7-16

Chapter 7 ASSEMBLY OF BASIC ENGINE

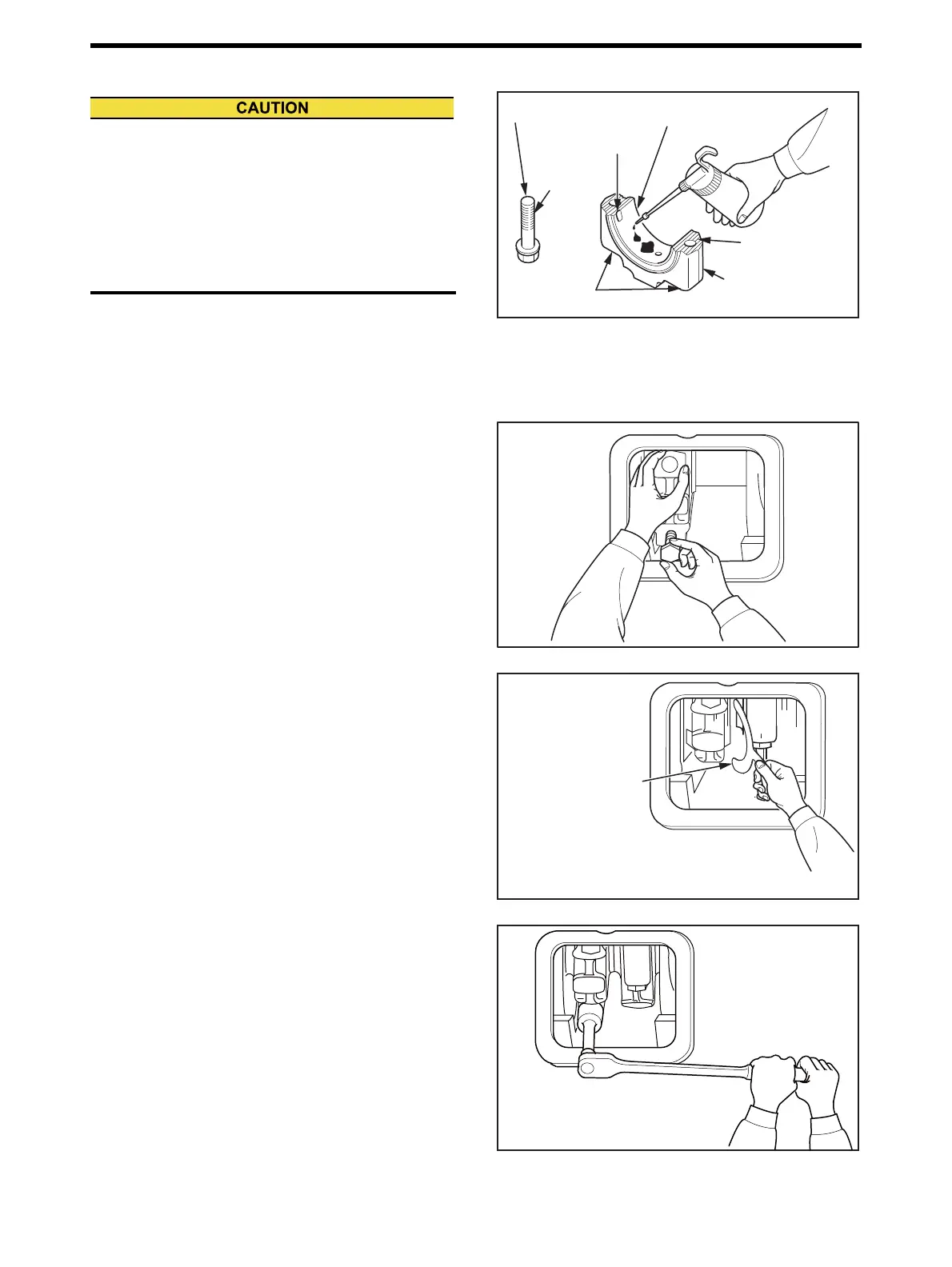

2.12 Connecting Rod Cap - Install

(1) Install the lower connecting rod bearing, aligning its

lug with the lug slot of the connecting rod bearing cap.

(2) Apply engine oil to the connecting rod bolt threads and

seating surface, and the sliding surface of the lower

connecting rod bearing shell.

Connecting Rod Cap - Install (1)

