5-9

Chapter 5 DISASSEMBLY OF BASIC ENGINE

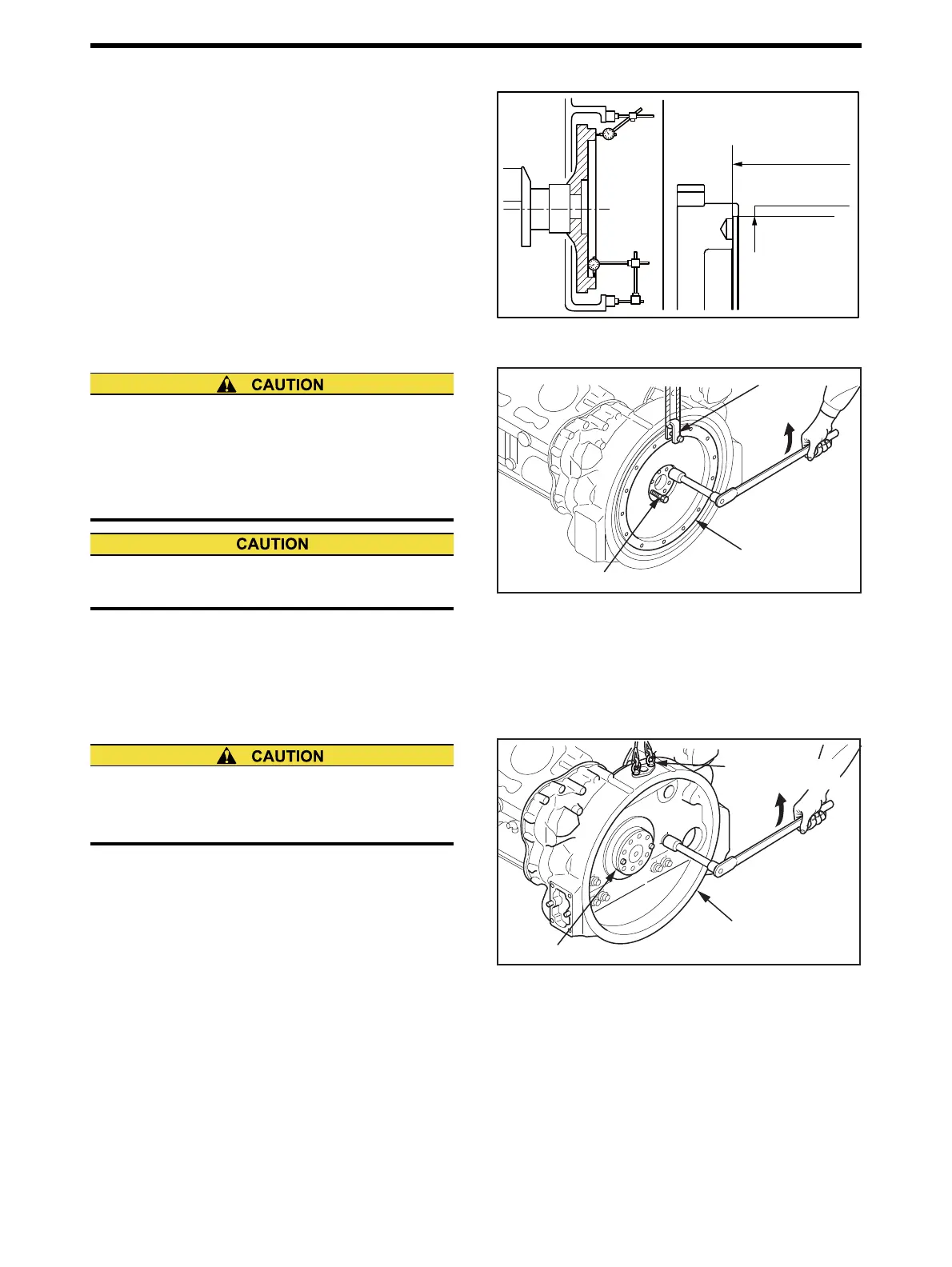

2.1 Flywheel Face and Radial Runout - Measure

Measure the face and radial runouts of the flywheel, and

know the current condition.

For the measurement procedure, refer to "Flywheel Face

and Radial Runout - Measure" of "ASSEMBLY OF BASIC

ENGINE."

