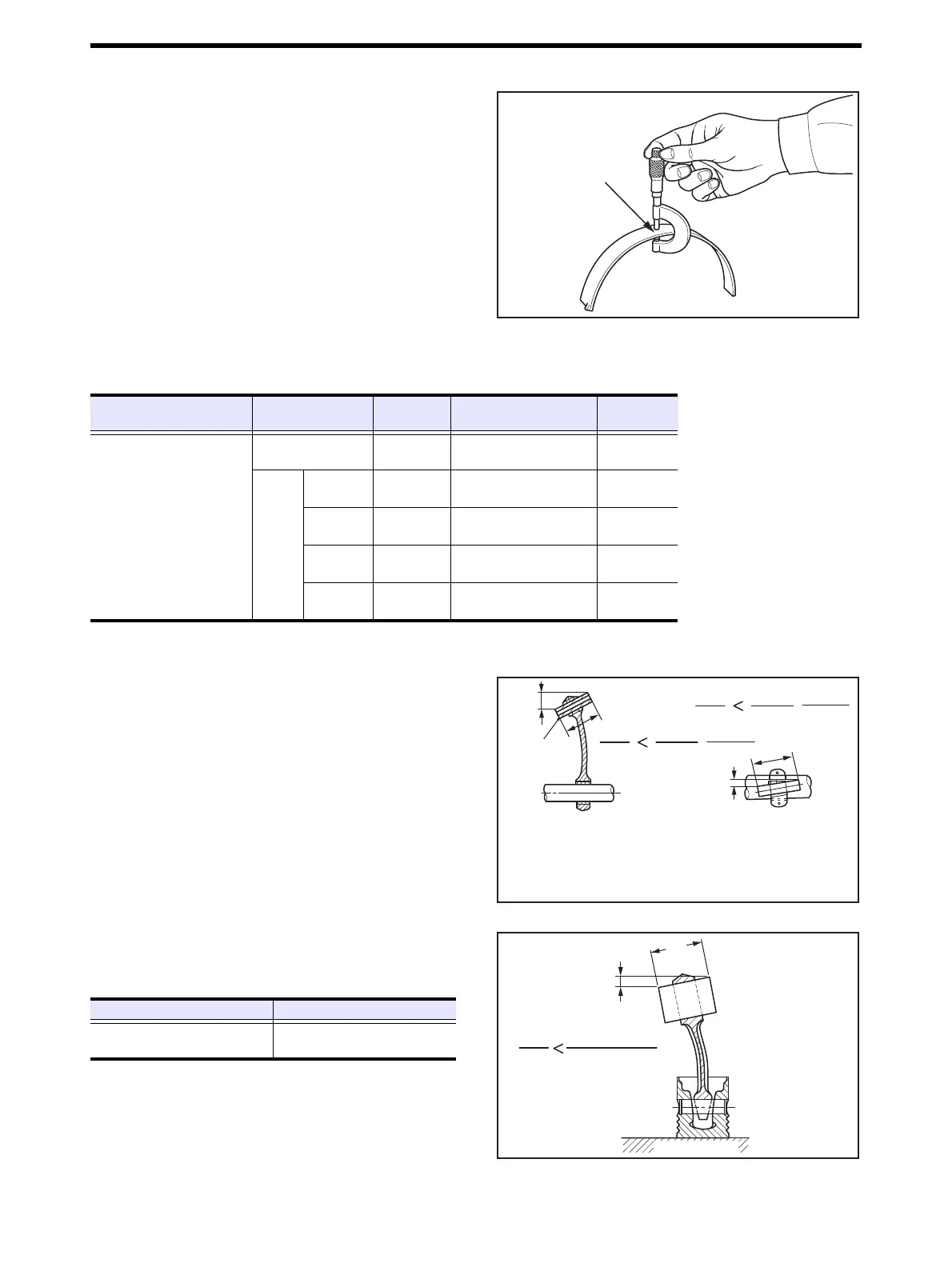

Measure the thickness of connecting rod at its center.

If the value exceeds the limit, replace both upper and lower

connecting rod bearing shells with new ones as a set.When

the crankshaft is re-ground due to wear of crank pin, use the

undersize bearing.

For the crankshaft grinding procedure, refer to "Crankpin

and Crank Journal - Grind" of "INSPECTION AND

REPAIR OF BASIC ENGINE."

Note: Replacement shells for undersized connecting rod

bearing are available in sizes of 0.25, 0.50, 0.75 and

1.00 mm [0.0098, 0.0197, 0.0295 and 0.0394 in.]