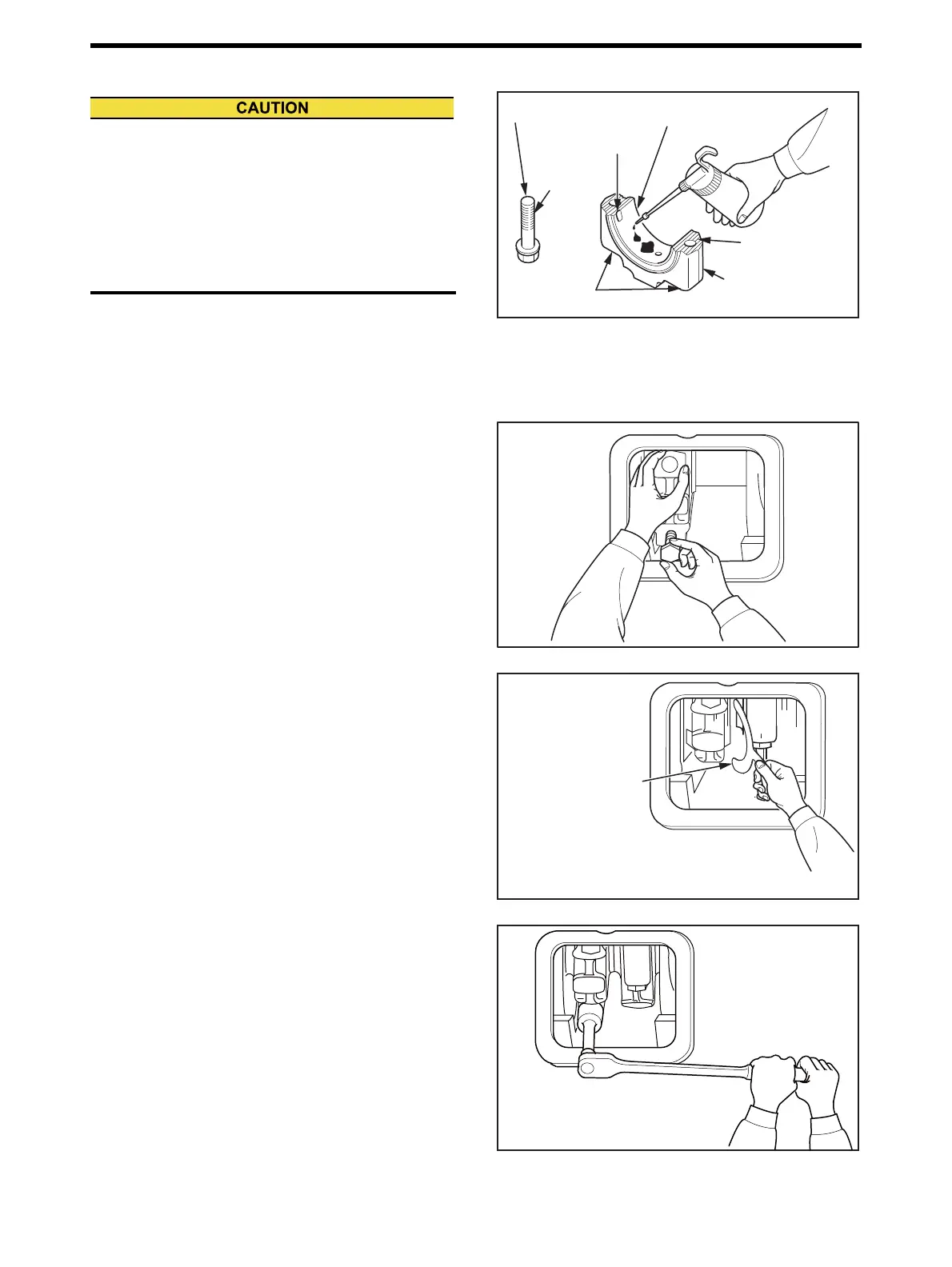

(3) Install the connecting rod cap to the connecting rod so

that that the matching numbers on the connecting rod

cap and the connecting rod are the same and on the

same side.

(4) Hand tighten the connecting rod bolts.

Connecting Rod Cap - Install (2)

(5) Align the connecting rod and rod cap side faces to

ensure the rod end play.

Note: To ensure the minimum end play, the connecting rod

gauge may be inserted between the two connecting

rods for adjustment.

(6) Measure the connecting rod end play, and adjust the

end play to the range of the standard value.

Connecting Rod Cap - Install (3)

(7) Tighten the connecting rod bolts to the specified

torque.After tightening to the specified torque, loosen

the bolts completely and tighten again to the specified

torque.(2-time tightening method)

Measure the end play again.

Note: To tighten the connecting rod bolts with the angle con-

trol tightening, follow the steps below.

(a)Tighten the bolt to a snug torque of 147±7.4 N•m

{15± 0.75kgf•m} [108±5.46 lbf•ft].

(b)Further rotate the bolt 45±3 degrees.

(c)Loosen all bolts, and then angle controlled tighten

them again.(2-time tightening method)

Connecting Rod Cap - Install (4)

(a) Make sure that the matching numbers on the con-

necting rod and the connecting rod cap are on the

same side and in alignment.

(b) When installing the connecting rod cap, make sure

that dust or metal particles are not caught in the

serrations, bolt seating surfaces and the bolt

threads.

Lug groove

Threaded

portion

Bolt's seat face

Lower connecting rod

bearing

Connecting rod bolt

Connecting rod cap

Serrated portion

P/N 0.5 mm [0.020 in.] : 32691-01500

0.6 mm [0.024 in.] : 32691-01600

Connecting rod gauge

Ensure the end play

with a connecting

rod gauge

343±17 N·m {35±1.8 kgf·m}

[148±13 lbf·ft] [Wet]

2 times tightening method

Loading...

Loading...