Flywheel Face and Radial Runout - Measure

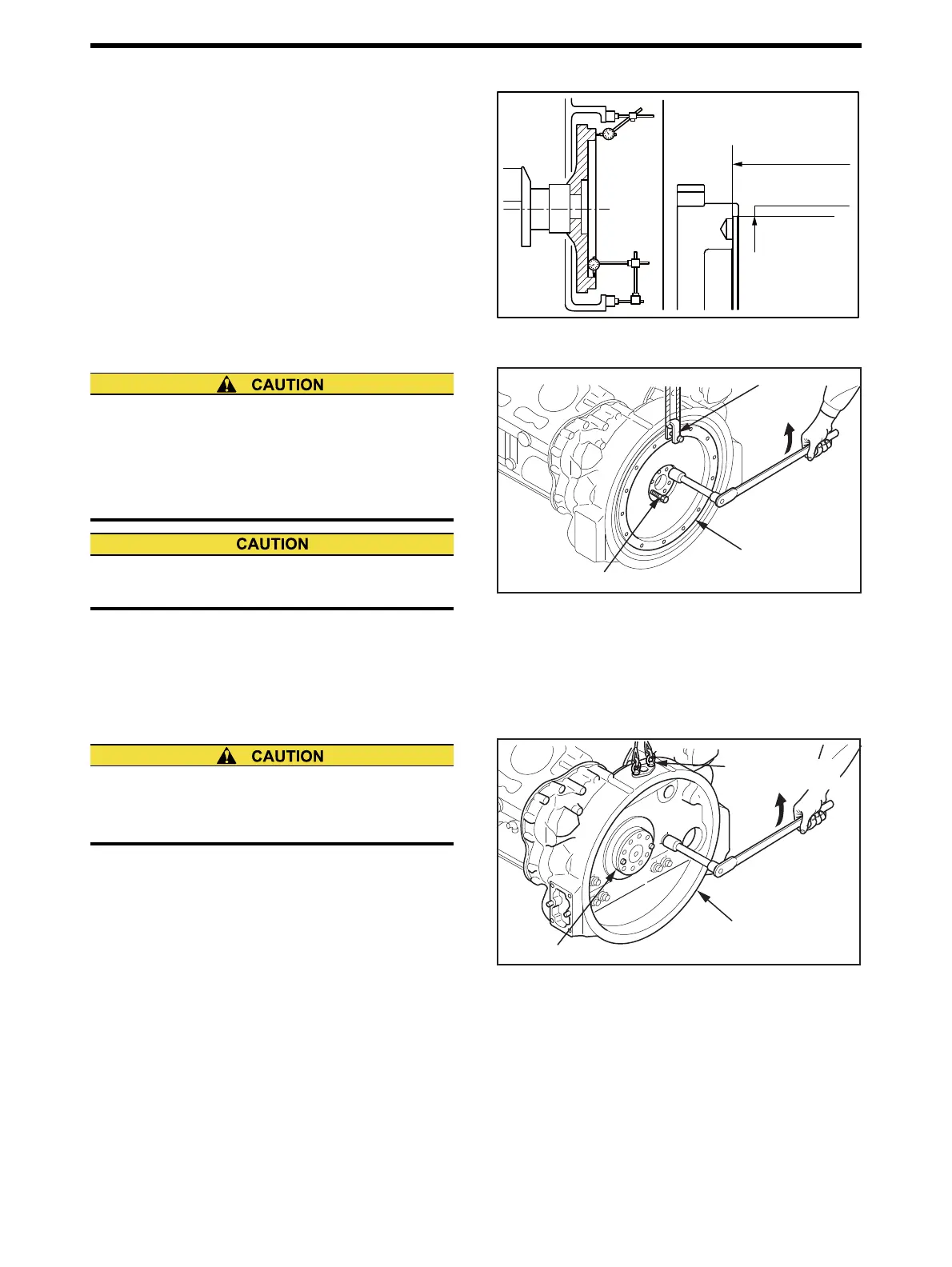

2.2 Flywheel - Remove

(1) Hitch a sling to the flywheel to prevent it from falling.

(2) Screw two jack bolts evenly into the jack bolt holes,

and remove the flywheel.

Flywheel - Remove

2.3 Timing Gear Case - Remove

(1) Hitch a sling to the timing gear case to prevent it from

falling.

(2) Lift the timing gear case to disengage the dowel pins,

and remove the timing gear case.

(3) Remove the oil seal from the timing gear case.

Note: Do not reuse the removed oil seal.

Timing Gear Case - Remove

Face runout

measuring plane

Radial runout

measuring plane

(a) Be careful not to drop or bump the flywheel.It can,

not only cause damage to parts, but also lead to

personnel injury.

(b) Be careful not to cut your hands with the ring gear

when pulling-out the flywheel.

Be sure to remove the pickups before removing the

flywheel.

Jack bolt (M12 × 1.75 mm)

Sling

Flywheel

Be careful not to drop or bump the timing gear case.It

can, not only cause damage to parts, but also lead to

personnel injury.

Oil seal

Eyebolt

P/N:05930-00200

(M12 × 1.25 mm )

Timing gear case

Loading...

Loading...