Bearing thickness - Measure

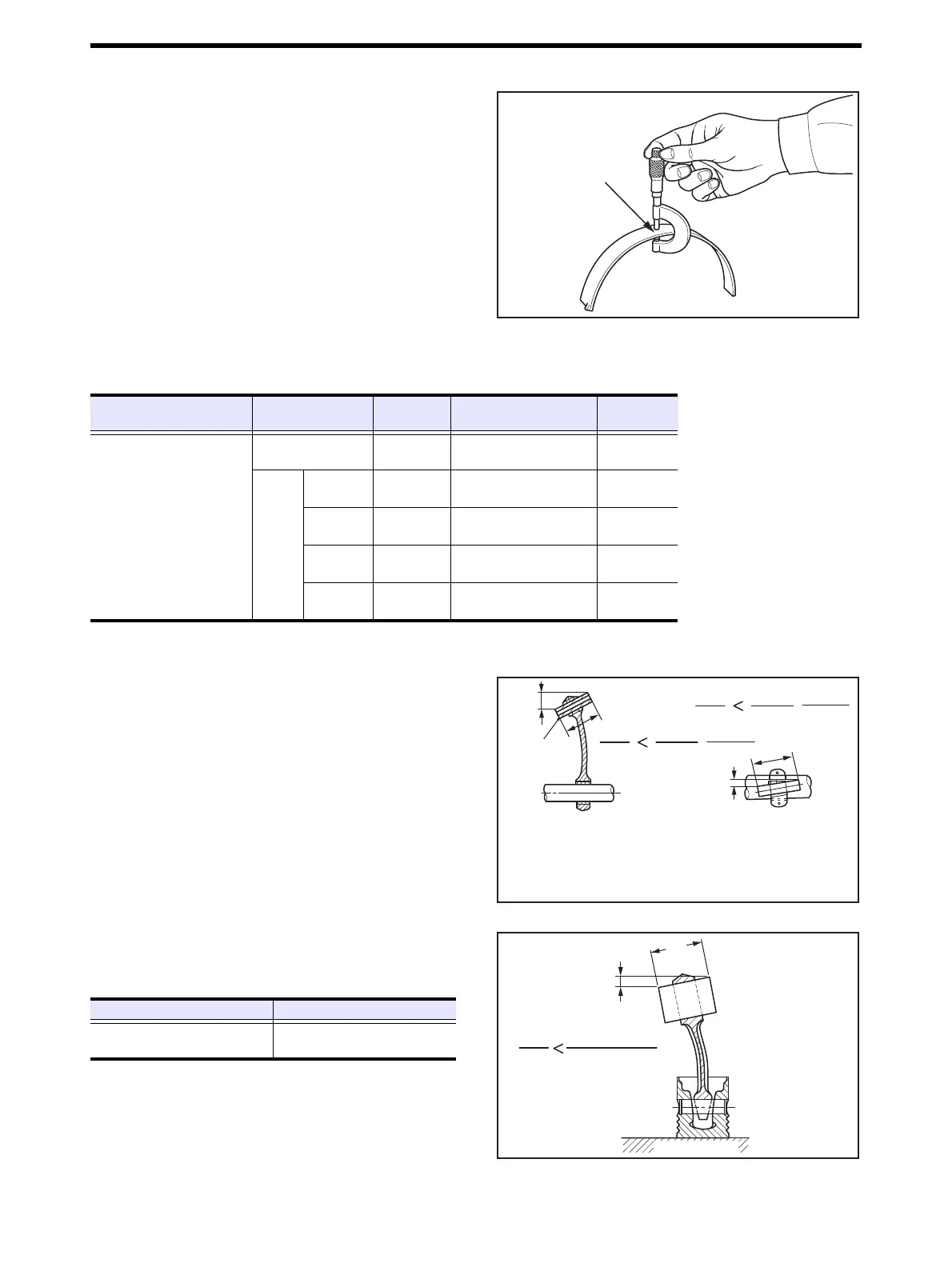

4.17 Connecting Rod Bend and Twist - Inspect

(1) Measure the dimensions of C and L as shown in illus-

tration to check the bend and twist of connecting

rod.Straighten the connecting rod with a press so that

the measurement value meets the standard.

If the value exceeds the limit, replace the connecting

rod with a new one.

Note: Tighten the connecting rod cap to the specified torque

and check the bend and twist.

(2) To inspect the connecting rod with the piston installed,

turn the piston upside down and place it on a surface

plate. Insert a round bar having the same diameter as

the crankpin into the big-end bore, and measure the

height of the bar with dial gauge.

Connecting Rod Bend and Twist - Inspect

Deflection of Connecting Rod - Measure

Measurement

at the center

of bearing

Item Size

Nominal

value

Standard value Limit value

Connecting rod bearing

thickness

Standard

3.000 mm

[0.1181 in.]

2.987 to 3.000 mm

[0.1176 to 0.1181 in.]

2.950 mm

[0.1161 in.]

Under

size

0.25 mm

[0.0098 in.]

3.125 mm

[0.1230 in.]

3.112 to 3.125 mm

[0.1225 to 0.1230 in.]

3.075 mm

[0.1211 in.]

0.50 mm

[0.0197 in.]

3.250 mm

[0.1280 in.]

3.237 to 3.250 mm

[0.1274 to 0.1279 in.]

3.200 mm

[0.1260 in.]

0.75 mm

[0.0295 in.]

3.375 mm

[0.1329 in.]

3.362 to 3.375 mm

[0.1324 to 0.1329 in.]

3.325 mm

[0.1309 in.]

1.00 mm

[0.0394 in.]

3.500 mm

[0.1378 in.]

3.487 to 3.500 mm

[0.1373 to 0.1378 in.]

3.450 mm

[0.1358 in.]

Item Standard value

Connecting rod bend and twist

(C/L, C/D)

0.05/100 mm

[0.0020/3.94 in.] or less

343 ± 17.7 N·m

{35 ± 1.8 kgf·m} [253 ± 13.0 lbf·ft]

2-Step tightening [wet]

Piston pin

Connecting rod twist

Connecting rod bend

Tor qu e

Unit: mm [in.]

L

L

C

C

3.94

[ ]

0.05

100

C

L

[ ]

3.94

100

0.05

C

L

0.0020

0.0020

C

D

D

C

0.05 [0.0020]

Unit: mm [in.]

Surface plate

100 [3.94]

Loading...

Loading...